|

US$6,800.00-25,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Automatic Grade

Both Manual and Automatic

Mold Max.Installation Size

850X500 mm ( or Customized )

Rated Power of Hydraulic Station

5.5-7.5kw

Name

Aluminum Gravity Casting Machine

Application

All Manufacturers of Metal Parts

Usage

Cars and Motorcycle Accessories

Casting Machine Type

Gravity Casting Machine

Transport Package

Wooden Case

Specification

900x500 mm ( or customized )

Production Capacity

200set /One Year

Product Description

Company Profile

We are automatic equipment and automatic production line manufacturer in China. Mainly for metal and foam products' equipment . Such as aluminum or brass gravity casting production line ,aluminum or brass gravity casting unit, PU foam products production line , gravity casting machine, high pressure PU foam machine ...., all our automatic production line with robot pouring , SIEMENS PLC programming, robot on line tracking pouring. We have our own patent and software copy rights. we have more than 6 years experience, with experienced team . Our most customers are China mid or big companys , we have our own export rights. With high quality and best price products, we belive we can have a good cooperation.

Product Description

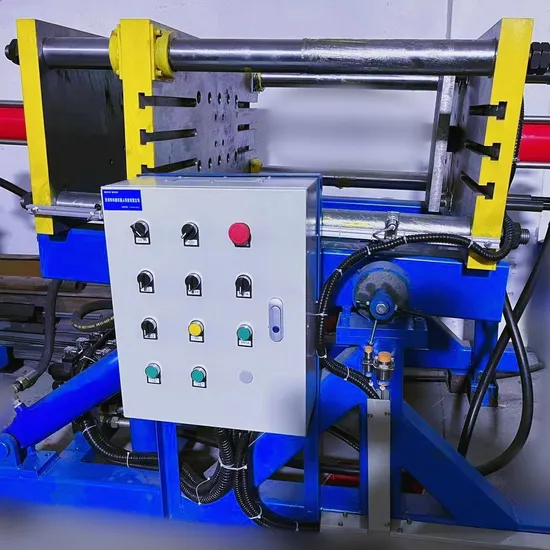

0-90°tilting gravity casting machine, it uses for pouring aluminum ,copper or brass products for auto parts or others foundry company.. Below are our gravity casting machine photos:

Factory gravity casting machines :

We use YUKEN brand solenoid valve and customized big brand oil cylinder for gravity casting machine , high quality oil tube. Make sure the casting machine quality is high for our customer. Product Parameters

| Parameter / Model | JJ-5040 | JJ-6050 | JJ-8060 | JJ-1080 | JJ-1210 |

| Mold plate Max.size | 700*500mm | 800*600mm | 1100*700mm | 1300*900mm | 1500*1000mm |

| Mold Max.installation size | 510*400mm | 610*500mm | 810*600mm | 910*800mm | 1200*800mm |

| Mold plate thickness | 50mm | 70mm | 85mm | 115mm | 130mm |

| Open and close main cylinder diameter/stroke | Φ80*700mm (Double cylinder) | Φ80*700mm (Double cylinder) | Φ80*600mm (Double cylinder) | Φ100*700mm (Double cylinder) | Φ125*900mm (Double cylinder) |

| Core jacking cylinder diameter/stroke | Φ63*50mm | Φ63*50mm | Φ63*50mm | Φ63*50mm | Φ63*50mm |

| The Max. distance between two mold plate | 900mm | 900mm | 900mm | 1000mm | 1200mm |

| The Min. distance between two mold plate | 200mm | 200mm | 300mm | 300mm | 300mm |

| Tilt angle | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° |

| Tilt speed | Manually adjustable | Manually adjustable | Manually adjustable | Manually adjustable | Manually adjustable |

| Equipped with two channels of temperature control instrument | Digital display | Digital display | Digital display | Digital display | Digital display |

| Equipped with a two - way cold air system | solenoid valve | solenoid valve | solenoid valve | solenoid valve | solenoid valve |

| Power | AC 380V 50/60Hz | AC 380V 50/60Hz | AC 380V 50Hz | AC 380V 50/60Hz | AC 380V 50/60Hz |

| Rated power of hydraulic station | 5.5KW | 5.5KW | 7.5KW | 11KW | 15KW |

| Hydraulic system pressure/flow ratingL/min | 15Mpa/21 | 15Mpa/21 | 17Mpa/27 | 19Mpa/47 | 21Mpa/53 |

Our gravity casting machine have both manual and automatic function.

