Basic Info.

Model NO.

G2040F-A 20000W

Application

Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry, Aerospace

Cooling System

Water Cooling

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Gantry Type

Laser Classification

Solid Laser

Laser Technology

Laser Control Fault Cutting

Cutting Thickness

0.5mm-80mm

Energy Consumption Level

Low

Transport Package

Wrapping Film and Plastic Soft Bag

Specification

10800*3100*1800

Production Capacity

5000pieces/Year

Product Description

Product Description

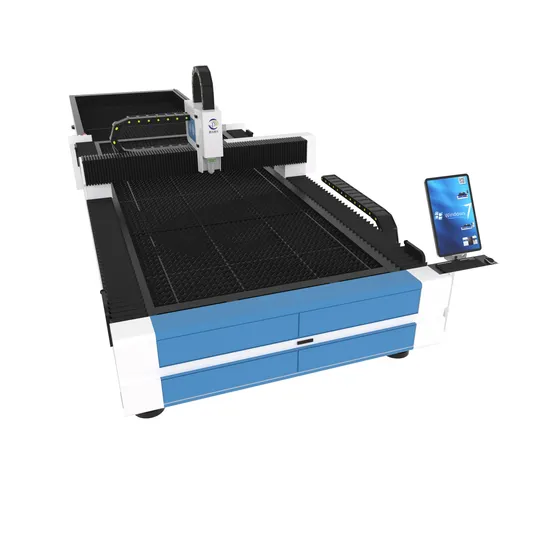

The 2040 Exchange Platform Laser Cutting Machine is the epitome of precision and efficiency, perfectly blending affordability with simplicity. Designed for those who seek excellence, this cutting-edge machine ensures you recover your investment swiftly while delivering flawless performance. Its user-friendly operation makes it an indispensable tool in any production line, promising unmatched cost-effectiveness and productivity.

Product Features

1. Boasting a laser-specific control system, this machine delivers rapid responses and precise control, setting a new standard in laser cutting technology.

2. Experience lightning-fast cutting speeds paired with outstanding cross-section quality, all while enjoying reduced operating costs-efficiency and savings in one brilliant package.

3. Equipped with a fully automatic exchange platform, this system redefines convenience with its intelligent and highly efficient operation.

4. The integrated design of the electrical cabinet ensures an optimized layout that not only saves space but enhances overall functionality seamlessly.

5. Featuring a high-precision CNC operating system and a high-end private service motor, it guarantees stable, efficient, and top-tier performance.

6. Every series comes equipped with air pressure detection monitoring, a chiller, and a laser alarm, promising unparalleled safety and reliable control.

Product Parameters

| Name&Model | Laser Cutting Machine G2040F-B/G2060F-B |

| Working Area | 2000mm*4000mm/2000mm*6000mm |

| Laser Power | 1500W/2000W/3000W/6000W/12000W/20000W//30000W |

| Machine Structure | Stable & strong welded bed with high temperature annealing |

| Beam | Aviation aluminum/Integrated cast aluminum beam |

| Applicable Material | Carbon Steel Stainless Steel Etc( Metal Laser Cutting Machine ) |

| Laser Source Brand | MAX/RAYCUS |

| Key Selling Points | Automatic |

| Warranty | 2 years |

| Condition | New |

| Moving Speed | 120m/min |

| X axis travel (mm) | 2030 |

| Y axis travel (mm) | 4050/6050 |

| Z axis travel (mm) | 100 |

| Max acceleration | 0.8G |

| Position Accuracy | ±0.03mm |

| Repositioning Accuracy | ±0.02mm |

| Computer | Industry Computer |

| Transfer method | Gear rack dual drive |

| Working Voltage | 380V,3phase,50hz/60hz(customized) |

| Dimension | 10800*3100*1800mm/15100*3100*1800 |

| Graphic Format Supported | AI, PLT, DXF, BMP, DST DWG, LAS, DXP |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Applicable Material | Metal Steel Carbon Copper |

Detailed Photos

Steel square tube + steel plate welded bed

The machine bed is expertly crafted from high-rigidity materials, offering a substantial weight that forms a robust foundation for optimal machine tool performance, ensuring precision in processing. After meticulous heat and surface treatments, the bed boasts impressive high hardness and wear resistance, guaranteeing longevity. It effectively combats thermal deformation, providing the machine tool with remarkable anti-seismic, anti-torsion, and anti-fatigue properties.

Shandong Pengwo Laser Technology Co., Ltd. is prominently situated in Dezhou City, Shandong Province, and since its inception in 2005, has specialized in pioneering research and development of laser processing equipment. This esteemed service provider is dedicated to delivering intelligent manufacturing solutions tailored to laser processing needs. Through relentless development and accumulation of cutting-edge technology, the company has emerged as a premier domestic authority in laser application equipment solutions. Today, it proudly operates two expansive production bases located in Dezhou Tianqu New District and Pingyuan County, encompassing over 80,000 square meters.

The company excels in manufacturing a diverse range of laser processing equipment, including medium and high power laser cutting machinery, laser welding, and laser cladding technologies. Renowned for its automated, tailored, and versatile R&D and production prowess, the company has successfully delivered top-tier laser cutting solutions to a wide array of industrial enterprises both domestically and internationally. Its esteemed clientele spans sectors such as automotive parts, kitchen and bathroom hardware, electronics, electrical systems, smart homes, engineering machinery, building bridge templates, prefabricated structures, special power transmission towers, coal mining, petrochemical equipment, and other precision manufacturing domains. The innovations are progressively extending into new energy vehicles, aerospace advancements, and high-end agricultural machinery, further solidifying its industry leadership.

