|

US$45,000.00-50,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Function

Storage Pressure Vessel, Separation Pressure Vessel, Heat Pressure Vessel, Reaction Pressure Vessel

Storage Medium

Customized

Pressure Level

Customized

Branch Office

California, USA

Product Description

Vessel Capacity m³: 5.8 Material: S31603+Q345R Design pressure MPa: 4.5 Design temperature ºC: 200 Work pressure MPa: 3.5 Work temperature ºC: 160 Medium: Hydrogen, catalyst, phenol Working life: 10 years Jacket Capacity m³: 1.0 Material: Q345R Design pressure MPa: 0.6 Design temperature ºC: 200 Work pressure MPa: 0.5 Work temperature ºC: 160 Medium: steam Heat exchange area m2: 13.7 Coil tube Capacity m³: 0.13 Material: S31603 Design pressure MPa: 0.6 Design temperature ºC: 150 Work pressure MPa: 0.5 Work temperature ºC: 50 Medium: cycling water Heat exchange area m2: 12.2 Total weight Kg: 9338

With the demand for environmental protection in the new era, hydrogenation is the most environmentally friendly chemical process, gradually replacing the process of severe pollution that is not conducive to environmental protection. It is applied in the three-phase catalytic hydrogenation of gas, liquid, and solid, which is a reaction process between hydrogen and other compounds. It is divided into single-sided hydrogenation and double-sided hydrogenation. The process of high-pressure hydrogen gas consumption to low-pressure is accompanied by hydrogenation heat, also known as exothermic reaction. Hydrogen is a flammable and explosive substance, and there must be safety measures for the hydrogenation process.

Magnetic coupling drive with static sealing, zero leakage, long service life, simple installation, safe and environmentally friendly.

| MODEL | FCHA200-600L | FCHA800-2000L | FCHA2500-5000L | FCHA6000-10000L | FCHA12000-20000L |

| CAPACITY | 200-600L | 800-2000L | 2500-5000L | 6000-10000L | 12000-20000L |

| WORK PRESSURE MPa | -0.1-10.0 | -0.1-10.0 | -0.1-10.0 | -0.1-10.0 | -0.1-8.0 |

| WORK TEMPERATURE C° | -15-320 | -15-320 | -15-320 | -15-320 | -15-320 |

| rpm | 0-320 | 0-320 | 0-320 | 0-320 | 0-320 |

| Motor power KW | 3.0-11.0 | 11.0-22.0 | 15-37.0 | 22.0-55.0 | 37.0-75.0 |

| Main materials | 09MnNiDR/16MnDR (low-temperature steel), 15CrMoR (high-temperature steel), stainless steel S30408/S32168/S31603, S39042, titanium material, duplex steel, shackle material, Hastelloy alloy, zirconium material, Monel, and other materials used for explosive composite plates. |

| Heating form | Jacketed thermal oil, jacketed steam, outer half pipe, inner coil pipe. |

| Mixing form | Turbine self suction, disc turbine, asymmetric turbine, four wide blade, axial flow combination self suction. |

| Shaft sealing form | Magnetic coupling drive with static sealing, zero leakage, long service life, simple installation, safe and environmentally friendly. |

| Remarks | Other special requirements, touch screen intelligent control, program control, and connection to DCS systems shall be designed, manufactured, and configured according to user needs. |

