|

US$10.00-120.00

|

1 Piece

(MOQ)

|

Basic Info.

Application

Metal Cutting Machine, Metal Processing Machinery Parts

Artcraft

Turning and Milling

Turning Type

Outer Circle Turning, Inner Circle Turning, Surfac

Design for Manufacturability

Provided

Transport Package

Customized Box

Specification

As the requirmented

Production Capacity

60000PCS/Month

Packaging & Delivery

Package Size

100.00cm * 80.00cm * 10.00cm

Package Gross Weight

2.000kg

Product Description

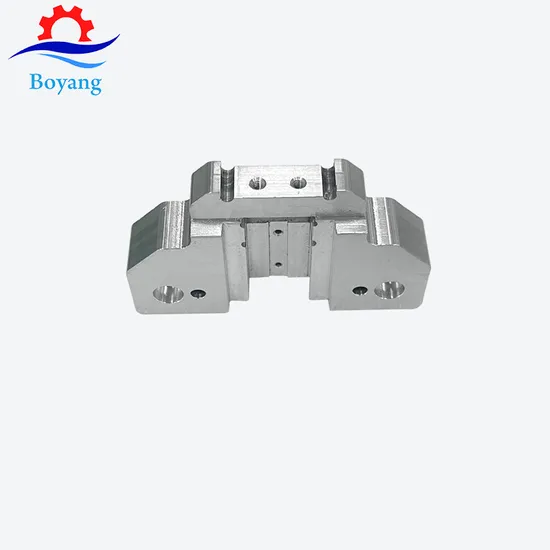

High-Quality Solutions in Multiple Materials Precision Aerospace Non-Standard Parts Customization

Product Description

Our high-precision CNC machined aluminum parts are designed for aerospace, automotive, industrial, and electronics applications. Manufactured using advanced 5-axis CNC machining, these parts offer ±0.01mm tolerance, excellent strength, and corrosion resistance. We provide customized sizes, surface finishes, and colors to meet diverse industry needs.

Why Choose Us?

ISO9001 Certified Manufacturing - Strict quality control and traceable production

Premium Aerospace-Grade Aluminum - 6061-T6, 7075-T6 and other aluminium materia for high strength and durability

Various Surface Finishes - Anodizing, Sandblasting, Brushing, and Polishing and so on

100% CMM Inspection - Full material certification and dimensional accuracy reports

Custom Order Support - Small batch production and rapid prototyping available

Product FeaturesHigh Precision: Advanced CNC machining ensures tight tolerances and complex geometries.

Material Versatility: Capable of processing aluminum, titanium, stainless steel, superalloys, and composites.

Surface Treatment Options: Anodizing, plating, passivation, and other protective coatings to enhance durability.

Strict Quality Control: Comprehensive inspection processes, including CMM measurement and non-destructive testing.

Customization & Prototyping: Tailor-made solutions to meet specific aerospace engineering requirements.

Product Parameters

| Item | Details |

| Material | 6061-T6 / 7075-T6 Aerospace-Grade Aluminum |

| Tolerance | ±0.01mm |

| Surface | Anodizing, Sandblasting, Brushing, Polishing |

| Colors | Silver, Black, Blue, Red (Customizable) |

| Industries | Aerospace, Automotive, Electronics, Industrial Equipment |

| Lead Time | 5-12 Days (Depending on Order Quantity) |

Recommended Applications

| Industry | Application |

| Aerospace | UAV Frames, Aircraft Structural Components, Engine Brackets |

| Automotive | Racing Car Components, Lightweight Chassis, Heat Sinks |

| Industrial Equipment | CNC Machine Parts, Precision Fixtures, Hydraulic Components |

| Electronics | LED Heat Sinks, Precision Enclosures, Communication Device Frames |

Detailed Photos

Our Processing Advantages:Advanced Manufacturing Capabilities:

Equipped with state-of-the-art CNC machines, multi-axis machining centers, and automated production lines.

Expert Engineering Support:

Experienced technicians and engineers ensure optimal designs and efficient production processes.

High-Efficiency Production:

Short lead times with a focus on precision and consistency.

Comprehensive Testing & Certification:

We adhere to the highest aerospace standards, ensuring product reliability and safety.

Global Customer Support:

Serving clients worldwide with customized aerospace solutions and technical consultation.

At Boyang, we are committed to providing high-quality, precision-engineered aerospace parts that exceed industry expectations.

Contact us today to discuss your project and discover how our expertise can support your aerospace manufacturing needs.

Customization Process

Customization Process for Machinery Parts Manufacturing:

1:Initial Consultation and Requirement Gathering

Please send us your desired machinery part requirement such as dimensions, material, tolerances, application, and more.We can give you the more accurate and timely quotation as soon as the detailed the information you give us.

2:Design and Prototyping

After understanding your requirements, our team of experienced engineers will design the part using advanced software. A prototype is then produced for review and approval.

3:Material Selection and Procurement

Once the design is approved, the appropriate material for the part is selected and procured. The material selection depends on the part's application and your specifications.

4:Manufacturing and Quality Control

The approved design is sent to our state-of-the-art CNC and other machines for production. Throughout the manufacturing process, our quality control team ensures that the part is being produced to the exact specifications and maintains the highest quality standards.

5.Finishing and Inspection

After manufacturing, the part undergoes finishing processes like deburring, polishing, or coating as your different requirements. The finished part is then inspected for quality and precision.

6.Delivery

Upon passing the final inspection, the customized machinery part is carefully packaged and delivered to your there timely.

