|

US$32,000.00-50,000.00

|

1 Set

(MOQ)

|

Basic Info.

Making Method of Parison

Extrusion-Blow Molding

Automation

semi-automatic

Computerized

Non-Computerized

Certification

CE, ISO9001:2008, QS, GMP

After-sales Service

online

Capacity

9 piece one time

Transport Package

Wooden Box

Specification

7.93*1.82*2.24m

Production Capacity

400set/Year

Product Description

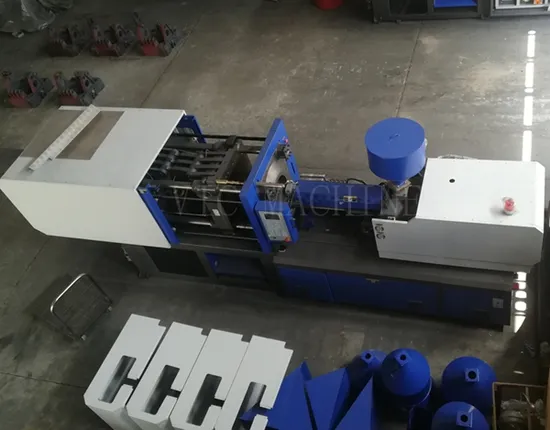

Plastic bottle making machine plastic injection moulding machine

1-body; 2-electromechanical for oil pump; 3-clamping cylinder; 4-firm plate;5-clamping mechanism; 6-pull rod; 7-hooking template; 8-firm board; 9-plasticizing barrel;10 - hopper; 11 - acceleration box; 12 - electric idea;

13 - injection cylinder; 14 - metering assembly; 15 - moving cylinder; 16 - console

Features

The working principle of the plastic injection moulding machine is similar to that of the syringe for injection.

The plastic injection moulding machine is to inject the plasticized molten state (ie, the viscous flow state) into the closed cavity by the thrust of the screw (or plunger). The process of obtaining the product after curing and setting.

Injection molding is a cyclic process, and each cycle mainly includes: quantitative feeding - melt plasticizing - pressure injection - filling mold cooling - mold extraction. After removing the plastic part, the mold is closed again for the next cycle.

Injection moulding machine operation items:

Injection moulding machine operation items include three aspects: control keyboard operation, electrical control system operation and hydraulic system operation.

The injection process action, the feeding action, the injection pressure, the injection speed, the selection of the ejection type, the monitoring of the temperature of each section of the barrel, the adjustment of the injection pressure and the back pressure are performed.

Generally, the molding process of the screw type injection moulding machine is:

Firstly, the granular or powdered plastic is added into the barrel, and the plastic is melted by the rotation of the screw and the outer wall of the barrel, and then the machine performs the mold clamping and the injection seat forward. The nozzle is placed close to the gate of the mold, and then the pressure oil is introduced into the injection cylinder to advance the screw, thereby injecting the melt into the lower temperature closed mold at a high pressure and a relatively high speed. Time and pressure are maintained (also known as holding pressure), cooled, and solidified, and the product can be opened by mold opening (the purpose of holding pressure is to prevent backflow of molten material in the cavity, replenish material into the cavity, and ensure the product Has a certain density and dimensional tolerance). The basic requirements for injection molding are plasticization, injection and molding. Plasticization is the premise to achieve and guarantee the quality of molded products, and in order to meet the molding requirements, the injection must ensure sufficient pressure and speed. At the same time, due to the high injection pressure, a correspondingly high pressure is generated in the cavity (the average pressure in the cavity is generally between 20 and 45 MPa), so a sufficient clamping force must be obtained. It can be seen that the injection device and the clamping device are key components of the injection molding machine.

Main data:

| Specification | Unit | ZSJ2400PET |

Injection Unit

| Screw Diameter | mm | 65 |

| Screw L/D Ratio | L/D | 1:18.5 |

| Injection Capacity In Theory | cm3 | 830 |

| Injection Weight | g | 755 |

| Shot speed | g/s | 242 |

| Plasticizing capacity | g/s | 34 |

| Injection Pressure | Mpa | 121 |

| Screw Speed | rpm | 0-200 |

| Clamping Unit | Clamping Force | KN | 2400 |

| Toggle Stroke | mm | 480 |

| Space Between Tie-bars | mm | 520*520 |

| Max Mould Height | mm | 520 |

| Min Mould height | mm | 220 |

| Ejector Stroke | mm | 110 |

| Hydraulic Ejection | KN | 70 |

| Others | Max. Pump Pressure | Mpa | 16 |

| Pump Motor Power | kw | 22 |

| Heater Power | kw | 24.73 |

| Machine Dimensions (LxWxH) | m | 7.93*1.82*2.24 |

| Machine Weight | t | 11.5 |

Component of the injection machine:

| Name | Brand |

| Controller | TAI WAN Techmation 7 color screen |

| Vane pump | America Sunny |

| Main direction valve | America Vickers |

| Proportional valve | Taiwan Dofluid /HNC |

| Hydraulic five star motor | Ttaly Intermot /Zihyd |

| Core puller | One set |

| Linear Transducer | America/France |

| Electric equipment | Japan Omron /Fuji |

| Lubrication | Automatic |

| Main airproof element | Taiwan /Japan |

| Electric motor | Bei jing /zhong da |

More pictures

Production line diagram

Bottle mould

Cap mould

Package

Factory view

Certification

After-sales service

>>

Auto Part Oxygen Sensor Impala Malibu XL Cadillac XTS for Chevrolet OE 12627139

>>

High Quality Vertical Automatic DK-III Gear Type Tapping Machine

>>

High Quality Electrical Metal Stainless Steel Corner Fillet Weld Grinder Sander Polisher

>>

Copy Printing Writing News Paper A4 Paper/ Cultural Paper Machine

>>

Kaftan Dubai Abaya Kimono Robe Muslim Hijab Dress Abayas For Women Caftan Maroca

>>

Z4132 China Heavy Metal Drilling Machine with Ce Certification

>>

OEM 11417610026 TC1020 Timing Chain for BMW N13 B16 A F30 1.6L

>>

Automatic continuous plastic bag heat sealing machine

>>

Canada standard high quality balcony double glazed sliding glass door for hotel room with good sound insulation

>>

Nc Rotary Sheeter with Stacker

>>

Fast CNC Horizontal Machining Center Hmc1000 for Mold and Die Manufacturing

>>

Gjb30-40 Small Vacuum Dairy Homogenizer

>>

New Arrival Cute Cartoon Rabbit Handheld Portable Beauty Lighting Mirror Winter USB Hand Warmer

>>

Manufacturer YFMA-800 Automatic High Speed Paper Box Thermal Laminating Heat Press Machine

>>

Handheld Small Portable Plasma Sheet Metal Cutter Cutting Machine Plasma Cutter Cut55 for Distributor

>>

Retro Breakfast Series toaster kettle Set Home multipurpose breakfast machine heating toaster spit driver

>>

GS High Efficiency Rotor Sand Mixer Green Sand Molding Plant

>>

Garlic Peeling Splitting Production Line Electric Garlic Peeling Machine

>>

Sali Manufacture Segment Sintered Diamond Grinding Cup Wheel

>>

Factory Stainless Steel Clamp for Pipe Leak Repairing