| LUHAO Chemical Machinery Co. Ltd | | | | | | | | | | | | |

| | | | | | | | | | | | |

| Pressure Vessel Design Information Collection Table | | | | | | | | | |

| | | | | | | | | |

| | | Vessel | Jacket (Coil) | | | | | | | | | |

| Work Medium | Name | | | | | | | | | | | |

| Components | | | | | | | | | | | |

| Density (Kg/m³) | | | | | | | | | | | |

| Characteristics | | | | | | | | | | | |

| Viscosity (cP) | | | | | | | | | | | |

| Flow Velocity(m³/h) | | | | | | | | | | | |

| Design pressure (Mpa) | | | | | | | | | | | |

| Work pressure (Mpa) | | | | | | | | | | | |

| Design temperature(ºC) | | | | | | | | | | | |

| Work temperature (ºC) | | | | | | | | | | | |

| Wall temperature (ºC) | | | | | | | | | | | |

| Diamter (mm) | | | | | | | | | | | |

| Length (mm) | | | | | | | | | | | |

| Capacity(m³) | | | | | | | | | | | |

| Effective capacity (m³) | | | | | | | | | | | |

| Corrosion allowance (mm) | | | |

| Corrosion speed (mm/year) | | | |

| Recommended Materials | | | | | | | | | | | |

| Lowest value of average monthly temperature(ºC) | | | | | | | | | | |

| Site location | | | | | | | | | | |

| Installation condition | Indoor or Outdoor | | | | | | | | | |

| | | | | | | | | | | | | | | |

| Catalyst Volume(m³) | | | | | | | | | | | | |

| Catalyst Density(Kg/m³) | | | | | | | | | | | | |

| Heat Transfer Area() | | | | | | | | | | | | |

| Coil Specification | | | | | | | | | | | | |

| Basic Wind Pressure(Mpa) | | | | | | | | | | | | |

| Seismic Basic Intensity | | | | | | | | | | | | |

| Ambient Temperature(ºC) | | | | | | | | | | | | |

| Site Type | | | | | | | | | | | | |

| Operating Mode | | | | | | | | | | | | |

| Insulation Materials | Name | | | | | | | | | | | | |

| Thickness | | | | | | | | | | | | |

| Density (Kg/m³) | | | | | | | | | | | | |

| Seal Requirements | | | | | | | | | | | | |

| Liquid Level Gauge | | | | | | | | | | | | |

| Emergency Cut-off | | | | | | | | | | | | |

| Static Electricity Removal | | | | | | | | | | | | |

| Anti Eddy Current Requirement for Liquid Outlet | | | | | | | | | | | | |

| Installation and Mantainance Requirements | | | | | | | | | | | | |

| Expected Useful Life (years) | | | | | | | | | | | | |

| | | | | | | | | | | | | | | |

| Safety accessories | | Vessel | Jacket (Coil) | | | | | | | | | |

| Location | | | | | | | | | | | |

| Type | | | | | | | | | | | |

| Specification | | | | | | | | | | | |

| Quantity | | | | | | | | | | | |

| Set pressure(Mpa) | | | | | | | | | | | |

| Burst disc | | | | | | | | | | | |

| Burst pressure(Mpa) | | | | | | | | | | | |

| Safety discharge(kg/h) | | | | | | | | | | | |

| | | | | | | | | | | | | | | |

| Agitator | Type | | | | | | | | | | | | |

| Impeller Diameter(mm) | | | | | | | | | | | | |

| Speed(r/min) | | | | | | | | | | | | |

| Motor | Model | | | | | | | | | | | | |

| Power(kw) | | | | | | | | | | | | |

| Explosion Proof Grade | | | | | | | | | | | | |

| Speed reducer | | | | | | | | | | | | |

| | | | | | | | | | | | | | | |

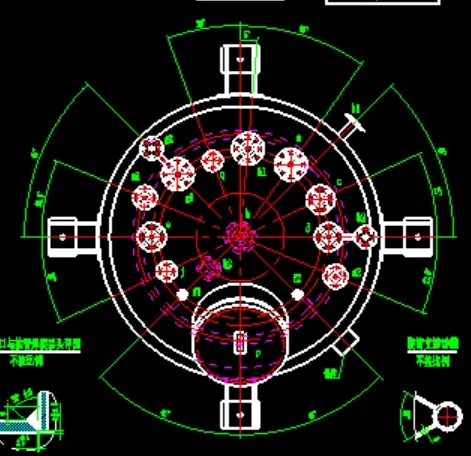

| Piping Table | | | | | | |

| No. | Dimension | Pressure | Connection Size Standard | Connection Surface Type | Function | | | | | | |

| | | | | | |

| a | | | | | | | | | | | |

| b | | | | | | | | | | | |

| c | | | | | | | | | | | |

| d | | | | | | | | | | | |

| e | | | | | | | | | | | |

| f | | | | | | | | | | | |

| g | | | | | | | | | | | | | | |

| h | | | | | | | | | | | | | | |

| j | | | | | | | | | | | | | | |

| k | | | | | | | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | | | |

| | | | | | | | | | | | | | | |

| Other Requirements if any | | | | | | | |

https://luhaochemreactors.en.made-in-china.com/product-list-1.html

>>

Anti-counterfeit Printable Holographic Security Digital QR Code Barcode Labels for Authentication

>>

Pressure Steam Sterilization Equipments Mecan CE 75 Liters Laboratoire Pharmaceutical Autoclave with Factory Price

>>

5.8GHz/2.4GHz Dual-Band Signal Booster for WiFi, Fpv or Dji Drone Signal Extender

>>

perkins lift pump T417445 T417414/genuine original engine parts

>>

Luxury Ceiling-Mounted Touch Control 3 Speeds Circle Kitchen Range Hood

>>

Quiet-Operating Handheld Garment Steamer for a Peaceful Ironing Session

>>

Microlandscape Simulation Frog Sculpture Fish Tank Garden Rockery Bonsai Landscaping Decoration Green Toad Decoration

>>

2020 Unique Design Nickel Fitting Fashion Style Polyester Lining Material Genuine Leather Women Sling Bag

>>

250ml Pet Boston Round Plastic Bottle with 24/410 Neck Finish Lid

>>

fish canning machine food cans sealing machine

>>

BENTLY 167699-02 DCS/PLC CONTROLLER IN STOCK

>>

Garbage Truck 10-15 Cbm Heavy Duty Truck Refuse Collection Compactor Truck Sinotruk HOWO Euro 2 for Africa

>>

Die Casting aluminum pressure fuel oil tank

>>

Hisense Vidda C1 4K Projector Vidda C1 PRO 4K Triple Laser Projector Home Cinema Full 3D Vidda Hisense Projector

>>

Free Shipping! ! New Mini Chinese 4.0 M3 Cubic Meter Cement Concrete Self-Loading Articulated Mobile Mixing Mixer Truck with Pump for Low Price Sale

>>

LDPE Foam Machine Making EPE Foam Net Rod Stick Pipe Profile

>>

Medical Operation Lamp for Surgical (7412)

>>

Glass fiber aging and acid alkali resistant nylon flange gasket insulation cushion block injection production

>>

High Quality Red Color Coated Lubricated Aluminium Foil Material for Wrinkle Wall Container

>>

Auto Glass for KIA Sorento 5D SUV 2002- Windshield