Basic Info.

Solution Temperature (°c)

760-790

Aging Temperature (°c)

260-426

Annealling&Heattreated

320hv

Transport Package

Wooden Case

Specification

max: 120kg/Coil

Production Capacity

500t/Month

Product Description

C17200 CuBe2 beryllium copper Strip / C17200 copper coil by ASTM B 601 Ohmalloy Material Co.,Ltd is the leader company in the manufacture of beryllium-copper alloys. We actively participate in all environmental studies made on all substances used in our products. Our priority is to comply with all legal regulations in force to ensure the continued existence of our products to our clients. Beryllium-Copper-alloys are mainly based on copper with a beryllium addition. High strength beryllium copper alloys contain 0.4-2% of beryllium with about 0.3 to 2.7% of other alloying elements such as nickel, cobalt, iron or Lead. The high mechanical strength is achieved by precipitation hardening or age hardening.

It is the best high-elastic material in copper alloy. It has high strength, elasticity, hardness, fatigue strength, low elastic hysteresis, corrosion resistance, wear resistance, cold resistance, high conductivity, no magnetism, no impact, no sparks, etc. A range of excellent physical, chemical and mechanical properties.

| Chemistry Content |

| Name | Main Chemistry Content | Impuity(≤wt%) |

| Be | Co | Ni | Cu | Fe | Al | Si | Pb | Total |

| QBe2 | 1.8~2.1 | / | 0.2~0.25 | Bal | 0.15 | 0.15 | 0.15 | 0.005 | 0.5 |

| QBe1.9 | 1.85~2.1 | Ti:0.1~0.25 | 0.2~0.4 | Bal | 0.15 | 0.15 | 0.15 | 0.005 | 0.5 |

| CuBe1.7(C17000) | 1.6~1.79 | Ni+Co≥0.2 | Cu+stipulated Element≥99.5 | Ni+Co+Fe≤0.6 | 0.5 |

| CuBe2(C17200) | 1.8~2.0 | Ni+Co≥0.2 | Cu+stipulated Element≥99.5 | Ni+Co+Fe≤0.6 | 0.5 |

| C17300 | 1.8~2.0 | Ni+Co≥0.2 | Cu+stipulated Element≥99.5 | Ni+Co+Fe≤0.6 | 0.2~0.6 | 0.5 |

| C17500 | 0.4~0.7 | 2.4~2.7 | / | Bal | Cu+Be+Ni+Co≥99.5 |

| C17510 | 0.2~0.6 | 0.3 | 1.4~2.2 | Bal | 0.1 | 0.02 | 0.2 | / | 0.5 |

| CuBe0.3 | 0.2~0.4 | Ni+Co:1.8~2.5 | Cu+Be+Ni+Co≥99.0 |

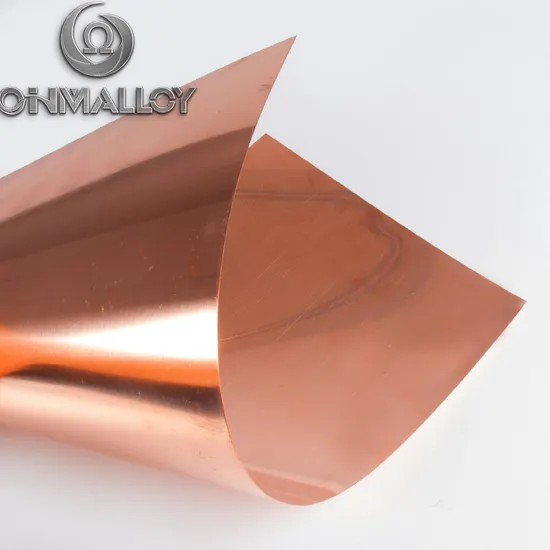

Photos

Properties

The best combination of characteristics of the copper-based alloy

The copper-beryllium alloys have a wide combination of mechanical and electrical properties which is unique for copper alloys. The mechanical strength achieved after heat treatment ranks highest amongst all the copper alloy materials and is combined with a high electrical conductivity which outperforms that of bronzes.

High Strength & Elastic Modulus

Beryllium Copper alloys can achieve very high mechanical properties after heat treatment, up to 1500 Mpa in tensile strength and hardness as high as 450 Vickers.

The strength of these alloys allow for the design of smaller, lighter components that can endure high bending stresses when used as springs material.

Production

Bending Formability

Beryllium Copper can be formed into complicated shapes in an annealed or cold-worked temper.

The highest mechanical properties can be achieved with proper heat-treatment after forming.

High Fatigue Strength

Beryllium Copper exhibits excellent resistance to fatigue under reverse bending (up to 300 MPa) which qualifies its use in applications where other alloy fail to provide the same level of reliability.

High Electrical conductivity

Beryllium Copper exhibit a high electrical conductivity ranges from 22 to 70% IACS depending on the alloys and temper. Beryllium Copper is often used as high current density spring material.

Testing

Application

Our alloys combine a range of properties particularly suited to meet the exacting requirements of many applications in the automotive, electronic, aeronautical, Oil&Gas, watch, electro-chemical industries, etc. Beryllium Copper is widely used in those fields as contact springs in various applications like connectors, switches, relays, etc

Package

>>

Primapress Germany Elgo P40t Touch Screen 3D CNC Hydraulic Bender Machine

>>

Wheel Trailer Mounted Water Well Borehole Rotary Drilling Rig (GY-150T)

>>

NEW Loreada Throttle Body Assy 22030-22041 for TOYOTA Coralla Matrix 1.8L

>>

85628000 Sharpener Presser Foot Assy for Gtxl

>>

Home Decorative Design Park Luminaire Solar Powered Outdoor Solar Garden Lamp

>>

High quality multifunction folding Gan 30W PD and QC3.0 wall charger PD plug adapter for smart Phone

>>

8851-LC-MT GE Module industrial control automation inventory quality assurance

>>

Hmc Horizontal Machining Center Hmc-800HP Fanuc Siemens Mitsubishi Controller 4 Axis 5 Axis

>>

YFMB-540 paper Processing Machinery Roll Laminator Machine

>>

55kw Bx216 Wood Slab Chipper with Low Price for Sale

>>

Perkins Timing Case 3716C522 Fits For Perkins 1004 1006 Diesel Engine Spare Powerparts

>>

Australia standard soundproof aluminum exterior french doors with integrated blinds

>>

High Quality Ductile Iron Ball Check Valve with EPDM Ball

>>

Wholesale Small 10-120ml Oil/Ink Plastic (PET) Liquid Packaging Bottles

>>

Hot Sale Woodworking PCD Tip Saw Blade for Wood Plywood Laminated Panel MDF

>>

Casserole Lids for Chinese Granite Cookware Cooker Set Cover

>>

SIMCom SIM7000A LPWA Module, Cat-M/NB-IoT Module SIM7000

>>

100-2000kg/H Plastic PE PP Film Recycling Washing Line

>>

Bafang 48V 27inch 29 Inch 17ah 500W 750W Hidden Battery Pedelec Speed LCD Motor Wholesale Electric Mountain E Bike

>>

OEM Customized Metal Stamping Part/Stamped Part for Various Usage