Basic Info.

Application

Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry, Aerospace

Cooling System

Water Cooling

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Gantry Type

Laser Classification

Solid Laser

Laser Technology

Laser Control Fault Cutting

Power

1500W, 2000W, 3000W, 6000W

Cutting Thickness

0.5mm-30mm

Appearance Material

Metal Shell Metarial

Transport Package

Warpping Film and Plastic

Specification

8325*1400*2400

Production Capacity

5000pieces/Year

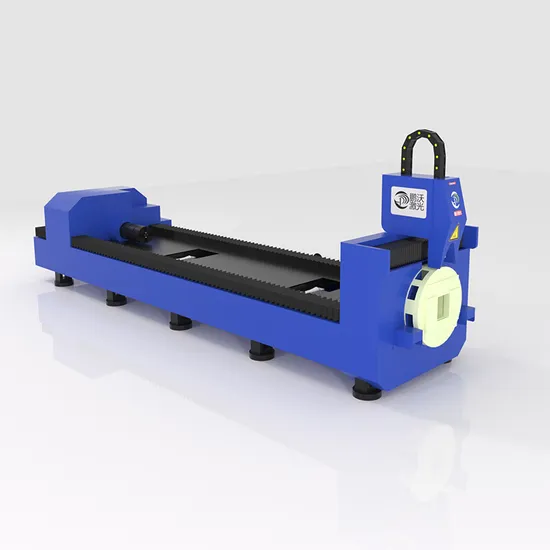

Product Description

Product Description

Product Features

Outstanding Features of Pipe Cutting Machine

1. Immerse yourself in a world of seamless automation with our machine's state-of-the-art capability for automatic feeding, lightning-fast cutting, and the ultra-efficient collection of both finished products and waste materials.

2. Masterfully crafted to accommodate round, square, and elliptical tubes, our machine shines in the artistry of intersecting line creation and precision cuts at any angle, elevating versatility and functionality to unprecedented heights.

3. Harness the power of our machine's rapid automatic cutting and forming capabilities, offering unmatched cutting efficiency and precision that caters to the most exacting standards of accuracy and excellence.

4. Revel in the superior quality of our incisions; each cut is flat, smooth, and free of burrs and slag, boasting impressively low surface roughness to ensure a pristine, flawless finish every single time.

5. Thanks to the intensely focused laser beam energy on a minuscule area, the heat-affected zone is minimized, ensuring exceptionally low local deformation post-cutting and negating the need for any subsequent corrections.

Product Parameters

| Name&Model | Laser Cutting Machine T1260F-A/T1660F-A/T2360F-A/T3560F-A |

| Working Area | φ120mm*6000mmφ160mm*6000mmφ230mm*6000mmφ350mm*6000mm |

| Laser Power | 1500W/2000W/3000W/6000W/12000W/20000W//30000W/50000W |

| Machine Structure | Stable & strong welded bed with high temperature annealing |

| Beam | Aviation aluminum/Integrated cast aluminum beam |

| MAX Speed | 80m/min |

| Applicable Material | Carbon Steel Stainless Steel Etc( Metal Laser Cutting Machine ) |

| Laser Source Brand | MAX/RAYCUS |

| Key Selling Points | Automatic |

| Warranty | 2 years |

| Condition | New |

| Max acceleration | 0.8G |

| Position Accuracy | ±0.03mm |

| Repositioning Accuracy | ±0.02mm |

| Computer | Industry Computer |

| Transfer method | Gear rack dual drive |

| Working Voltage | 380V,3phase,50hz/60hz(customized) |

| Dimension | 8325*1400*2300/8325*1400*2400/8325*1400*2500/8325*1400*3100 |

| Graphic Format Supported | AI, PLT, DXF, BMP, DST DWG, LAS, DXP |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Applicable Material | Metal Steel Carbon Copper |

Detailed Photos

Our pipe cutting machines are the epitome of precision and innovation, boasting cutting-edge laser technologies that elevate your cutting processes to new heights. Designed for seamlessly smooth operation, this machine offers unparalleled accuracy, effortlessly adapting to pipes of varying specifications and materials with impressive ease. Revel in the machine's versatility as it expertly performs bevel cuts, groove cuts, and more, catering to the diverse requirements of multiple industries. This remarkable cutting machine is the ideal partner to enhance your expertise and significantly boost your production capabilities. We extend a warm invitation to consult with us and discover how our pioneering solutions can be tailored to fulfill your exact needs!

Company Profile

Nestled in the bustling and dynamic city of Dezhou, Shandong Province, Shandong Pengwo Laser Technology Co., Ltd. embarked on its transformative journey in 2005. This visionary enterprise shines as a beacon of innovation and excellence, devoted to pioneering research, groundbreaking development, and the meticulous crafting of cutting-edge laser processing machinery. Recognized as a trusted purveyor of intelligent manufacturing solutions, Shandong Pengwo Laser Technology has solidified its prestigious standing as a leading force in China's thriving laser application equipment industry. Commanding an expansive footprint exceeding 80,000 square meters, the company operates from two major production hubs located in Dezhou Tianqu New District and Pingyuan County. These facilities pulsate as the vibrant core of its operations, where revolutionary advancements in medium and high-power laser cutting, welding, and cladding equipment are brought to life. With an unparalleled commitment to automation, customization, and adaptive R&D and manufacturing expertise, Shandong Pengwo Laser Technology has garnered the trust of a diverse and distinguished clientele. From automotive components to kitchen and bathroom fixtures, electronics, smart home technology, and beyond, their innovative products power precision manufacturing across a wide array of industries. Their impressive reach spans engineering machinery, building templates, prefabricated structures, power transmission towers, and indispensable petrochemical machinery. As trailblazers, they continually expand their horizons into nascent fields such as new energy vehicles, aerospace innovation, and high-end agricultural machinery, driving global advancements and propelling innovation to unprecedented heights.

