|

US$5,000.00-50,000.00

|

1 Set

(MOQ)

|

Basic Info.

Drying Function

With Drying Function

Automatic Grade

Automatic

Computer Control Panel

Computer Control Panel

Product Name

Egg Tray Machine

Raw Material

Waste Paper Waste Books, Newspapers

Electricity Power

20-150kw

Voltage

220/380/440V/50Hz/60Hz

Mold Material

Aluminum Molds or as Per Customer′s Need

Dryer System

Multi-Layer Dryer or Brick Dryer

Drying Type

Sun Drying, Metallic Dryer, Brick Dryer

Labor Force

2-8 Operators

Transport Package

in Container

Specification

Depends on final capacity

Production Capacity

700-4000PCS/H

Product Description

Paper Egg Tray Making Machine Pulp Molding Reclycling

Egg Tray Machine Introduction:

Automatic and semiautomatic egg tray pulp molding machine and production line It is used for making large quantity easy shape products, like paper egg tray, fruit tray, coffee cup carrier tray, bottle tray, wine tray, egg carton with lid, disposable medical products and industrial packaging products etc. Paper Egg Tray Machine Capacity: 350pcs/h, 700pcs/h, 1000pcs/h, 1300pcs/h, 1800pcs/h, 2000pcs/h, 2500pcs/h, 3000pcs/h, 4000pcs/h, 4500pcs/h, 5000pcs/h, 6000pcs/h. Product Type: Egg Tray Machine Process Type: Paper Pulp Molding Production Raw material: waste paper, waste cardboard, newspapers etc. Any type waste paper without plastic. Boiler fuel heating type: diesel, coal, natural gas, or LPG Power Requirement: 20KW-220KW Voltage needed: 220V-440V Workshop requirement: 100--850m2 Machine Model: WY350--WY6000 Workers Requirement: depends on different capacity machine Brand Name: Wanyou Origin Place: Shandong, China After-sales service system: Engineers are available for dispatching abroad to install the machine Certificate: CE Egg Tray Machine Flow-chart:

Raw material--hydrapulper-- Pulp mixing--Forming--Drying-- Hot Press--Packing--Stock

Pulping System

1. Put the raw material and water into the hydraulic pulper, you will get the paper pulp after mixed 10-20 minutes.

2. Pulp pump will transfer the finished paper pulp into the slurry pool.

3. The pulp pond beater will mix the pulp concentration.

4. The pulp pump will transfer the pulp into forming machine.

Molds Forming System

1. The molding machine is to absorb the pulp to the molding mold, which is through the suction of the vacuum system to absorb the excess water into the gas-water separation tank, and then pump the water to the tank for storage.

2. The molding mold absorbs the pulp and then forms it. and then the transfer mold takes out the finished product and sends it to the drying tray.

Drying System

1.Heat source: natural gas, diesel, liquefied petroleum gas and other combustion liquids and gases.The transmission mode adopts industrial transmission chain to drive the net plate transmission, which runs in the drying line.

Technical Specification of Paper Egg tray machine

Reciprocating Forming

| Egg Tray Mold Quantity | 2pcs | 3pcs | 4pcs | 12pcs(3pcs*4) |

| Raw material | Waste paper | Waste paper | Waste paper | Waste paper |

| Egg tray Capacity | 700pcs/hour | 1000pcs/hour | 1300pcs/hour | 2000pcs/hour |

| Net weight per piece (gram) | 70g-75g | 70g-75g | 70g-75g | 70g-75g |

| Waste paper consumption | 0.06ton / hour | 0.1ton / hour | 0.13ton / hour | 135kg/ hour |

| Water Consumption | 0.1ton/hour | 0.15ton / hour | 0.2ton / hour | 0.5ton / hour |

| Natural Gas Consumption of Dryer | 25cbm/h | 35cbm/h | 50cbm/h | 60cbm/h |

| Worker requirement | 3-4workers | 4-6workers | 4-6workers | 5-7workers |

| Power Requirement | Without dryer | 30KW | 40KW | 45KW | 70KW |

| With dryer | 45KW | 60KW | 65KW | 80KW |

| Area of workshop | Without dryer | More than 100 M² | More than 120 M² | More than 150 M² | More than 200 M² |

| With dryer | More than 240 M² | More than300M² | More than 320 M² | More than 400M² |

| Container Requirement | Without dryer | 20ft*1 | 40ft*1 | 40ft*1 | 40ft*1 |

| With dryer | 40ft*2+20ft*1 | 40ft*2+20ft*1 | 40ft*3 | 40ft*3+20ft*1 |

Remarks:

1. The Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g).

2. Workshop size is for reference only and could be adjusted according to actual size of client's plant.

3. The above specification is for reference only, due to continuous technology development, data will be updated from time to time.

