|

US$12,000.00-18,000.00

|

1 Set

(MOQ)

|

Basic Info.

Plastic Type

Thermoplastic

Plasticizing Way

Screw Type

Clamping Way

Hydraulic & Mechanical

Computerized

Computerized

Certification

CE, ISO9001:2008, SGS

Keyword

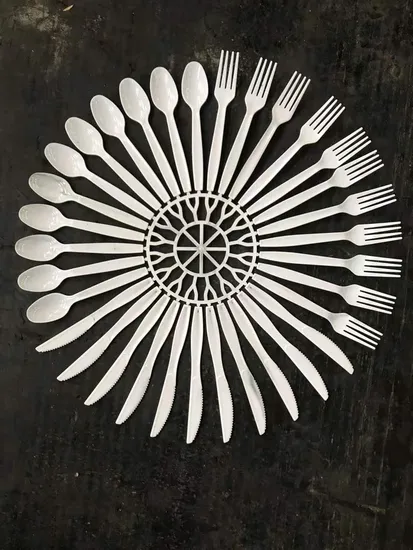

Plastic Spoon Knife Spoon Pallet Making Machine

Function

Multifunctional Plastic Products Making

Motor

Servo Energy Saving

Advantages

Energy Efficient,Long Service Life

Operation Language

Multilingual, You Can Choose

Experience

20 Years of Rich Experience

Quality

Professional Quality Control Team

After Sale

Product Lifetime Maintenance

Brand

Shenzhou,China Certified Brand

Service

One-Stop Complete Solution

Export Experience

More Than 15 Years

Transport Package

Standard Export Wooden Box

Specification

4.7*1.25*1.85m

Origin

Suzhou, Jiangsu, China

Production Capacity

50sets Per Month

Product Description

Product Description

Product Parameters

SZ-1300A INJECTION UNIT

|

ITEM

| UNIT

| VALUE

|

SCREW DIAMETER

| mm

| 35

| 40

| 45

|

SCREW L/D RATIO

| L/D

| 24

| 21

| 18.7

|

Theoretical Shot Volume

| cm^3

| 173

| 226

| 286

|

SHOW WEIGHT(PS)

| g

| 158

| 206

| 260

|

INJECTION PRESSURE

| Mpa

| 235

| 180

| 142

|

THEORETICAL INJECTION RATE(PS)

| g/s

| 110

| 143

| 181

|

PLASTICISING CAPACITY

| g/s

| 13.8

| 19.7

| 27.1

|

SCREW TORQUE

| N.m

| 740

|

MAX.SCREW ROTATE SPEED

| r/min

| 250

|

INJECTION STROKE

| mm

| 180

|

SZ-1300A CLAMPING UNIT

|

ITEM

| UNIT

| VALUE

|

MAX.CLAMPING FORCE

| KN

| 1300

|

MAX.OPENING STROKE

| mm

| 400

|

SPACE BETWEEN TIE BARS

| mm

| 420*420

|

MOULD HEIGHT

| mm

| 160-440

|

MAX.DAYLIGHT

| mm

| 840

|

EJECTOR FORCE

| KN

| 31.4

|

EJECTOR STROKE

| mm

| 100

|

EJECTOR QUANTITY

|

| 5

|

SZ-1300A OTHER

|

ITEM

| UNIT

| VALUE

|

PUMP MOTOR POWER

| kw

| 13

|

PUMP PRESSURE

| Mpa

| 16

|

HEATING POWER

| kw

| 9.2

|

HEATING ZONE

|

| 4

|

SIZE

| m

| 4.7*1.25*1.85

|

NET WEIGHT

| t

| 4.3

|

OIL TANK CAPACITY

| L

| 360

|

INTERNATIONAL DESIGNATION

|

| 1300-410

|

Innovative 5-point toggle mechanism ensures a stable movement curve with minimal shock and smooth operation. Our robust superior mould platen maintains shape integrity even under high-pressure clamping for consistent performance.

Crafted from premium alloy, the hard chrome-plated tie bars offer exceptional tensile strength and longevity.

Durable, wear-resistant guides enhance the smooth movement of the platen for precision and reliability.

Advanced transducer technology controls the clamping stroke for precise operational accuracy.

Multistage control system optimizes speed and pressure during both clamping and opening phases.

Ejection device features versatile dwelling, single and multiple vibrations functions, enhancing operational flexibility.

Low pressure mould protection guarantees the safety and longevity of the moulds, safeguarding your investment.

Hydraulic mould height adjustment offers both rough and fine tuning for precision and ease of use.

Dual safety interlock system combines mechanical and electrical features for enhanced operator safety.

Automatic centralized lubrication system features a remote pressure detector for seamless maintenance.

Proportional pressure and flow control with fine adjustments ensures high precision and efficiency. Our expertly designed manifold is compact, logical, and boasts a rapid response time.

Equipped with globally-renowned imported hydraulic valves for unmatched reliability.

High-quality imported hydraulic sealing rings ensure tight seals and prevent leaks.

Utilizes cutting-edge imported technology for hydraulic hose and fittings, guaranteeing durability.

Our hydraulic system is engineered for low noise, ensuring a quieter working environment.

Precision oil filter and oil cooler maintain optimal conditions for system performance.

Nitrided screw and barrel are designed for extended service life and superior performance. The smelted screw features a large L/D ratio for excellent plasticizing and color-fixing capabilities.

Compact double injection cylinder ensures balanced performance and structural efficiency.

