|

US$50,000.00-300,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Process Usage

Metal-Cutting CNC Machine Tools

Movement Method

Contour Control

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

Economical CNC Machine Tools

Certification

GS, CE, RoHS, ISO 9001

Product Name

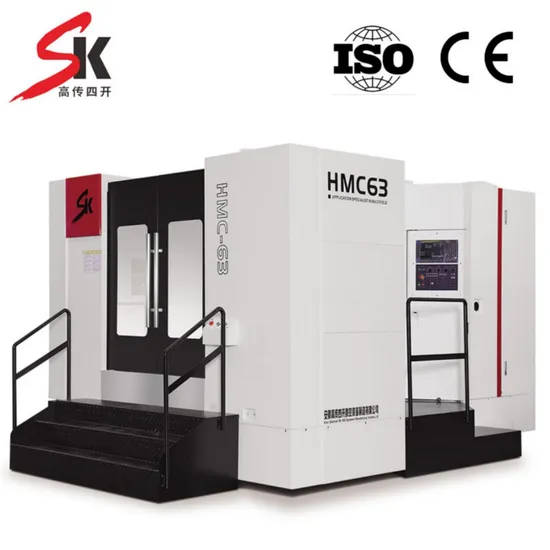

Hmc1250 4 Axis Horizontal CNC Milling Drilling Mac

Applicable Industries

Building Material Shops, Manufacturing Plant

Marketing Type

Direct Markteing / Distributor

Video Outgoing-Inspection

Provided

Core Components

System /Spindle/Ballscrew

Tool Magazine Capacity

40t

Type

Horizontal Machining Center

Exported Country

Russia, Germany, American, Indian, SA, Pk

Control System

Fanuc, GSK, Simens, Mitsubishi, Hnc

Transport Package

Suitable for Sea Shipping

Specification

3400x5300x2600

Production Capacity

300 Sets/Year

Product Description

Horizontal CNC Machining Centre

1.1 DESCRIPTION

1.2 FEATURE

Classic column moving structure, the overall base is rigid enough, oil-water separation structure. The side layout of the manipulator tool magazine is isolated and protected, and the tool change is fast and reliable. The X-direction guide cover has a large inclination angle, double-sided spiral + chain rear chip removal, and the chip removal is smoother. Three-axis heavy-duty roller linear guide, good acceleration performance, suitable for high-efficiency processing. Spindle configuration with high rigidity, wide-area high-torque spindle motor, strong re-cutting capability. Full-featured, flexible configuration, convenient expansion, to meet different customer requirements. Fully servo-driven dual-pallet exchange device, the movement is smoother and more stable.

1.3 PARAMETERS

| Specification | Unit | HMC50 | HMC63 | HMC80 | HMC100 | HMC125 |

| X/Y/Z axis | mm | 660/580/620 | 1050/750/900 | 1300/1000/1000 | 1600/1000/1400 | 2000x1300x1400 |

Distance from spindle end to

workbench centre | mm | 130-750 | 150-1050 | 200-1200 | 250-1650 | 350-1750 |

Distance from spindle centre to

workbench surface | mm | 100-680 | 100-850 | 120-1120 | 120-1120 | 120-1420 |

| Workbench size(L*W) | mm | 500x500 | 630×630 | 800x800 | 1000x1000 | 1250x1250 |

| Max. workbench load | Kg | 700 | 1200 | 2000 | 2200 | 3500 |

| Workbench divisions | mm | 1°/0.001° | 1°/0.001° | 1°/0.001° | 1°/0.001° | 1°/0.001° |

Max. workpiece turning diameter on

workbench | mm | 800 | 1400 | 2000 | 2200 | 2600 |

| T-slot(number - width -spacing) | Mm | 5-18-100 | 5-22-125 | 5-22-160 | 5-22-200 | 7-22-160 |

| Spindle tapered bore (type / installed size) | mm | BT40 | BT50 | BT50 | BT50 | BT50 |

| Spindle speed | rpm | 8000 | 6000 | 6000 | 6000 | 60000 |

| X/Y/Z axis rapid feed | m/min | 34/34/34 | 30/30/30 | 24/24/24 | 24/24/24 | 18/18/18 |

| Maximum cutting feed | mm/min | 10000 | 10000 | 10000 | 10000 | 10000 |

| Tool change method | | Knife arm type | Knife arm type | Knife arm type | Knife arm type | Knife arm type |

| Toolholder specifications | type | BT40 | BT50 | BT50 | BT50 | BT50 |

| Tool capacity | tools | 24

Disc-type | 30

Disc-type | 30

Disc-type | 30

Disc-type | 30

Disc-type |

| Max tool length | - | Φ80 | Φ115 | Φ115 | Φ115 | Φ115 |

| Max tool dia | mm | 300 | 350 | 350 | 350 | 350 |

| Max. tool weight | kg | 8 | 18 | 18 | 18 | 18 |

| Fastest tool change time (T-T) | sec | 2.5 | 5 | 5 | 5 | 5 |

| Spindle motor | kw | 11/15 | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 |

| XYZ Positioning accuracy | mm | 0.008 | 0.008 | 0.008 | 0.01/0.01/0.008 | 0.012/0.08/0.08 |

| XYZ Repositioning accuracy | mm | 0.005 | 0.005 | 0.005 | 0.008/0.008/0.005 | 0.006/0.005/0.005 |

