|

US$20,000.00-60,000.00

|

1 SET

(MOQ)

|

Basic Info.

Computerized

Computerized

Certification

CE, ISO9001:2008

After-sales Service

1 Year

Raw Material

PE HDPE Plastic Pellets

Temperature Control

Omron

Extrusion Type

Co-Extrusion

Screw Heating

Ceramic Heating

Outputput

100kg-800kg Per Hour

Transport Package

Film Packed, 20gp 40hq

Specification

SJ65/33 60/38 75/33

Production Capacity

200 Sets Per Year

Product Description

Product Description

1. PE HDPE PPR pipe extrusion machine line is a specialized equipment used for manufacturing high-density polyethylene (HDPE) and polypropylene random copolymer (PPR) pipes.

2. This machine line is designed to produce pipes of various diameters and lengths, meeting the specific requirements of different applications.

3. The extrusion process involves melting the raw material, such as PE or PPR granules, and forcing it through a die to create a continuous pipe shape.

4. The machine line consists of several components, including an extruder, a die head, a vacuum calibration tank, a haul-off unit, and a cutting machine.

5. The extruder is the main part of the machine, responsible for melting and homogenizing the polymer material before it is extruded through the die.

6. The die head determines the final shape and dimensions of the pipe, and it can be customized to produce pipes of various sizes and specifications.

7. The vacuum calibration tank is used to cool and solidify the extruded pipe, ensuring its dimensional accuracy and preventing deformation.

8. The haul-off unit pulls the pipe at a constant speed, controlling its tension and preventing sagging or stretching during the production process.

9. Finally, the cutting machine cuts the extruded pipe into desired lengths, ready for packaging and distribution.

10. PE HDPE PPR pipe extrusion machine line is widely used in industries such as construction, agriculture, and plumbing, providing a cost-effective and efficient solution for pipe manufacturing.

Detailed Photos

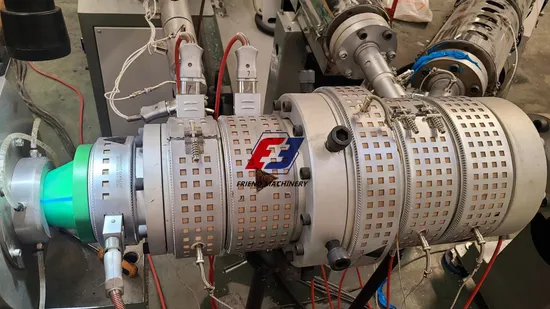

Single screw extruders(2-4 co-extruders)

1. with vacuum loader and hopper dryer

2. ABB/DELTA frequency inverter

3. Omron temperature control

4. Siemens Beide motor

5. Ceramic heating device

6. high quality screw and gearbox

7. output can be from 80kg/h to 600kg/h

PE pipe Mold

common speed and high speed design

pipe layer can be ABA,ABC

Vacuum forming machine and water spray cooling machine

1. length can be 4000mm, 5000mm, 6000mm, 9000mm.

2. good cooling and calibration effect.

3. including vacuum pump and water pump

Haul off machine

1. ABB frequency inverter

2. belt can be 2 claws to 6 claws

Pipe cutter machine

1. no dust design

2. cutting pipe smooth surface

3. phneumatic control

Final product

Product Parameters

Pipe Range

| Detailed Pipe Diameters

|

16mm-63mm

| 16mm, 20mm, 25mm, 32mm, 40mm, 50mm, 63mm

|

75mm-250mm

| 75mm, 90mm, 110mm, 150mm, 160mm, 200mm, 250mm

|

Packaging & Shipping

Company Profile

Our Advantages

FAQ

Q1: If I need more information, how to contact you?

Send me your demands, we will send back detailed machine specifications with working video.

Q2: How to buy your machine?

We send detailed machine quotation to you, if you are satisfied, we will make Proforma invoice for you, payment terms: 30% deposit, after machine testing good, 70% before shipment.

Q3: What about warrenty?

In some countries, we have agent and one year warrenty.

Q4: How can I believe your factory and company?

You are welcomed to ask authority to visit our factory and machine, we are real factory.

Q5: Do you have other service?

We can send engineer to your factory to install the machine and offer training. Each year, if we have machines technical improvements, we will inform clients.

Q6:Where is your factory located?

Our factory is in Zhangjiagang City which is nearby shanghai port, about 2 hours car driving, if you want to visit our factory, we can pick you up from airport or train station.

>>

Stand Seaworthy Packing Wall Block Machine with CE Certification

>>

Reinforced Wire Cage Welding Machine for Concrete Pipe

>>

Professional Wholesale Zkbbs SUS 304 A2-50 Equivalent Low Small Head Cap Screws

>>

Car Battery Storage Battery: Mf N150 Just Brand Battery

>>

c-section steel press plate, u-shaped toothed press plate beam clamp, steel structure toothed beam clamp, 0203

>>

frankfurter sausage Making Machine Salami production line sausage production line

>>

Multi Colors 2meter Plastic Construction Barricades

>>

Multi Blade CNC Bridge Saw Stone Slab Cutter Granite Block Cutting Machine for Processing Paving Stone, Kerbstone, Cobblestones

>>

PC Bottle Injection Blow Moulding Machine with Ce Approved

>>

Truck Cargo Lift Cargo Lifting Equipment

>>

Classic Metal Type C USB Flash Memory Disk for Android and MacBook

>>

Dt Latest Model Agglomerator Suitable for Soft PVC/HDPE/LDPE

>>

Factory Price Automatic Belt Leather Fabric CNC Polyester Mesh Cutting Slitting Machine

>>

Warm up time 1-2min fast warm-up A4 Hotlaminator Coldlaminator Office Laminating Machine Manual Table Pouch Laminator

>>

Professional Manufacturing Rubber Sheet Splitting Machine

>>

Automatic 3 in 1 Pure Mineral Drinking Production Bottling Plant Line Filling Bottle Water Making Machines Mineral Water Liquid Filling Machine

>>

Concrete thickness rebar size rebar corrosion detector

>>

B&R X20CP1486

>>

Yg6 C122 Insert Tungsten Cemented Carbide Brazed Tips

>>

Double Wheel 20KHz Ultrasonic Sewing Machine For Protection Suit Welding