|

US$28,500.00-182,000.00

|

1 Set

(MOQ)

|

Basic Info.

Processing Accessory

Chuck CNC Lathe

Guide Rail

Inclined Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Automatic Grade

Automatic

Certification

GS, CE, ISO 9001

Control System

Fanuc, Siemens, Mitsubishi

Motor Power

11,15,18.5,22kw

Transport Package

Plywood Case

Specification

4000x2110x2100

Production Capacity

1000/Year

Product Description

Product Description

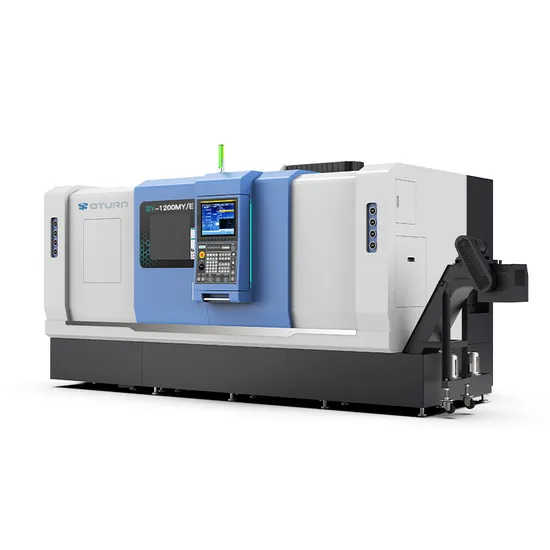

The two-axis lathe revolutionizes efficiency by allowing simultaneous processing of both ends of a workpiece in a single clamping. This innovation simplifies manual operations, boosts output, and minimizes processes. The second spindle ensures comprehensive turning and seamless workpiece transfer during machining, thereby slashing cycle times. Designed with a 30-degree incline, the machine offers high precision, exceptional rigidity, and superior cutting stability. Its robust lathe bed, crafted from one-piece high-strength HT300 cast iron and refined through finite element analysis, guarantees mechanical rigidity and stability. This results in long-term accuracy, enhanced processing stability, extended tool life, and improved accuracy stability thanks to stress relief treatment. Featuring a high-strength roller linear rail design and a screw pre-tension transmission system, the machine delivers remarkable rigidity performance. Its sleek and elegant appearance aligns with contemporary trends, making it not just a powerful tool but also a stylish addition to any workshop.

Main features of this machine tool:

1. Equipped with a direct drive synchronous electric spindle device, utilizing a magnetic ring incremental encoder (sine and cosine) with a positioning accuracy of 20 arc seconds and a C-axis indexing accuracy of 40 arc seconds. This effectively eliminates spindle vibration, maintaining nose deflection accuracy within 0.002MM. A rear-mounted rotor facilitates faster installation and maintenance, while the spindle motor's cooling system suppresses thermal displacement, ensuring a constant operating temperature. Undergoing rigorous dynamic balance testing, the spindle system retains excellent accuracy, high rigidity, and efficiency, supporting both fine finishing and rough machining. It's ideal for mass production of intricate and high-smoothness products.

2. The high-rigidity integrated design servo power turret enhances rapid and precise tool changing performance. Coupled with high-speed power axis milling, it achieves outstanding combined turning and milling capabilities. The turret uses a high-rigidity BMT installation interface, driven by a servo spindle motor for power transmission.

3. With roller linear guides and precision-ground ball screws, this machine ensures optimal accuracy and durability. Each axis employs a direct transfer structure and a double-anchor pre-relay method to minimize thermal displacement, significantly boosting processing accuracy. The high-rigidity, large-sized, heavy-duty linear slide rails maintain accuracy under impact, provide smooth, low-noise displacement, and extend machine life.

4. This machine boasts a comprehensive hydraulic and lubrication system, utilizing high-quality hydraulic pumps, valves, and components to drastically reduce failure rates. The system is designed for simplicity and reliability, ensuring smooth operation.

5. Featuring a Taiwan rotary chuck cylinder and an optional automatic chip removal device, this machine significantly reduces operator labor intensity, enhancing safety and production efficiency. Programmable and controllable, these functional components can be tailored and installed according to specific user requirements, including special fixtures.