Worktable Positioning accuracy

1°/0.001° | mm | 5"(8")

| 5"(8")

| 5"(8")

| 5"(8")

| 5"(8")

|

Worktable

Repositioning accuracy

1°/0.001° | mm | 3"(5")

| 3"(5")

| 3"(5")

| 3"(5")

| 3"(5")

|

| Machine size:L*W*H | mm | 2600x3300x2600 | 3400/5300×2900 | 4500x6000×4000 | 4900x6500x4000 | 6000x7000x4500 |

| Machine.Weight approx. | t | 8 | 12.5 | 16.5 | 20 | 27 |

1.4 STANDARD ACCESSORIES

| 1 | 30 tool magazines | 6 | Tri-color warning light | 11 | Rigid tapping | 16 | Portable chip blowing air gun |

| 2 | Workpiece Cooling System

Spindle cooling | 7 | Machine cleaning water gun | 12 | Fully enclosed protective cover | 17 | Large flow chip flushing device |

| 3 | Automatic lubrication system | 8 | Spindle output water | 13 | Foundation screws and pads | 18 | Spindle nose labyrinth dust blower |

| 4 | Spindle air curtain dustproof system | 9 | Electric cabinet heat exchanger | 14 | Tools and Toolboxes | 19 | Oil filter |

| 5 | Working light | 10 | Network transmission and CF card function | 15 | Double helix cutter and chain plate cutter | 20 | Transformer |

After Sales Service

2. SERVICE

2.1TRAINING AND INSTALLATION

2.2 AFTER SALES 1. From the BL date, the manufacturer will implement the "three guarantees" service for the product for one year (if the user causes damage due to his own reasons, an appropriate cost fee will be charged)

2.When the machine tool breaks down, the manufacturer can accurately judge the cause of the failure and deal with it immediately after receiving the feedback information from the user; if the cause cannot be determined at that time, a reply will be given within 24hours

2.3 Package

3.Company strength

3.1 General situation

Anhui Gaochuan Sikai CNC Equipment Manufacturing Co, Ltd. (formerly Nanjing Sikai)/NanJing Newsiv Equipment Co.,Ltd was founded in 1993 and relocated to Ma'anshan, Anhui In 2021.

It is a high-tech enterprise specializing in the design and manufacturing of CNC machine tools. The company's main products have compteteiy independent intellectual property rights, and multiple series of products have obtained Jiangsu Province High tech Product Certificates.

FAQ

| FAQ |

1

| Is your company a factory or trading company ?

We are factory .It is located in JiangSu Province. |

2

| Can we visit your factory before order?

Sure.All new and old friends are welcomed to visit us at our factory. Besides,we can pick up you at the station or airport if needed. We will be very honored to help with tickets and accommodation booking. |

3

| What's the MOQ ?

One set only. |

| 4 | Do you have professional engineers ?

Yes.we have professional engineers and designers. We can provide OEM services. |

| 5 | Do you have CE certificate?

Yes , we have CE certification, machine quality is guaranteed. |

| 6 | What is your payment terms ?

30% T/T in advance , 70% T/T before shipment, Meanwhile it can be discussed according to your situation. |

| 7 | What is your delivery time ?

Our fastest delivery time for 1~5 sets will be within one month for standard model.

Special model will depends on different machines with different configurations. Please contact us to confirm it is in stock or not. |

| 8 | How is the warranty?

We will supply standard ports and accessories with our machine .

Within one year after receiving our machines, in the right operation, if there are any damaged parts or accessories, we will replace them by air or express immediately free of charge. |

Other products

5.Other products

>>

Electric Sheet Metal Shear Cutting Machine

>>

Manufacturer Direct Wholesale Super Soft 100% Polyester Raschel Mink Blanket Digital Printed World Queen Cartoon Throws Knitted

>>

Modern Black Recessed Ceiling Light with Dual Rings

>>

Factory Customized Automatic Extrusion Plastic Jerrycan Making Machine

>>

Automatic Pillow Type Wrapping Machine Bread Biscuit Candy Bar Chocolate automatic pillow candy packing machine

>>

Industry Safety Waterproof Workwear Chemical Protective PPE Disposable Coverall

>>

Auto filter production line for car ventilation system

>>

panoramic luxury houses modern indoor main exterior sound proof cheap solid wooden pivot door

>>

customized 60 gram rolling juice fruits falvor film roll small spear packaging

>>

New Atc CNC Router with Economic Price 1325 2030 Woodworking CNC Machine A4-1325-L8-E CNC Router Machinery for Cutting and Engraving

>>

Tunic women shirt blouses tops International latest tunic clothing fashion beach wear Indian manufacturer

>>

MAICTOP new arrival led headlight for hilux revo rocco 2015-2021 front lamp pick up 2 lens light

>>

High Accuracy Pipe Profile Plasma Cutter Price Best CNC Plasma H Beam I Beam Beveling Coping Cutting Machine

>>

Fully Automatic Rolling Machine for Toilet Paper Kitchen Towel

>>

Snicker Cereal Nougat Bar Production Line Snack Machine

>>

2024 Factory Hot Sales Chicken Slaughter Line Poultry Equipment Chicken Slaughtering Machine Poultri Slaughter Line

>>

4-Way Foldable Steel White Lingerie Display for Clothes Store

>>

REVO Engine Timing Chain Kit Accessories 2.0TD 2.2TD for OPEL VAUXHALL TK1003-5

>>

Masking Tape General Purpose 130-140mic White Blue Green Brown

>>

Best Selling Quality Radiator air seals 23270539