Basic Info.

Type

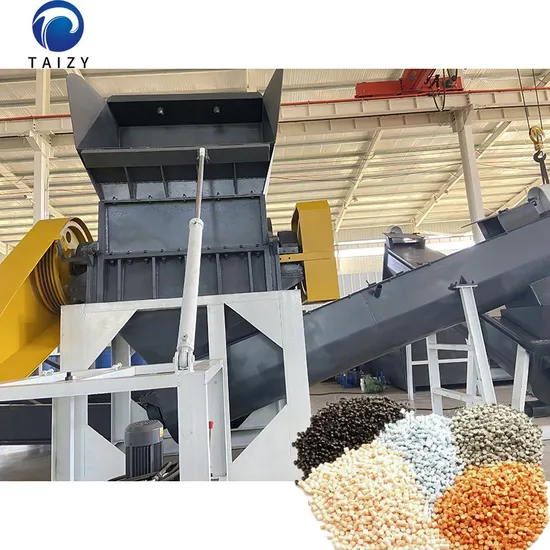

Hard Plastic Crusher

Knife Classification

Other

Computerized

Non-Computerized

Color

Customize as Client′s Request

Transport Package

Wooden Case

Production Capacity

15sets/Month

Product Description

Plastic pellet cutting plastic extruder machine line for soft and hard plastic recycle

Description for plastic granulator pellet making machine

With different designs of screw, this machine can be applied to granulate the recycled material of rigid PVC, soft

PVC and waste PVC.It can be stopless in the course of production. It uses pneumatic conversion and strongwind

blowing.At the same time can adjust stainless steel storage container and can run at high speed for a long time

while extrude stably.Among the prilling machine system, our company has developed this granulating machine of

recycled waste film.The production of this machine is quite high. Therefore, it is the necessary equipment for film

manufacturers.

Process procedure for plastic granulator pellet making machine

crushing and washing machine-dewatering machine-plastic pellet machine-colling machine-cutting machine

Final product of plastic granulator pellet machines

The plastic granulating unit is a recyclable type for the professional treatment of PP/PE LDPE, HDPE,

ABS, PVC, ETC. At the same time, it also belongs to environmental protection equipment.

A large number of used woven bags, plastic film, agriculture convenience bags, etc. through the plastic

ranulation unit into the secondary processing program, providing a strong cornerstone for the furniture

industry, daily necessities manufacturing.

1.Belt conveyor: Transfer the raw material to the crusher for crushing and washing

2.Crushing and washing machine:The machine can crush the waste plastic into small piece besides wash them and then

put them into the plastic granule making machine.

3.Conveyor:delivery crushered raw material to the pool cleaning

4.Pool:Clean the crushed raw material and precipitate the impurities.

5.Pool pulley:Slide the crushed raw material of the pool to reach the other end.

6.dewatering machine:Remove the broken plastic from the pool, with the function of dehydration

7.Conveyor+Automatic feeder:converyor send broken raw materials to the feeder,the feeder connect with pellet making

machine,replace the artificial pressure into the granulator

8.Host pellet making machine :The raw material is heated and melted in this machine

9.Second pellet making machine:The melted plastic is drawn through the die in the secondary machine

10.water tank :is used to cool the plastic pellet and send the pellet to next step-plastic cutting machine.

11.Plastic cutting machine:This machine is used to cut the plastic strip into small pieces and the size of pellet can be adjusted

as your requirements.

12.Plastic pellet packing machine:packing the final product(plastic pellet)

13.Conveyor:delivery the plastic pellet to the automatic packing machine

14.Control cabinet:The temperature control cabinet control the temperature of the plastic pellet machine and also make people

asy operate the machine. Parameter of plastic film recycling line

| NO. | Item | Technical data |

| 1 | Conveyor | Power:3kw

Size: Length 5m ,

Width 0.8m

Capacity:1000-1200kg/h |

| 2 | PP PE crusher | Model:1000

Power :37kw+11kw

Capacity :1000kg/h |

| 3 | Belt Conveyor | Power :1.5kw

Size : (L) 4m* (W) 0.6mm

Capacity:800-1200kg/h |

| 4 | Automatic Feeder | Power:3kw

Capacity:800-1200kg/h |

| 5 | Main Plastic Pelleting Machine | Model : SL-260

Screw diameter : 260mm

Screw length:3.6m

Motor : 110kw |

| 6 | Vice Plastic Pelleting Machine | Model : SL-220

Screw diameter : 220mm

Screw length:L1.6m

Motor :22+18.5kw |

| 7 | Pellet Cutting Machine | Model :LY-F300

Power :7.5kw

Capacity: 800kg/h |

| 8 | Plastic Pellet Baging Machine | Power :1.5kw

Size :1000*1200*1100mm |

Packaging & Shipping

Company Profile

Our Advantages

Certifications

FAQ

Q1: Are you a manufacturer or trade company?

A1:We are a professional manufacturer for producing machinery over 10 years.

Q2: How is the quality of your product?

A2: Our products are manufactured according to national and international standard, and we have a test on every machine before delivery.

Q3: How about the price?

A3: We are a professional manufacturer and be able to provide you with the lowest price than market one. We will give you the best quotation.

Q4:What if the machine is damaged?

A5: One year warranty and all-round after-sales service. After this deadline, we shall charge at a low cost to keep after-sales service.

>>

Custom Logo Baseball Cap Advertising Hat Summer Hat Cotton Golf Sport Cap

>>

High Quality Fiberglass Pultruded Pipe FRP GRP Profiles FRP Pultrusion Tube

>>

Factory Direct Sales of The New Chinese Minimalist Ceramic Vase, Suitable as a Living Room Decorative Item, Featuring a Modern White Design.

>>

12W Strobe Flashing LED Warning Strobe Light Bar

>>

Wholesale Custom Premium Luminous American Football Official Size 1-9 Inflatable Rugby

>>

New Rich Nylon Waterproof Full Protection Camo Green Tacticaljacket Plate Carrier Body Armor Wholesale Customized Ballistic Vest Bulletproof Vest

>>

women's Sexy Skinny Faux Leather High Waist Leggings Pants

>>

New Arrival Skmei 1795 Red Leather Strap Quartz Watch Customized Logo Brand for Women

>>

Top Quality CE Hammer Mill Feed Grinder Machine in 5-10tph with Good Price

>>

Oerlikon Fairfield E01 Torque-Hub Electric Drives Gearbox for Aerial Work Platform/Zero-Turn Radius Mower and Golf Cart

>>

High Quality Energy Saving Reed for Textile Production

>>

Factory Direct Sale Good Quality Wholesale Nickle Fitting BBQ Cooking Genuine Leather Apron

>>

Wholesale Lady Large-Capacity Diagonal Cross Single Shoulder Bag Shopping Storage Bag

>>

LED Glasses for Party Cold-Light Glasses Concert Prop Halloween Prop Party Prop Bar Toy

>>

16-Inch Rose Tiffany Style Stained Glass Table Lamp with 100% Bronze Girl Base

>>

SBW-50kVA Three Phase Compensation Voltage Stabilizer /AVR/Regulator

>>

Aluminum 6061 and 7075 CNC Metal Part

>>

TEM82E Electormagnetic Inline Flow Sensor Price Flowmeter Inline Flow Meters

>>

Forged Steel Balls,Steel Balls,Forging Balls,Grinding Media

>>

100% Recycled polyester Sustainable material RPET spunbond non-woven fabric