|

US$0.50-8.80

|

1 Piece

(MOQ)

|

Basic Info.

Material

Phenolic Paper Laminate

Application

Medical Instruments

Flame Retardant Properties

V0

Processing Technology

Electrolytic Foil

Production Process

Semi-Additive Process

Insulation Materials

Metal Composite Materials

Test

Flying Probe & Fixture

Min.Line Width/Space

4/4mil

Min. Finished Hole Size

4mm

Certification

RoHS, CCC, ISO, EPA

Transport Package

Bubble Pack+Aluminum Foil Pack

Production Capacity

100000 S. Q. M/Month

Packaging & Delivery

Package Size

25.00cm * 25.00cm * 0.16cm

Package Gross Weight

2.500kg

Product Description

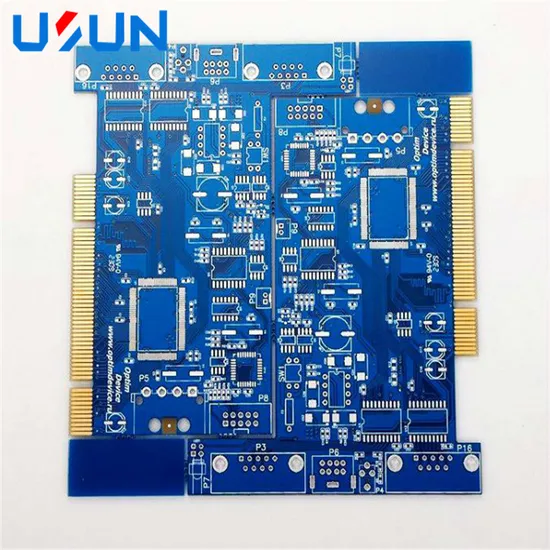

Detailed Photos

In strict accordance with the drilling process PIN - drilling - check control hole quality;

Exquisite copper sinking process to produce high quality printed circuit boards to meet various application requirements.

PCB copper sinking process beyond customer requirements.

Rigid PCB-Technical capacity

| Item | Mass Producation | Small Batch Producation |

| Rigid Layer Counts | 1-36 | 38-64 |

| Flex Layer Counts | 2-6 | 8-10 |

| Rigid Flex Layer Counts | 4 - 14 | 16 - 20 |

| Standard Features |

| Max. board size (mm) | 580*620 | 1200*600 |

| Min. board size(mm) | 10*10 | 5*10 |

| Board thickness (mm) | 0.2~8mm | 0.2~8mm |

| Min. Line width/space (mil) | 3/3mil | 2.5/2.5mil |

| Outer Layer copper thickness (OZ) | 0.5 OZ-7OZ | 15 OZ |

| Inner layer copper thickness | 1OZ-7OZ | 12 OZ |

| Solder Mask color | Green, Blue, white, Black, Red, Yellow and so on |

| Carbon Ink Thickness(mil) | 0.3mil | 0.3mil |

| Impedance control tolerance | <=+/-10% | <=8+/-% |

| Min. SM bridge for green soldermask(MM) | 0.1 | 0.076 |

| Min. SM bridge for black soldermask(MM) | 0.125 | 0.1 |

| Tolerance of dimension size (MM) | <=+/-0.13 | +/-0.1 |

| Tolerance of board thickness (MM) | >=1.0 +/-10% | +/- 8% |

| < 1.0 +/-0.1 | +/- 8% |

| Tolerance of finished NPTH hole size(MM) | +/-0.05 | +/-0.05 |

| Tolerance of finished PTH hole size(MM) | +/-0.076 | +/-0.05 |

| Non-Conductive Via Fill (VIP) | Y | Y |

| Backdrilling | Y | Y |

| Hybrids & Mixed Dielectrics | Y | Y |

| HDI Features |

| Minimum Microvia Hole Size | 100μm [0.004"] | 75μm [0.003"] |

| Capture Pad Size | 0.25mm [0.010"] | 0.20mm [0.008"] |

| Maximum Aspect Ratio | 0.7:1 | 1:1 |

| Copper Filled Microvias | Y | Y |

| Stacked Microvias | Y | Y |

| Maximum No. of Buildup Layers | 3+N+3 | 5+N+5 |

Delivery Time

| Bare PCB |

| Layers | Quotation | Samples | 1-10 m² | 10-50 m² | ≥50 m² |

|

| 2 | 12H | 5days | 7days | 10days | 13days |

| 4 | 12H | 7days | 8days | 12days | 15days |

| 6 | 12H | 8days | 10days | 13days | 16days |

| 8 | 12H | 9days | 12days | 15days | 18days |

| 10 | 12H | 10days | 13days | 18days | 20days |

| ... | ... | ... | ... | ... | ... |

| PCB Assembly |

| Order Conditions | Standard Delivery Date | The Fastest Delivery Date |

| Prototype (<20 PCS) | 2-3 days | 12 hours |

| Small Volume (20-100 PCS) | 4-5 days | 24 hours |

| Medium Volume (100-1000 PCS) | 6-8 days | 36 hours |

| Mass Production (>1000 PCS) | Depends on BOM | Depends on BOM |

Application &Quality&Materials

Pre-Sale and After-Sale Service

√ 7*24 hours order service............

√ 7*24 hours delivery.....................√ 7*24 hours production run..........

√ 7*24 hours technical support......

√ 2 hours of complaint feedback...All the right materials for your next project.

RoHS Compliant

Turn to USUN Circuit to manufacture RoHS-compliant PCBs. We typically use SYST,Nanya ,Rogers products, as well as other options right for your project.