Our gravity casting machines are accept customized .

Our gravity casting machine mainly use in aluminum / copper casting factory. such as auto parts. It is also can produce casting parts with sand core.

Our Advantages

We are also a casting automatic production line manufacturer, we have gravity casting unit and turntable gravity casting production line , all use robobt to pouring ! It is easy to operate and save labour. increasingly increase prodcution ! and safe!

1.Gravity casting automatic production line

Advantage :

-14 sets gravity casting machines, large production for foundry company.

-Every 5-7minutes one circle pouring (according to product cooling time to set ),

- One robot pouring , continous pouring( can be 24 hours working )

- One 11KW hydraulic station ( power saving ) for full production line

- rotary round turntable , diameter: 10M

- Just need 1-2 workers to operate( save labour)

- It also can come true robot pick up products, can according to customers'

need to make( come true unmanned automation )

2.RobotIc gravity casting Unit

Advantage :

- Four or six gravity casting machines for one unit

- Every 5 minutes one circle pouring (according to product cooling time to set ),

- One robot pouring , continous pouring( can be 24 hours working )

- One 5.5KW hydraulic station ( power saving ) for gravity casting unit

- Just need 1-2 workers to operate( save labour)

- can pouring product with sand core,

We have our own robot pouring system, which we have gotten the patent and

software copyrights Certification.

Gravity casting automatic production line Photos :

Robotic gravity casting Unit photo:

Certifications

Our company Gravity casting automatic production line and gravity casting unit with our own patent and software copyrights certification:

Packaging & Shipping

After Sales Service

One year warranty , We provide on line or video or customer's factory service.

Installation Instructions

For gravity casting production line, once the equipment reach customer's factory, we will arrange the workers to customer's company to install,test ,training .

Lead time : 15-30 days after receive the deposite by T/T ( for single gravity casting machine) , 90days for production line .

Payment term : 50% deposite by T/T, 50% paid before delivery

Installation :

For single gravity casting machine, we can teach how to install it by video or phone.

Contact: linda

>>

Z Purlinpre-Punching and Pre-Cutting Purline Roll Forming Machine

>>

Wedding Events Photobooth Portable Selfie Magic Mirror Photo Booth Touch Screen Machine

>>

TGGS75-400HDPE Plastic Geogrid Room Large Government Project Parking Lot Roadbed Reinforcement

>>

New Structure POY Paper Tube Packaging and Stacking Machine for Chemical Fiber

>>

Sleeper White Noise Broadcast Speaker Computer Home Bedside Desktop Multifunctional FM Wireless Bluetooth Audio

>>

Factory Sale 13000lbs 12V/24V Electric Winch for SUV Car Wire Rope Nylon Rope Car Towing Winch

>>

Wholesale Fabric Textile Synthetic PU Leather PVC Rexine Artificial Microfiber Shoe Materials

>>

OGM series Meter Gear Liquid Flowmeter Oval Flow Meter Japan Digital Diesel Fuel Flow Meter

>>

2024 Environmentally Hotsale Luxury Walking Bike Stroll Bicycle Electric Car Treadmill

>>

Carbon fiber strips bars 5x20mm Carbon Fiber Flat Strips Fiberglass Strips

>>

Mellanox MCX556A-Ecat Connectx-5 Vpi EDR 100GB/S Infiniband Adapter Card

>>

Custom Stainless Steel Valve Body Valve Spare Parts Lost Wax Casting Parts Investment Casting

>>

Japanese Natural Organic Reusable Eco Friendly Biodegradable Bento Food Containers Lunch Box Bamboo

>>

Hot Sale Body Kits For Audi A5 2017 2018 2019 Upgrade RS5 Front Bumper Car Grille Side Skirt Rear Bumper Diffuser Exhaust Pipe

>>

waterproof canvas hobo bag with waterproof fabric

>>

Liugong 6 Ton Mini Excavator 906f Crawler Digger with Yanmar Engine

>>

Desktop Alarm Clock Docking Station Speaker USB Charging Port

>>

Radiator S1609-04601 S1609-04602 S1609-04603 S1609-04604 S1609-05560 S1609-05650 for Hino RANGER FD1J FD2J FE1J GD1J FF1J J08C

>>

Warranty Void Hologram Sticker with Scratch QR

>>

Polyester Fabric Camouflage Coated Waterproof Oxford Fabric for Bags Luggage Outdoor Tent