| Negotiable | 1 Piece (MOQ) |

| Spindle Specification and Parameter | |||

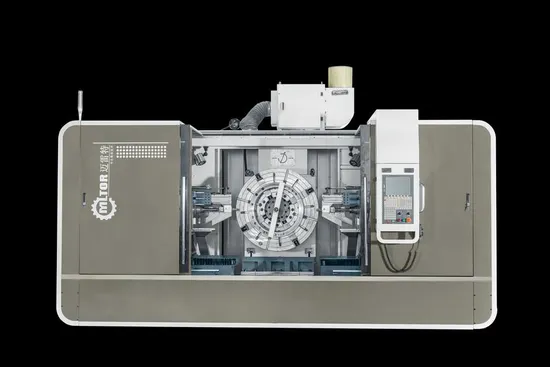

| Item | Main specification detail | Unit | MLT-SK4H1400i |

| 1 | Number of spindle | 4 | |

| 2 | Min inner diameter of ring die | mm | 350 |

| 3 | Max. Outer diameter of ring die | mm | 1450 |

| 4 | Max drilling depth | mm | <120 |

| 5 | Drilling hole size | mm | φ3-φ12 |

| 6 | Max rotation speed | r/min | 13000 |

| 7 | Max. Width of ring die die | mm | 550 |

| 7 | Spindle motor | kw | 2.2 |

| 8 | speed adjustment mode | Vector frequency | |

| 9 | Fitting shank bit | Ø10,Ø4 | |

| 10 | Clamp mode | Plug-in sealing+collet chuck locking | |

| 11 | Drill bit guiding mode | Slide arm following type | |

Special Feature: 1. Axis spacing display (drill spacing):NC system comes with digital display, spacing out of tolerance alarm, the system automatically calculates the drill spacing, real-time digital display of headstock displacement, with position out of tolerance alarm, completely eliminating human error One-key calibration: Z228i's unique calibration mode, one-key rotation, smooth acceleration, reduce the impact of the turntable, and extend the life of the turntable Hole surface spiral suppression technology (SHST): The unique surface spiral suppression technology (SHST) of the Mltor gun drill system can effectively eliminate the spiral line phenomenon in the hole and improve the quality Processing remaining time: automatic calculation and real-time update according to the feed rate Drill bit spacing and remaining row calculation: one-key realization, automatic calculation,no need for operator to calculate Back to designated row and hole function: input designated row and designated hole, automatic return, one-key realization 7. Even-numbered hole verification: to prevent artificial input hole number errors | |||

| NC Control specification | |||

| 18 | NC system | MLT-Z228 | |

| 19 | Display size | 12" LCD/TFT color LCD | |

| 20 | System Language | English | |

| 21 | Unit | Metric system | |

| 22 | Control axis qty | 4-Axis servo linkage | |

| 23 | Programming | No need programming | |

| 24 | Control mode | Auto,Manual+Hand wheel | |

| 25 | Drilling mode | Normal drilling,side row unequal depth relieving hole,whole relieving hole | |