4. Pulp Molding Equipment are non-standard equipment, we are able to provide customized solution according to specific requirements from customer.

5. Welcome to contact us anytime, our professional team will provide more effective help and supports for you. |

|

| Egg Tray Mold Quantity | 12pcs(3pcs*4) | 16pcs(4pcs*4) | 24pcs(3pcs*8) | 32pcs(4pcs*8) |

| Raw material | Waste paper | Waste paper | Waste paper | Waste paper |

| Egg tray Capacity(pcs/hour) | 2000 | 2500 | 3000 | 4000 |

| Net weight per piece (gram) | 70-75 | 70-75 | 70-75 | 70-75 |

| Waste paper consumption | 150kg/ h | 150kg/h | 188kg/h | 225kg / hour |

| Water Consumption | 0.45ton / h | 0.6ton/h | 0.68ton/h | 0.9ton / h |

| Natural Gas Consumption of Dryer | 75cbm/h | 90cbm/h | 110cbm/h | 120cbm/h |

| Boiler model (natural gas fuel Kcal) | 800*103 | 1000*103 | 1200*103 | 1500*103 |

| Worker requirement | 5-7workers | 5-7workers | 8-10workers | 8-10workers |

| Power Requirement | Without dryer | 70KW | 80KW | 100KW | 100KW |

| With dryer | 100KW | 120KW | 130KW | 150KW |

| Area of workshop | Without dryer | More than

200 M² | More than 200 M² | More than 250 M² | More than 250 M² |

| With dryer | More than 400M²

Dryer18M | More than 400M²

Dryer20M | More than 520M² dryer30M | More than 520M²

Dryer32M |

| Container Requirement | Without dryer | 40ft*1 | 40ft*1 | 40ft*1 | 40ft*1 |

| With dryer | 40ft*4 | 40ft*4 | 40ft*5 | 40ft*5 |

Remarks:

1. The Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g).

2. Workshop size is for reference only and could be adjusted according to actual size of client's plant.

3. The above specification is for reference only, due to continuous technology development, data will be updated from time to time.

4. Pulp Molding Equipment are non-standard equipment, we are able to provide customized solution according to specific requirements from customer.

5. Welcome to contact us anytime, our professional team will provide more effective help and supports for you. |

Hot Press Molding Machine for paper egg carton, electrical product tray, sprinkler tray, industrial packaging tray

Certificate of egg tray machine

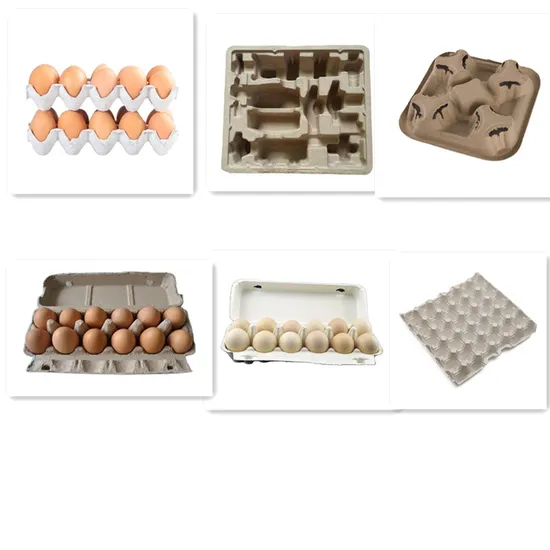

End Products Of Paper Egg Tray Machine

Paper egg trays are the end products of egg tray plant. Egg trays are good protection shell for eggs during transporting and storage. Usually, the egg trays has 30 holes. Esle, there are 10 holes egg trays, 12 holes egg trays, 24 holes egg trays etc. What's more, if you change the mould, the machine can be used to make apple trays, egg cartons and so on.

Raw materials to make egg trays: original wood pulp, craft paper, A4 paper, paper box, old newspaper, old books and other kinds of recycled papers.

