|

US$40,000.00-150,000.00

|

1 Set

(MOQ)

|

Basic Info.

Computerized

Non-Computerized

Transport Package

Wooden Base

Production Capacity

100PCS/Year

Product Description

Product Description

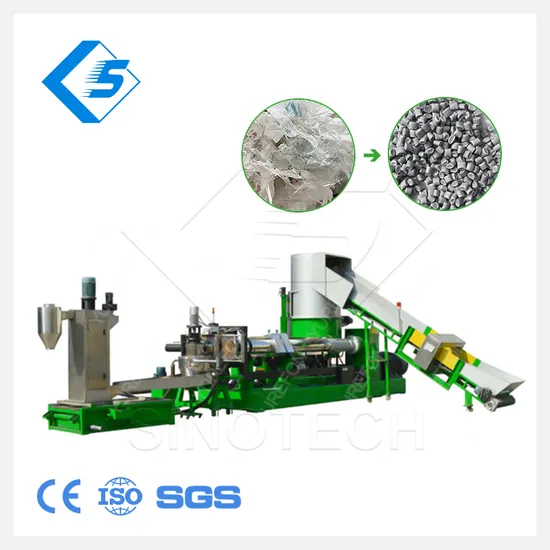

This SJ series PP PE film pelletizing line used compactor, mainly for PP, PE plastic film (such as film, bags, woven bag, jumbo bags etc) crushed to granulation, make plastic pellet full, even and without porosity, suitable for all kinds of waste plastic regeneration granulation recycling.

This SJ series compacting and pelletizing system combines function of crushing, compacting, plasticization and pelletizing to one step, used for recycling and waste plastic materials. It is equipped with automatic temperature, electric change filter screen. After loading the feeder, the crushed material can be granulated. Granulator adopts speed regulating motor. Material can be cut according to the feed rate of the extruder.

According to different material and different customer demand, we provide customer with various options, such as different L/D ratios, multiple exhaust screw structures, single and double stage design, different pelletizing die. The capacity can be 100-800kg/h.

Process flow:

Water ring cutting system:

Belt conveyor→Compactor→single shaft extruder→Hydralic screen exchanger→Die mould→Water cooling tank→Dewatering machine→Storage silo

Strand cutting system:

Belt conveyor→Compactor→single shaft extruder→Hydralic screen exchanger→Die mould→Water cooling tank→Air blower→Pelletizer→Storage silo

Product Parameters

| Single stage |

| Model | Capacity(kg/h) | Motor power(kw) | Screw diameter(mm) | L/D |

| SJ75 | 90-120 | 45 | 75 | 33 |

| SJ85 | 150-200 | 55 | 85 | 33 |

| SJ100 | 200-300 | 90 | 100 | 30-33 |

| SJ120 | 350-400 | 132 | 120 | 30-33 |

| SJ150 | 550-600 | 185 | 150 | 30-33 |

| SJ180 | 700-800 | 250 | 180 | 30-33 |

| Double stage |

| SJ75+SJ90 | 110-120 | 37+22 | 75 | 30+12:1 |

| SJ85+SJ100 | 150-200 | 55+30 | 85 | 30+12:1 |

| SJ100+SJ120 | 200-300 | 90+37 | 100 | 30+12:1 |

| SJ120+SJ150 | 300-450 | 132+45 | 120 | 30+12:1 |

| SJ150+SJ180 | 500-650 | 185+55 | 150 | 30+12:1 |

| SJ180+SJ200 | 700-800 | 250+75 | 180 | 30+12:1 |

Two cutting types optional: Strand cutter and Water ring cutter.

We can provide you with pelletizing machine as per your requirements. |

Detailed Photos

01 Compactor

It can handle both hard and soft materials. The sliding gate controls the residence time of the material in the compactor to achieve the effect of pre-drying and ensure that clean and dry material enters the barrel.Material that fails to achieve the treatment effect will not be able to enter the next process. PLC accurately controls the quantity of' forced feeding materials to ensure production capacity

02 Single Screw Extruder

A specialized single screw extruder applied to gently melt the pre-compacted material. The plastic scraps will be well melted. with double-zone Vacuum degassing system, volatile such as low molecular and moisture will be removed efficiency especially suitable to heavy printed film and material with water content.

