| US$3.00 | 10 Pieces (MOQ) |

| Company Name | Guangdong Engineering plastics Industries(Group)Co,Ltd |

| Brand | Guangdong Engineering plastics |

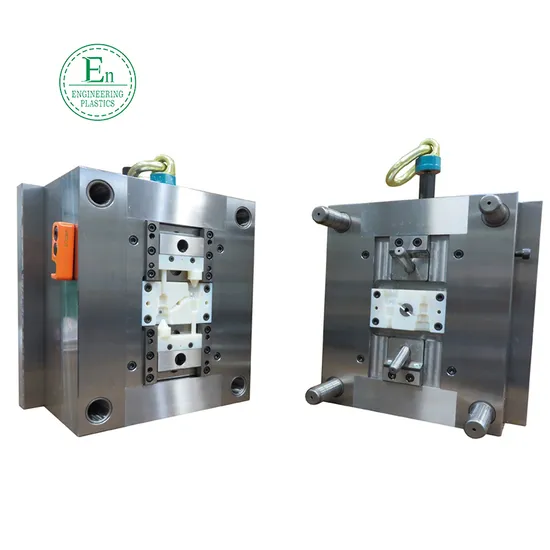

| Main Product | Precision mold, Injection mold, Extrusion mold, Injection plastic products, etc |

| Injection Machine (Double Color) | 88T, 90T, 120T, 168T, 200T,250T,380T,420T,600T,800T,1000T,1200T,1500T,2200T,2800T,3000T |

| Application | Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household goods, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc |

| Mould Base | LKM Standard,DME Standard,HASCO Standard,FUTABA Standard,Self-made Standad ,etc. |

| Mould Material | 718H/738H/718/738/NAK80/S136/S136H/2738/2316/H13/P20/2344ESR/8407/SKD-61, etc |

| Moud Precision | +/-0.01mm |

| Mould Life | 100K-1000K shots |

| Mould Cavity | Single cavity, multi-cavity |

| Runner System | Hot runner and cold runner |

| Manufacturing Equipments | Guangdong Engineering plastics company has OWM:Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc |

| Plastic Raw Material | Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC, PMMA(Acrylic),TRU,EPDM,NBR, Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc. |

| Color | white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc |

| Surface Treatment Tech | Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture, Sanblasting,Gilding, UV Painting… |

| Product Drawings | 2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures |

| Lead time | 15-30 working days for injection moulds,plastic products according to quantity |

| Quanlity System | ISO 9001, RoHS Srandard, etc |

| Our Spirit | "Engineering Plastics" can be used instead of "Steel"! Science and technology will change the future! Guangdong Engineering Plastics Industries Company! |

| Other | 24 hours instant and comfortable customer service! |

| Shipping status notification during delivery! | |

| Regular notification of new styles & hot selling styles! |