|

US$100,000.00-700,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Material Processed

Plastic Bottle

Computerized

Computerized

Certification

ISO9001:2008, CE

Processing Capacity

15~20 Tons Per Furnace

Working Pressure

Normal Pressure

Working Temperature

- 20 ~ 400 ºC

Finished Product

Acrylic Plastic Oil

Transport Package

Standard Shipping Package

Specification

2600mm*7700mm

Origin

Shangqiu, Henan Province, China

Production Capacity

500pieces/Year

Packaging & Delivery

Package Size

8000.00cm * 2600.00cm * 2600.00cm

Package Gross Weight

30000.000kg

Product Description

1.Working Theory of Acrylic Thermal Cracking

Specification

| No. | Name | Parameter |

| 1 | The Raw Material | solid waste/ waste rubber/ waste plastics/ waste tyre |

| 2 | Total Capacity | 5t/day, 10t/day, 12t/day, 50t/day |

| 3 | The size of reactor | 2.6m*6.6m, 2.6m*7.7m, 2.6m*8.8m, customized |

| 4 | Average oil productivity | tyre:40%-50%,plastic:60%-70% |

| 5 | Average carbon productivity | 30%-35% |

| 6 | Average steel productivity | 10%-15% |

| 7 | Average waste-gas productivity | 5% |

| 8 | Pyrolysis time | 8h |

| 9 | Discharge time | 3h |

| 10 | Feeding timme | 1h |

Acrylic, also known as PMMA or organic glass, originated from acrylic (acrylic plastic) in English, and the chemical name is polymethylene acrylic nail vinegar. After the device is treated, Acrylic can be resource and reuse, and during the processing process, the waste acrylic is used to refine the solid acrylic into liquid acrylic oil from high temperature anaerobic cracking. The oil output rate is about 95%. This coarse oil cannot be used directly for acrylic manufacturing. It must be refined and purified before it can be used for new acrylic manufacturing.

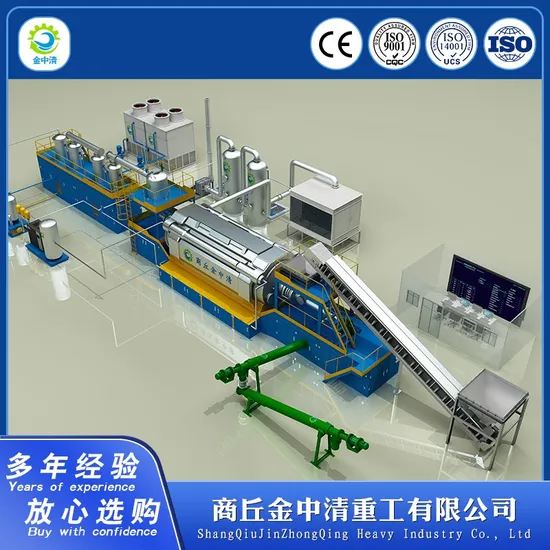

2.Main Parts

2.1 Reactor: to crack fuel oil and carbon black from waste plastic, tires, urban waste, etc.

2.2 Heating system: to supply energy for whole system operation.

2.3 Condensing system: to liquefy the gas oil into liquid oil with cycle water and store the fuel oil into the tempory tanks

2.4 Carbon black discharging and collecting system

3. Basic Operation

4. Our Advantages

1. The pyrolysis furnace body adopts the structure of heat storage body, which fully recycles the waste heat. That can not only extend the service life of the main furnace, but also save fuel, leading to further savings in production costs.

2. The furnace bladder adopts specially high-temperature resistant quasi-brand boiler steel, and the service life can reach 8 years.

3. The equipment is installed with self-developed infrared anti-blocking early warning dredging device, which is the exclusive device developed by our company. It can figure out pipeline blockage phenomenon in the production process, sound an early warning and automatically solve the problem to ensure that the main furnace will not have safety problems due to pipeline blockage during the production process.

4. The slag discharge system adopts a double-cycle structure, which controls the slag discharge time within about 40 minutes. The system can discharge slag quickly and cleanly.

5. Self-developed chemical accelerator of our company increases the oil yield by 3%-8%.

6. Adopting a new exhaust gas purification system can make the gas emitted after purification meet the relevant national emission standards.

7. Excess combustible gas is dehydrated and desulfurized by the purification system and then stored in a gas storage tank after compression by a special gas compressor, which can be used for heating later, and can also be supplied to gas generators for use or sale.

8. The main furnace uses more convection vents and rapid cooling devices, so that its temperature drops below 100 degrees within three hours.

5. Our Services

5.1 Pre-sales Service:

The wide product range enables us to provide our customers with machines or complete processing plants.

Based on our customers' request and budget, our experts make efficient and reliable solutions.

Following customers' order we produce strictly. What's more, before placing the order every customer has the chance to visit working machines or complete plant in the site.

5.2 After-sales Service:

1.Quality warranty period: One year warranty for the reactor ,and lifetime maintenance for complete set of machines. pay the double air tickets, accommodation and food.

2.According to the requirement of the buyer, our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's workers on operation, maintenance, etc.

3.Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.

4. For the damage caused by the users, our company provides the parts and accessories with cost price.

5. Our factory supplies the wearing parts with the cost price to clients.

6.Company Introduction

Shangqiu Zhongqing Environmental Protection Science and Technology Co., Ltd. is a collection of research and development, design, development, manufacturing, installation and debugging, operation and maintenance, after-sales service as an environmental protection equipment and accessories integrated manufacturing factory.

7.Successful Case

>>

Wheat Starch spin flash dryer

>>

RJ45 Straight Head up Bend

>>

Modern whole wheat flour bread grinding machine

>>

Liquid Ring Type Vacuum Pumps (2BE3) / Water Ring Vacuum Pump

>>

Carbon Steel Pumping Mould OEM Auto Parts Tool and Die

>>

Promotional Passenger Car Tyre/PCR/LTR/Commercial/ Van Tyres (185R14C 195R14C 205/65R15C)

>>

Super Chess Edition Board Game Action Figure Miniature

>>

Wholesale White Tulle Lace Fabric Embroidery Floral Lace 3D Guipure Lace Fabric

>>

Orthopedic Lumbar Support Stretch Magic Massager Lower Back Stretcher

>>

7KG Washing Machine Factory Domestic Twin Tub Clothes Washing Machine Sale

>>

Tractor Pto Mounted Diesel Engine Peanut Picker

>>

Construction Machinery 2.5m3 Self Loading Concrete Mixer Hy250

>>

Efficient Shrink Wrap Machine for Retail Packaging

>>

PA Speakers Line Array (Aero 50)

>>

Factory Price Farm Machinery Floating Fish Feed Pellet Making Machine for Sale

>>

Used Caterpillar 313D2 Excavator Used Cat 313 Hydraulic Excavator

>>

10HP Diesel Cultivators Power Tiller

>>

Wholesale Good Feedback portable shower curtain rod

>>

High Precision Quality Metal Grinder Myk4100 Universal Hydraulic CNC Grinding Machine

>>

Light-blocking chemical reagent cabinet,chemical lab reagent storage cabinet