State-of-the-art transducer controls the injection stroke with pinpoint accuracy.

Adjustable speed of the low-speed, high-torque hydraulic motor for customizable performance.

Control systems manage screw back pressure and nozzle leakage, with a movable hopper for easy material removal.

Flexible injection-carriage system supports slacking, re-feeding, and fixed-feeding operations.

Injection speed and pressure can be precisely controlled by either time or position settings.

Reverse device included for effortless cleaning and maintenance.

Why Choose Us

1. With 20 years of experience in injection molding machine and mold manufacturing, we guarantee exceptional quality and honest management.

2. We are at the forefront of continuous technological innovation, ensuring optimized product structures and extended service life.

3. Enjoy lifetime maintenance for your products, complemented by our 24-hour after-sales service.

4. We use only the main components from world-renowned brands to assure top-notch quality.

5. Our dedicated quality control department ensures all products meet the highest standards.

6. Benefit from ex-factory pricing for cost-effective solutions.

Company Profile

SHENZHOU - Your trusted partner in plastic processing solutions.Our company specializes in manufacturing injection molding machines, blow molding machines, main blowers, molds, and computer embroidery machines. Strategically located in Zhangjiagang City, Xizhang Town, near Yanjiang Expressway and 204 National Road, we boast convenient access to major cities like Shanghai, Nanjing, Suzhou, Wuxi, and Nantong.

With years of expertise in injection molding machine manufacturing, we pride ourselves on high-standard design and precision processing. By integrating imported, renowned hydraulic, electrical, and sealing components, we offer the SZ series of automatic computer injection molding machines and supporting peripherals, characterized by superior quality, stability, and excellent price-performance ratio, effectively addressing customer needs and interests.

Packing & Delivery

To ensure the utmost satisfaction and durability of our products, we meticulously apply premium lubricating oil and a protective anti-rust agent before shipment. Rest assured, ample spare parts are prepared, and comprehensive checks confirm secure fastening. Every detail is our priority, striving to deliver an exceptional experience to you.

FAQ

1.Q: Are you a factory or trading company?

A: We offer a seamless Industry and Trade Integration, delivering factory-direct pricing with unparalleled quality. We warmly invite you to visit us and experience our excellence firsthand!

2.Q: How does your factory handle quality control?

A: At our company, 'Quality is Priority.' We focus on superior quality management from inception to completion, supported by a dedicated quality control department ensuring impeccable standards throughout.

3.Q: What are your normal lead times?

A: Our standard lead times range from 25-35 days post-order receipt. For urgent needs, our specialized venues and expert engineers efficiently manage expedited orders, enabling shipment in as little as 2 weeks.

4.Q: How do you determine your pricing?

A: We meticulously calculate costs to offer you the most competitive pricing while guaranteeing superior product quality and exceptional after-sales service. Loyal customers benefit from exclusive price advantages.

5.Q: How does your machine stand out from others?

A: Our machines boast an optimized layout for seamless operation and enhanced longevity. Each component is distinctively marked for effortless part replacement and ease of use, ensuring a superior user experience.

6.Q: Where is your factory located, and how can I visit?

A: Our factory is situated at the heart of Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City, China. We extend a warm welcome to all our domestic and international clients to visit and explore our facilities.

We welcome you to send samples, allowing us to customize high-quality machines tailored to your needs! Sending our best wishes your way!

>>

T6/19mm Amalgam UV Lamp Germicidal UV Lamp Water Treatment UV lamp TROJAN 79447 �80W�W�W�W�W

>>

Zy988-4 Zoyer Ex Series 4-Thread Super High Speed Overlock Sewing Machine

>>

Duyue Qt4-20 Hydraulic Pressure Building Material Brick Machinery

>>

High pressure dairy milk pasteurizer milk homogenization machine

>>

China silver fir battery 2VEG500 price discount

>>

55 Inch Shopping Mall Floor Standing Vertical TV Touch Screen Kiosk 4K Indoor Advertising Player Display Screen HD LCD LED Digital Signage

>>

SW-VJ 200 Classic Satin Letterman Bomber jacket for men Custom American Street Wear Jackets Embroidered Patch Work

>>

AAA Walnut Kernel in Halves

>>

D Shaped Marine Rubber Fenders for Dock Use

>>

Hot Selling Wholesale OEM non- retractable luggage suv car trunk shade cargo cover for Honda Crosstour rear shield parcel shelf

>>

Hot Sale Wall Mounted Bathroom Shower Head Set

>>

Waterproof Greaseproof Food Waste 100% Biodegradable Brown Kraft Paper PLA Film Kitchen Bags Without Handles

>>

Water Lifebuoy Water Emergency Supplies

>>

Air Spring Air Bag Air Suspension 2e200-19p01 for Tata

>>

Synchronous Torsion Bar Press Brake 100tons 4000mm Sheet Metal Bending Machine for Sale

>>

SHENGKEG Hot Sell Watch for Women K0106L Minimalisim Design Black Watches Wrist Ladies Glitter Handwatch

>>

New body kits for BMW X6 E71 X6M HM-M2 style wide body kit middle muffler X6 new body kit manufacturer 2008-2013 Year

>>

Roller Shutter Strip Making Machine/ Roll-up Door Cold Roll Forming Machine

>>

Autoart 1/18 Pagani Huaya Alloy Sports Car Model

>>

Low Cost Household Wall Floor Renovation Waterproof Vinyl Peel and Stick Tiles