7:After-sale Service

The shipment of goods does not mean the end of our cooperation relationship, it is just the beginning, we provide good after-sales service, look forward to growing with you in the long -term business.

After Sales Service

1.Product Installation and Setup

After a customer purchases a product, they might need assistance with installing or setting it up. Our team is available to guide them through this process, either through detailed manuals, online tutorials, or direct customer support.

2.Product Training and Demonstrations

For more complex products, we provide training sessions and demonstrations to help customers understand how to use the product effectively and safely.

3.Maintenance and Repairs

We offer regular online maintenance guiding services to keep the product in its best condition. If there are any issues, our team of skilled technicians is on standby to provide quick and efficient repair services.

4.Software Updates and Upgrades

If the product involves software or firmware, we provide regular updates to ensure it's running the latest version. This includes security patches, bug fixes, and feature enhancements.

5.24/7 Customer Support

We provide customer the solution within 24 hours , that can be done via phone, email, or live chat.

6.Warranty and Return Policies

We stand by the quality of our products. That's why we offer a comprehensive warranty. If a product itself doesn't meet our quality standards, we have a return and exchange policy in place to ensure customer satisfaction.

7.Customer Feedback and Improvement

We value our customers' feedback. We're always looking to improve our products and services, and customer feedback is integral to that process.

FAQ

Q1:Is Boyang a factory ?

A:Yes ,Boyang is a original processing base with two factories.It has a high speed development in these years.

Q2:Is the Sample suitable?

A:Sample can be provided free.We can deduce the sample fee in formal orders.

Q3:Do you offer heat treatment and surface treatment?

A:Yes.We provide the whole process of the parts according to the specific request.

Q4:Is small MOQ available?

A:Our MOQ is 1 PC for your flexible demand.

Q5:How about the delivery time ?

A:According to the detailed processing demand ,our PMC will make a production planning for your shorter lead time .

Q6:How about the shipping terms?

A:According to the demand time and weight, we will choose the appropriate mode of transportation.

Q7:What is the Payment terms?

A:Amount<=500$, 100% TT in advance

Amount>=500$,30%TT in advance,70% before shipping .

Q8:How to process an order?

A:*Sending us your drawing or sample ,or an idea.

*Approving the craft and process details.

*Testing sample

*Formal orders

*Providing photos and videos are provided in each processing step .

*Shipping

Q9:How about your after-service?

A:Our service does not stop even the order is completed.

We offer one year product warranty for all parts,we offer free replaceable ones in case of the quality of the product itself.

Our service will provide solution within 24 hours.

Application

Machinery parts can have a wide range of applications across various industries.

Automotive Industry

Machinery parts are critical to the automotive industry. They are used in the manufacturing of engines, transmissions, suspensions, and other crucial components of vehicles.

Aerospace Industry

In the aerospace industry, precision machinery parts are used in the production of aircraft engines, control systems, and other aircraft components. The high standards of this industry require parts that are extremely reliable and durable.

Electronics Industry

The electronics industry relies on machinery parts for the production of various devices like computers, televisions, and smartphones. These parts are often smaller and require a high degree of precision.

Construction Industry

Machinery parts are essential for the construction industry, being used in various equipment like excavators, bulldozers, and cranes. These parts need to be robust and durable to withstand the rigorous demands of construction work.

Medical Industry

In the medical industry, machinery parts are used in the production of medical devices and equipment, such as MRI machines, CT scanners, and surgical robots. These parts must meet stringent quality and safety standards.

Chemical Industry

Mechanical parts have a wide range of applications in the chemical industry. They are used in various chemical equipment and systems to ensure precise, reliable, and safe operation.

Mianyang Boyang Technology Co., Ltd. is committed to serving customers in different fields and growing with customers together.

>>

2024 New 72V2kw High Power Motor/Electric Scooter/City Bike

>>

380kg home and construction small articulated front shovel china diesel mini skid steer loader for sale

>>

Split Air Heating Solar Collector System for Seafood Drying

>>

Wholesale Cheap Polyester Bedding Throw Pillow Inserts 18 X 18 Pillow Core

>>

Good reputation femo plant/factory

>>

high quality auto car accessories bodykit body kit sets for TOYOTA landcruiser prado 2018 upgrade to black bodykit body kit

>>

Waterproof En124 Manhole Cover Plastic Composite Manhole Cover SMC Square Manhole Cover

>>

OEM Die Casting Spare Parts with Excellent Quality

>>

1668 LED light skmei touch screen led watch instructions women sports watch wholesal digital gold watch

>>

Hot Selling 1220*2440*18mm Natural Fancy Plywood for Furniture and Decoration

>>

Promotion Gift Office Gradient Color Finish PU Leather Journal Notebook

>>

Rear Hatch Lift Support Shocks Gas Strut gas Spring for 2000-Toyota ACR30

>>

84177743 Auto front grille FOR GMC TERRAIN 2018-2019

>>

ICE125ASX2 Dual Channel Digital Audio Power Amplifier Module Board

>>

Hotel Guest Room Wooden Folding Luggage Rack

>>

wholesale price sublimation printing yoga pants custom fitness printed yoga leggings for women

>>

Solar Garden LED Light Post with Durable Galvanized Pole2.

>>

Best selling fluorite briquette dryer/ shisha charcoal mesh band dryer

>>

Outdoor Folding Knife Aluminum Alloy Handle Pocket Knife Jungle Survival Self-defense Portable self-defense Knife

>>

1j0955119, 955290001, 1h0955119 Wiper Motor Fits Lincoln, Mercury, Volkswagen