Product Parameters

| Name | Unit | ESY1200MY |

| Max. swing diameter over bed | mm | Φ680 |

| Max. processing diameter | mm | Φ400 |

| Max. processing diameter on tool holder | mm | Φ300 |

| Max. processing length | mm | 1000 |

| Spindle nose | type | A2-8 |

| Max. Spindle speed | rpm | 2100 |

| Cylinder/Chuck | lnch | 10″ |

| Spindle bore diameter | mm | Φ86 |

| Bar diameter | mm | Φ72 |

| Spindle motor power | kw | 24 |

| Spindle direct drive motor torque | Nm | 160-390 |

| X/Z/Y axis limit travel | mm | 285/1140/120(±60) |

| X/Z/Y axis rail specifications | spes | 45/45/35Roller |

| X/Z/Y axis motor power | kw | 2.9/2.9/1.8 |

| Positioning accuracy | mm | ±0.005 |

| Repeatability | mm | ±0.003 |

| X/Z/Y axis rapid movement | m/min | 24/24/8 |

| Power turret type | pcs | BMT65-12T |

| Power turret power | KW | 5.0 |

| Max. speed of driven tool holder | rpm | 5000 |

| Outside diameter tool holder specifications | mm | 25X25 |

| Inner diameter tool holder specifications | mm | Φ50 |

| Adjacent tool change time | sec | 0.2 |

| Hydraulic tailstock | / | Hydraulic tailstock |

| Max. travel of tailstock | mm | 800 |

| Tailstock sleeve tapered hole | type | Mohs5# |

| Tailstock sleeve diameter | mm | Ф100 |

| Sleeve stroke | mm | Fixed |

| Machine size | mm | 4000x2110x2100 |

| Machine weight | kg | 7200 |

| Cutting fluid tank volume | L | 250 |

| Cutting water pump | kw | 0.75 |

| Hydraulic unit box volume | L | 40 |

| Hydraulic oil pump motor power | kw | 1.5 |

| Lubricating oil tank volume | L | 2 |

| Automatic lubrication pump motor power | W | 50 |

| Cooling water pump power | W | 750 |

Products Configurations

Company Profile

Quality Control

Our Advantages

FAQ

Q1: How can I choose the most suitable machines?

Please provide us with your specifications so that we can select the best model for you. Alternatively, you may choose the exact model you need or send us the product drawings, and we will recommend the most suitable machines for you.

Q2: What are the main products of your company?

We specialize in a variety of machinery, including CNC Lathe Machines, CNC Milling Machines, CNC Turning Machines, Vertical Machining Centers, Horizontal Machining Centers, Lathe Machines, and Turning and Milling Composite Processing equipment, among others.

Q3: Where is our factory located? How can I visit there?

Our five factories are located in Guangzhou, Quzhou, Ningbo, and Guangdong. You are warmly welcomed to visit us at any of our locations.

Q4: How do you transport the equipment?

We offer comprehensive transportation solutions including DDP, CIF, FOB, and FCA.

Q5: What are the payment terms?

We accept T/T payments, with a 30% initial payment when the order is placed and the remaining 70% before shipment.

Q6: What is the Minimum Order Quantity (MOQ)?

A: The MOQ is 1 set. However, some lower-cost machines may require a higher quantity.

We want to know:

1. We strongly suggest you provide the size and material of your workpiece for our evaluation. If possible, please send us the workpiece drawing so we can recommend the most suitable model.

2. If you need a CIF price, kindly inform us of the port of destination.

>>

Wholesale 13X4 4X4 13X6 360 HD Transparent Unprocessed Brazilian Virgin Hair Free Part Lace Front Human Hair Wig

>>

Hand-Held Pulse Laser Cleaning Machine Remove Paint Machine 300W

>>

2020 Stainless Steel Jacketed Double Layer Mixing Heating Tank Price

>>

Lotus Shape Wall Hanging Pendant with Iron Ring Electric Fireplace Fan

>>

5 Axis CNC Bridge Saw with Head Tilting and Rotation

>>

Premium 3L 5L 12L 20L 30L stainless steel round pedal bin soft close inner bucket home bathroom kitchen trash bin

>>

Staminapro Triple Station Outdoor Pull-up Bars

>>

Water Check Waterproof 3 Way Needle Wall Mixing Plastic Valve

>>

SIM800 pin to pin sim900a sim900 quad band gsm gprs module

>>

Small Aluminum Fins Heatsink for Laser Hair Removal Device

>>

High Quality Fitness Polyester Battle Rope for Exercise

>>

Ma6000 Bottle Pump Head Press Injection-Molding-Machine

>>

Taijia U5200 Ultrasonic Detector Pulse Velocity Tester for Concrete Ultrasonic pulse tester

>>

High Quality Agricultural Farming Gasoline in China

>>

Customized Sublimation Hoodie with Lion Pattern

>>

500kg 1000kg 2000kg Drying Mixing Machine for Plastic LDPE HDPE Injection

>>

Cordless Electric Cutting Machine for Cloth

>>

Custom Full Capacity High Speed Class 10 Mini TF SD Card U3 4G 8g 16GB 32GB 64GB 128 GB 256g 512GB Storage Card for Smart Device

>>

Corsair Axi Series Ax1600I 1600W ATX 80 Plus Titanium Certified Full Modular Digital ATX Power Supply

>>

Small Scale Industrial Electric Hydraulic Egg 30l Autometic Fish Sausage Stuffer Making Maker Machine