After Sales Service

Comprehensive Installation Training Options (Choose from 3 tailored experiences):

A. Experience seamless installation, operation, maintenance, and troubleshooting with our comprehensive training resources. We provide detailed videos and user manuals in English, enhanced by expert technical guidance available through email, fax, phone, Messenger, WhatsApp, and more. Rest assured, our team is here to support you every step of the way, addressing any challenges you face with installation, use, or adjustment.

B. Embrace an immersive learning experience in China, accompanied by comfortable accommodations. Revel in the benefits of China's robust after-sales service team, dedicated to your success and satisfaction.

Our proficient engineers and staff are fluent in English, ensuring seamless communication to resolve any concerns. We can also organize flight arrangements for your convenience.

Optimal Training Duration:

3-7 working days (highly recommended) for a complete installation, commissioning, and training package. This includes expert guidance on maintenance and operation at your personal work site, all complimentary from the supplier. While the supplier provides these premium services, the customer will need to cover the supplier's round-trip airfare, as well as costs related to food, accommodation, local transportation, translation services, Internet access, communication, and visa fees, according to actual documentation.

Certifications

To ensure the exemplary production of high-quality fiber laser cutting machines, we meticulously oversee the entire process, starting from the meticulous selection of raw materials and components. We rigorously control product quality, adhering to stringent international standards. This enables us to gain prestigious qualifications, underpinning our commitment to establishing robust quality policies and ambitious goals.

Quality system: Proudly accredited with the ISO9001:2005 International Quality System Certification, a testament to our unwavering dedication to excellence in quality management.

Quality policy: Our ethos centers on deriving benefits through strategic management, ensuring survival through unmatched quality, achieving returns through exceptional service, and driving development through relentless innovation.

Quality goals: We are dedicated to achieving 100% customer satisfaction. Our targets include attaining a product one-time installation qualification rate exceeding 99.5% and an impeccable product unpacking qualification rate of 100%.

Exhibition

FAQ

Q1. When was your factory established?

We have been specialized in the R&D, manufacturing and intelligent manufacturing solutions of laser processing equipment since 2005, mainly focusing on laser processing equipment such as fiber laser cutting, laser welding equipment, laser cladding equipment, etc.

Q2. What should I do if there is a problem with this machine during the warranty period?

The quality assurance period is 12 months from the date the goods arrive at the destination port. Except for man-made damage, we are responsible for providing accessories free of charge during the warranty period. After the quality assurance period, if you need to repair or replace parts, you must pay.

Q3. How to install and use?

We will provide training videos and English user manuals for installation, operation, maintenance and troubleshooting for the machine. When you encounter installation, use or adjustment problems, we will provide technical guidance by email, fax, telephone/Messenger/WhatsApp, etc.

Q4. What should I do if there is an after-sales problem?

You can directly describe your problem to the after-sales staff. China's strong after-sales service team. Our engineers (employees) can communicate and solve problems in English, and can be arranged once a day per person when you need it. If I need to go to your place to help, I will quickly arrange to go there and quickly fly to help you.

Q5. How about wholesale price?

If you are a wholesaler, distributor or agent, please contact us to get wholesale price.

>>

Flexible Paper Straw Machine

>>

Fire Cylinder Filling Machine for HFC-227ea/HFC-236fa/CO2/Perfluorohexanone

>>

Conventional Universal Cylindrical Grinding Machine M1360 China High Precision Surface Grinder Machine

>>

GM2216 High Precision Gantry Machining Centers with Fast Delivery and Reliable CNC Solutions 3/4/5 Axis Grinding Machine Factory

>>

Automatic Silicone Rubber Vulcanizing Molding Compression Plate Heat Hydraulic Press Vulcanizer Machine with CE Certificate

>>

an Isolated Regenerative Self-Rescue Device with Compressed Oxygen as Gas Source

>>

Industrial Inflatable Toy Side Sealing Machine Kids Toys Doll Hair Sewing Machine

>>

Double Tempered Glass Mosquito Screen Sliding Folding Aluminum Alloy Window Aluminium Frame Sliding Glass Window Grill Design

>>

Wholesale Stainless Steel Tek Screw Flat Countersunk Phillips Head Drilling Screws Self Drilling Screw

>>

Fast Land Transport LCL Export From China to Russia Moscow

>>

Factory Price Wholesale China Supplier Mini Split Air Conditioner 12000Btu

>>

sawdust belt conveyor

>>

SH Large format UV printer, large UV printer, UV flat printer

>>

DIN 1.4767 FeCrAl Alloy Iron Chromium Foil Metal Foil 0.075mm*600mm

>>

Factory Direct Genuine Authorization 1: 64 Simulation Diecast Alloy Model Electric Racing Car

>>

Wholesale 1: 64 Hot Educational Diecast Model Pull Back Car Alloy Die Cast Car Metal Vehicle Toys for Children Boys Kids Metal Toy Die Cast Airplane Model

>>

Private Label Handheld Edge Grip 2 Stage Portable Ceramic Smart Manual Knife Sharpener

>>

Computer Parts Shredder and Plastic Shredder for Plastic Recycling Plant

>>

Taijia rebar locator pachometer detector wall scanner integrated concrete protective layer tester

>>

Thinyou Foldable Projection Curtain 84inch16: 9 Portable Home Outdoor Polyester Projector Screen