03 Hydraulic Screen Changer

A regular single-platel/piston double-station screen changer or non-stop double-platel/ piston four-station can be installed on head of extruder to present significant filtration performance. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules

04 Water Ring Cutting System

Water ring pelletizing system set as the standard granulating method. self-adjusting pelletizing head for the best granulate quality and long uptime thanks to consistently correct blades pressure. The production line can be equipped with three kinds of granulation methods: water circumferential cutting. water-cooled stretching automatic stretching or underwater granulation.

05 Vibration Dry Machine

Advanced dewatering vibration sieve combining with horizontal-type centrifugal dewatering present high-performance dried pellets and lower energy consumption.

06 Production Silo

Storage in the production silo

Company Profile

Certifications

Packaging & Shipping

FAQ

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon.

Q: Do you provide any spare parts with machine?

A: Yes, we offer all necessary spare parts together with machine sending and 3 days spare parts delivery after machine sale.(contact us for packing list )

Q: How about your after-sale service?

A: We offer manual instruction and engineer training before loading, after shipment we provide 24 hours online support, video technical support or field installation assist.

Q: What is the lead time?

A: We have standard model machine in stock.It can be delivery within 1 week. If need to make mould, the delivery time need half month after drawing confirmed.

Q: What is the warranty period for your machine?

A: 12 months warranty for components and technical support.

Q: Do you provide custom machines?

A: Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: What's the advantage of SINO-TECH?

A: We provide customers with turnkey projects. Including plant design, blow molding machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time for customer.

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon.

Sales Manager:Janey He

Tel:+86 512 58492269

Add:509,Xinhongji Mansion,No.28,Huachang Road,Zhangjiagang,Jiangsu,China

>>

Garden Basket Fruit Picker Head Multi-Color Plastic Fruit Picking Tool Catcher Agricultural Bayberry Jujube Picking Supplies

>>

Awholesale Fashionable PVC PU Single Sided Self Adhesive Synthetic Leather with Adhesive for Sofa

>>

IR infared heating lamp quartz infrared heat lamp OYATE infrared heating lamp for industrial heating white infrared single tube lamps

>>

Silicone Foam Dressing 10*10cm Adhesive

>>

Concrete Mixer Truck Hot Sale Cement Roller Transporter Construction Machinery Construction Truck 8m3 Cube

>>

Fluorine Anti Cavity 4.25oz Fresh Mint Toothpaste

>>

Sanitary Stainless Steel Food Grade Outward Pressure Top Manway with Ss Handwheel

>>

Easy home balcony standing courtyard large clothes rail drying rack

>>

150GSM 4X5m Blue Waterproof Tarp Tarpaulin PE Tarpaulin,

>>

Dual Frequency Flow Automatic Down Plastic Paper Horizontal Pillow Packing Machinery For Disposable Toothbrush

>>

Laminated Jwc Transparent Film for S, M, L, XL Baby Diaper Making Machine

>>

OEM 06H103319Q 06K103319A TG1508 Timing Gear for AUDI Apply Engine CCTA CCTB

>>

Sleep Proof Finger Sleeves Seamless and Breathable Thumb Finger Stall

>>

High-Quality Fiber Laser Cutting Equipment with High Reliability and User-Friendly Operation

>>

Car parts Front Rear bumper Auto parts Front Rear bumper for chevrolet aveo 2008 96808139

>>

Fully-automatic Bag in Box Filler for Webbed 2-25L BiB Bags

>>

Oil Free Vacuum Pump Small Dry Corrosion-Resistant Oil-Free Screw Vacuum Pump

>>

Good Quality Agriculture Waste to Organic Fertilizer Processing Line with Compost Pellet Making Equipment

>>

High Speed PVC Hot and Cooling Mixer Machine

>>

Yosion TEchnology YX-DT1800 Workbench with Dust Filter;Environmental Protection Equipment