| 26 | Each row hole qty verification | Odd hole is invalid | |

| 27 | Hand wheel | Spring wire three proofing HW | |

| 28 | Power shortcut memory | Support | |

| 29 | Single hole drilling | Support | |

| 30 | Definite number drilling | Support | |

| 31 | Air-pressure protection | Support | |

| 32 | Oil-pressure protection | Support | |

| 33 | Rotate speed protection | Support | |

| 34 | Processing database | Support | |

| 35 | Abrasive drilling count | Support | |

| Machine tool specification | |||

| 36 | Machine base structure | T+1-type strengthen machine base | |

| 37 | Machine base marl | Cast iron | |

| 38 | Machine base support foot | 14 | |

| 39 | Linear guideway | X:RGW55 Y/Z:HGH45 | |

| 40 | Ball screw | 4005 | |

| 41 | Axis-C travel range | 360° random rotation | |

| 42 | Max loading of turntable | kg | 600 |

| 43 | Metal plate protective housing | Whole sealing protection | |

| 44 | Housing color | Gray & white | |

| 45 | Main engine NW | kg | 7800 |

| 46 | Whole machine weight | kg | 9500 |

| 47 | Main engine floor space | mm | 4120*2210*2790 |

| 48 | Whole machine floor space | mm | 4120*3600*2790 |

| 49 | Ring die clamp mode | 4-paw chuck | |

| 50 | Chuck diameter | mm | Ø800 |

| 51 | Max ring die width | mm | 520 |

| 52 | Max ring die weight | kg | 600 |

| 53 | Axis-X travel range | 600 | |

| 54 | Linear guideway mode | Heavy load pin roller linear guideway | |

| 55 | Feeding axis X Max-speed | mm/min | 6000 |

| 56 | Y&Z/Feeding axis Max-speed | mm/min | 6000 |

| 57 | Stop block | On-off switch stop | |

| 58 | Back to zero device | Support | |

| 59 | Max stroke of carrige | mm | 450 |

| 60 | Carrige quantity | 2 | |

| 61 | Stop block | Support | |

| Chip-removal filter system | |||

| 62 | Magnetic chip removal | Support | |

| 63 | Chip removal device | Magnetic chip removal | |

| 64 | Liquid level switch control | Support | |

| 65 | Liquid level out of limit alarming | Support | |

| 66 | Mag-CR status protection | Support | |

| 67 | Trolley structure | Double-deck drop oil | |

| 68 | First-level filter | Strong magnetic adsorption by chip removal device | |

| 69 | Second-level filter | Sediment+magnetic bar absorption | |

| 70 | Third-level filter | High mesh filter cloth | |

| 71 | Filter device size | mm | 2400*660*1100 |

| 72 | Filter device weight | kg | 380 |

| High-pressure jet-flow system | |||

| 73 | Oil-pump quantity | 2 | |

| 74 | Oil-pump type | MOOG D952+YUKEN AR22 | |

| 75 | Motor power | kw | 7.5 + 5.5 |

| 76 | Max pressure | bar | 150 |

| 77 | Max flow | L/min | 62 |

| 78 | Gross cubic capacity | L | 1000 |

| 79 | Pressure and flow adjustment | Manual | |

| 80 | Pressure display | Mechanical pointer+digital readout | |

| 81 | Pressure meter switch | Support | |

| 82 | High pressure filter | Support | |

| 83 | Differential pressure | Support | |

| 84 | Pressure monitor | Support | |

| 85 | Liquid level monitor | Support | |

| 86 | Oil temperature monitor | Support | |

| 87 | Oil temperature control | Air con cooling/ Water cooling device | |

| 88 | System device weight | kg | 680 |

| 89 | System device floor space | mm | 1600*1100 |

| Cooling system | |||

| 90 | Oil cooling device type | YLD80PA(standard configuration) | |

| 91 | Refrigerating capacity | Kcal/h | 8000 |

| 92 | Oil pump flow | L/min | 27 |

| 93 | Water cooling machine type | SL4-30 (optional) | |

| 94 | Spindle cooling | NA(Natural cooling) | |

| 95 | Assit-hydraulic cooling | NA(Natural cooling) | |

| Oil mist treater | |||

| 96 | Treater mode | Centrifugal mode | |

| 97 | Treater type | HCE-120D1 | |

| 98 | Consumable marl type | LX-120D1 | |

| Lubrication system | |||

| 99 | Lubrication type | Elec-intermittent lubrication | |

| 100 | Lubricant-pump | MY2232-200T | |

| 101 | Oil-empty alarm | Buzzer alarm,system reminding | |

| 102 | Oil distributor type | Ration oil distributer | |

| 103 | Lubrication point count | 15 | |

| 104 | Lubrication oil # | 32#-46# Hydraulic oil | |

| Electric system parameter | |||

| 105 | Electric component | Schn | |

| 106 | Spindle transducer | Mitsubishi | |

| 107 | Terminal | Phoenix | |

| 108 | Spindle motor | ABB | |

| 109 | Cabinet air-con | DLW5 | |

| 110 | Total power | kw | 25 |