Delivery

| Payment Terms | |

| Trade terms | FOB Qingdao | |

| Quotation Validity time | Within 30days | |

| Delivery time | Depends on final egg tray machine capacity type | |

| Payment term | BY T/T 40%DEPOSIT+60%BALANCE. | |

| Time of payment | When the deposit is paid, the machine will begin to be produced. And the balance should be paid by the consignee (the buyer) before the delivery. | |

| Warranty time | Two years after the Egg tray machine received. | |

| TERMS OF DELIVERY | FOB Qingdao Port, China | |

| Package | In container | |

| Installation & Training | |

| 1. Usually, all installation and debugging work will be done before shipment. 2. If the buyer wants to Install the debugging term, the seller will arrange one people instructs the installment(all travel ticket and hotel charge by buyer and engineer charge USD100/day ) 3.We will dispatch 1 engineer to direct the installation and debugging of the equipment if needed. And the engineer will train the workers on site. | |

| |

FAQ:

Our productionline has Fully Automatic and Semi Automatic two types , both have computer control system .

1. What is Semi Automatic type ?

If only order The 1st and 2nd compulsory parts , that's Semi Automatic because you'll have to do the work of drying up egg tray manually;

2. What is Fully Automat type ?

Meaning: the production line includes the Drying system and the whole procedure can be done Automatically .

Of course, the price and the required work space would have big difference from the semi-automatic type.

3. Quality

--- Our machines use UK Technics and part of the components are Germany-made (ex: Ball valve) .

-- Our machine is made by Tooling NOT by Welding , insuring a minimum of 10 years' lifespan .

-- The Egg tray moulds material is Aluminium which can keep the fixed shape much better than that made of rubber material.

--- 99.9% of Success rate: Even if there is a failed egg tray , just throw it back to Pulping area and it can be re-used avoiding waste ;

--- Our machine has been sold to worldwide for over 10 years with continued re-order by some customers with their business grow .

4. What kind of material we can use as the raw material?

Any kind of waste paper like old newspaper,magazines,books,A4 paper etc, and easy to get

5. What kind of Fuel can be used for the whole production line?

Coal, natural gas, and dieseal oil.

6. What kind of products can be made by this machine?

All paper package such as paper egg tray, egg carton,egg box, fruit tray, bottle tray, cup tray, consumer product package, medical disposable container etc.

7. Are you a manufacturer?

Yes, Jinan Wanyou has been fabricating pulp molding machine since 2008. We are one of the most important pulp molding machine manufacturer in the world, and we are famous pulp molding machine manufacturer in China, providing high quality and production capacity pulp molding machinery at reasonable prices to the world.

Our Services

(1)Technical consultation ;

(2)Detailed design of customer workshop ;

(3)Installing and testing the whole production line before shipment;

(4)Training engineers and workers;

(5)Supplying spare part for long time;

(6) Online services anytime.

>>

Flat Head Self Drilling Screws Yellow Zinc Phillips DIN7504p

>>

New Product Long-handled Electric Bath Scrubbing Brush Lazy Massage Bath

>>

football club OEM Custom high quality quick dry Soccer Uniform Football Jerseys Soccer jersey Set Quick Dry

>>

China-Russia Musical Instruments Warehouse Service

>>

PP Non Woven Strip Clip Cap Bouffant Head Cover Making Machine

>>

Factory Price Welding Steel Pipe Production Line Round Tube Making Machine

>>

Wholesale 1ton Super Sack Type C Sling Tote Bag 1200kg PP Bulk Bag Anti-Static FIBC Jumbo Bag Conductive 1.5ton Big Bag

>>

Outdoor Wholesale Ocean Pack 5L 10L 15L 20L Swimming 500d PVC Waterproof Dry Bag for Travel and Sport

>>

Vertical Square Column Metal High Precision Drilling Machine Z5125

>>

6mm Black Mil Spec 3D Spacer Air Mesh Fabric Wight of 450GSM for Molle Gear

>>

Chaoyang Good Luck/Weishi 14.00R20 off-road tires 1200/1400R20 tires

>>

High-Performance Shaft Metal Ends CNC Facing Centering Machine for Railway Axle

>>

High Quality Easy Installation Zinc Alloy Black Bronze Wall Mounted Robe Hanger Clothesstainless Steel Wall Clothing Hook

>>

Factory Direct Sale Car Chassis Abnormal Sound Simulator Price

>>

Engine cylinder cushion 571-9902 5719902 Suitable for CAT engine C18, C15, 336D, 390DL models

>>

harmless treatment equipment for diseased and dead pigs, cattle and sheep, harmless treatment equipment for livestock and poultry waste from slaughtering, meat meal processing equipment

>>

Carbon fiber reinforced PA material, high strength, high wear resistance, can be customized

>>

Wooden Hangers Wooden Products Fast Drying Equipment Microwave Dryer

>>

4-inch water filter 4040 FRP membrane shell for water treatment

>>

UHMWPE Dump Truck Liner Sheets /Trailer Bed UHMWPE Liner Sheet / UHMWPE Coal Bunker Liner