Certifications

In our relentless pursuit of excellence, Shandong Pengwo Laser Technology Co., Ltd. ensures our fiber laser cutting machines are crafted using the finest raw materials and components. We implement rigorous quality control measures, steadfastly adhering to international standards. Our dedication to perfection is reflected in obtaining all necessary qualifications, which shape and realize our ambitious quality policies and goals.

Quality system: We are immensely proud to have achieved the ISO9001:2005 international quality system certification. This prestigious accolade is a testament to our unwavering commitment to upholding superior quality in every facet of our operations.

Quality policy: Our guiding principles ensure success through insightful management. We maintain enduring quality as the cornerstone of our survival, deliver exceptional service to secure valuable returns, and continuously innovate to drive sustained growth.

Quality goals: Our unwavering aim is to achieve nothing short of 100% customer satisfaction. We boast an extraordinary product installation success rate of over 99.5%, complemented by a perfect 100% product unpacking qualification rate. These metrics underscore our relentless pursuit of excellence.

After Sales Service

Installation Training: Tailored Options to Suit Your Needs

A. Experience a seamless start with our comprehensive training resources, meticulously crafted to ensure your success. We provide an array of detailed installation, operation, maintenance, and troubleshooting videos, accompanied by intuitive manuals, all available in English. Should you have any inquiries related to installation or operations, our team of seasoned technical experts is just an email, fax, phone call, Messenger, or WhatsApp message away, ready to assist you.

B. Immerse yourself in hands-on learning by visiting our state-of-the-art facilities in China, where cutting-edge technology meets expert instruction. We are committed to making your training experience as comfortable and enriching as possible, offering complimentary accommodation throughout your stay.

C. Benefit from our robust after-sales service team based in China, equipped with proficient engineers who are fluent in English and prepared to resolve any operational issues that may arise. We are dedicated to ensuring smooth operations and can arrange flights for on-site support to assist you swiftly and effectively.

Training Duration: Optimize your learning potential with our intensive training program, recommended to span 3-7 working days for maximum proficiency and skill acquisition.

For a truly personalized experience, we offer complimentary installation, commissioning, and training directly at your worksite. While we are delighted to cover these services, please note that as our esteemed customer, you will be responsible for the supplier's travel-related expenses, including airfare, meals, accommodation, local transportation, as well as any translation and communication costs incurred at your premises, all based on actual documented expenses.

FAQ

Q1. When was your factory established?We have been specialized in the R&D, manufacturing and intelligent manufacturing solutions of laser processing equipment since 2005, mainly focusing on laser processing equipment such as fiber laser cutting, laser welding equipment, laser cladding equipment, etc.

Q2. What should I do if there is a problem with this machine during the warranty period?

The quality assurance period is 12 months from the date the goods arrive at the destination port. Except for man-made damage, we are responsible for providing accessories free of charge during the warranty period. After the quality assurance period, if you need to repair or replace parts, you must pay.

Q3. How to install and use?

We will provide training videos and English user manuals for installation, operation, maintenance and troubleshooting for the machine. When you encounter installation, use or adjustment problems, we will provide technical guidance by email, fax, telephone/Messenger/WhatsApp, etc.

Q4. What should I do if there is an after-sales problem?

You can directly describe your problem to the after-sales staff. China's strong after-sales service team. Our engineers (employees) can communicate and solve problems in English, and can be arranged once a day per person when you need it. If I need to go to your place to help, I will quickly arrange to go there and quickly fly to help you.

Q5. How about wholesale price?

If you are a wholesaler, distributor or agent, please contact us to get wholesale price.

>>

Automatic Boot and Vamp Shoe Shaping Machine Footwear Machine

>>

Multifunction Organic Fertilizer Compost Making Fermentation Tank for Agricultural Waste

>>

Rare Earth Permanent N35/N38/N40/N42/N45/N48/N50/N52/N55 Neodymium Sintered Block Dics Cylinder Arc NdFeB Magnet

>>

High Quality Car Mats Anti-Slip Car Floor Mats 3D Rubber Car Accessories Mat for RAV4 2014

>>

300ml Pet Can Watermelon Juice Drink Soda Sparkling Water

>>

Efficient and Energy-Saving Blow Molding Machine Large-Scale Storage Type Fully Automatic Plastic Bucket Blow Molding Machine

>>

Custom Blue and White Motorcycle Front Fork Tube Front Shock Absorber

>>

Hot Sale Inflatable Air Roll 200m Packaging Material Air Foam Wrap Roll Air Pouch Bubble Cushion/Bag

>>

Potato Flakes Food Grade-Feed Grade, 0.2mm-4mm

>>

Biodegradable Recycled Customized Stand up Kraft Paper Bag with Translucent Window

>>

Laboratory Roving Machine

>>

Versatile CNC Beam Drilling Machine for Steel Plates

>>

High Quality Reed Wire for All Kinds of Textile Looms

>>

Best Selling Essential Classic 9 Inch Custom Carbon Steel Nonstick Pizza Baking Pan

>>

One-Stop LED Driver Inverter PCB Assembly Electrical-Electronics PCB LED Module

>>

SUS 304 Fully Automatic Vertical Powder Packing Machine 1kg 2kg 5kg Cassava Wheat Flour Packaging Machine

>>

Alimoto Rugged Phone Keyless Theft Proof and Water Proof 4G Smart Phone

>>

Bone and Lung CT Scanner, 16 Slice CT, 32 Slice CT, 64 Slice CT scan

>>

3/2-5/2 Convertible 4m310 Namur Pneumatic Solenoid Valve

>>

Cashino CSN-58II 58mm Thermal Receipt Printer POS Printer for Retail Store