Materials include:

| FR4 Standard Tg | Shengyi, ITEQ, KB, Nanya |

| FR4 Mid Tg (Lead Free Compatible) | Shengyi S1000, ITEQ IT158 |

| FR4 High Tg(Lead Free Compatible) | Shengyi S1000-2, S1170,Isola 370HR,ITEQ IT180A, Panasonic R1755V |

| High Performance Low Loss FR4 | Isola FR408HR,Panasonic R5775 Megtron 6,ITEQ IT968,TUC TU-872 SLK |

| RF Materials | Rogers RO4350B, RO4003C ,RO3006 |

| Halogen Free | TU-883 , IT-988G SE |

| Rigid PI | Arlon 85N , Ventec VT-901 |

| Flexible Circuit Materials | Dupont, Panasonic, Taiflex, Shengyi |

| Hybrid laminating | Rogers/Taconic/Arlon/Nelco laminate with FR-4 material (including partial Ro4350B hybrid laminating with FR-4) |

| Thermal Clad (including Aluminum Bonding) |

Finishes include:

Immersion Tin (Sn)Immersion Sliver (Ag)Immersion Gold (Au)ENTEK/OSP (Organic Solder Preservative)LeadedLeadfree HALSoft bondable goldOur RoHS capabilities include:High Tg/High performance FR-4 materialHalogen-free solder maskLead-free surface finishes Contact Us for more information......

Company Profile

In 2023, USUN marks more than 16+ years of providing high-quality PCB & PCBA services to the electronics industry.

USUN has a professional team that provides a flexible one-stop solution for your PCBA project, including PCB design, component procurement, PCBA assembly, Box construction, and functional testing.

> 0-64 Layers Rigid PCB

> Metal core board

> HDI board

> RF board

> PCB Assembly

> Quick to respond Flexible Price with 24 hours

> Capacity of production: 100,000 m2 /Monthly;

> Capacity orders & Ship out: 10,000~15,000 part numbers/Monthly;

> Product Application Area:Car, Industrial Control, Power supply & Communication fields.

> System certification: ISO9001,ISO14001,IATF16949,ISO13485,QC080000,ISO9001,UL CERTUSUN employs current state-of-the-art circuit board production equipment, brings together experienced professionals for management, and introduces the latest technologies to ensure reliable and fast product delivery to customers.

Packaging & Shipping

FAQ

Q: What is needed for PCB/PCBA quotation?

A: For Bare PCB project, please provide Quantity, Gerber file and specification like material, surface finish treatment, copper thickness, board thickness, soldermask color and silkscreen color and other special

Q: Are my files safe?

A: Your files are held in complete safety and security. We protect the intellectual property for our customers in the whole process.. All documents from customers are never shared with any third parties. We are willing to sign NDA effect by customer side local law and promising to keep customers data in high confidential level.

Q: What is your minimum order quantity (MOQ)?

A:Our MOQ is 1 PCS, sample and mass production all can support.

Q: How to calculate the shipping cost?

A:The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need us to quote you the shipping cost.

Q: What is your testing policy and how you control the quality?

A:Regarding to PCB samples, usually tested by flying probe; for PCB Volume over 3 square meters, usually tested by Electrical fixture which is faster. As to PCBA production, there are automated optical inspection (AOI) for each batch, X-ray inspection for BGA parts, first article inspection(FAI) before mass production.

>>

Hengyuan Concrete Factory Diesel Concrete Mixer with Pump Mobile Concrete Mixer and Pump

>>

30% off Yourijiu Crystal Yellowish Waterproof Clear BOPP OPP Adhesive Packaging Economic Grade Customized Factory Price Easy Tear Tape

>>

Fiber Optic Straight Dental Low Speed Handpiece

>>

The Large Caliber Aluminum Easy Open Peel off Lid to Tear Cover for Food

>>

Multiple Colors Lamination Women′s Cellulose Handmade Sunglasses

>>

Advanced Full Servo Baby Pull-up Pants Manufacturing Machine

>>

Agricultural Machinery Durable Portable Hand Push Seeder Planter for Corn Maize Peanut Soybean 3.5-7.8cm Depth Plant Distance

>>

4.5 Cubic Meters Concrete Mixer Truck Cement Mixer

>>

Newest Hot Sale 0.5 Ton Mini Tracked Dump Truck Mountain Transport Pickup Truck

>>

Tensioner For FREIGHTLINER HD Parts No.3400885

>>

Dustproof For Restaurant Medical Surgical Use Mob Cap Bouffant Cap

>>

Home Theatre Portable Speaker Mx-X400

>>

Adult Scooter Kids High Speed New Cheap Motorcycle 3000W 4000W Electric Motorcycle

>>

Custom Two Shaft Waste Leather Granulator

>>

SHENGKEG Hot Watch Online K0075L Hunted Watch Online Reigio Lady Watches Wrist Chic Shiny Handwatch Saat

>>

Colorful Overflow Grating PP Slip-Resistant Swimming Pool Grating for Pool Accessory

>>

EN124 ductile cast iron surface box or valve box

>>

220kw AC Three Phase Ysd Landfill Generator Set Electric Water Cooled Free Energy Natural Gas Generator with Good Service

>>

K20NM55/K20DM55 sunnen CBN honing Stones for K20 honing mandrel

>>

Multifunction CO2 Laser Cutting Engraving Machine Laser Cutter 9060 Plywood/Acrylic/Leather/PVC/Fabric/Rubber