|

US$48,000.00

|

1 Piece

(MOQ)

|

Basic Info.

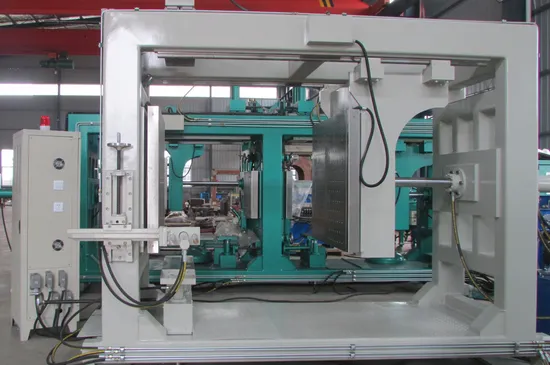

Type

Injection Blow Molding

Plastic Type

Thermoplastic

Plasticizing Way

Plunger Type

Clamping Way

Hydraulic & Mechanical

Computerized

Computerized

Certification

CE, ISO9001:2008, GMP, QS

Core Components

PLC, Engine, Bearing, Gearbox, Motor, Pressure Ves

Clamp Plate Size

1000*1200mm

Min Max Clamp Plate Stroke

240*1250mm

Upper&Lower Core Puller Stroke

760*350mm

Hydraulic Power Pack

7.5kw

Horizontal Tilting Angle

0-7 Degree

Transport Package

Customized

Product Description

Product Description

1. Use:

The APG device is controlled by the human-machine interface, the template size can be customized, and can support two sets of molds produced together, greatly improve production efficiency, especially for products with simple structure, such as insulators, bushings, sensors, etc.

The APG equipment is controlled by PLC system, man-machine interface, template size can be customized, temperature, pressure can be set, flow rate, pressure holding time, automatic boot, automatic heating, automatic filling, multi-level administrator control, and can save products parameter, automatic cycle production, can save hundreds of product parameters, greatly convenient user production, improve product efficiency and product quality.

Application

1. Pole mounted distribution transformer pressure gelation molding machine is applicable for electric resin epoxy products such as transformer, 12KV-1250A, contact box, 40.5KV bushing, bending plate, upper and lower shell of SF6 insulating cover,etc.

2. Pole mounted distribution transformer pressure gelation molding machine is large and medium-sized equipment, mould plate is 800*600mm, length of upper and lower core-pulling stroke can be determined according to the product

This machine is full automatic,Servo and PCL touch screen control. Machine, the clamp plate size can customized, greatly improved efficiency and product quality. Advantages:

1. Servo motor control

2. PLC touch screen Control

3. Can save more than 100 product datas.

4. Fully automatic design

Auto start machine&heating clamp plate

Auto setting hydraulic pressure

Auto setting heating temperature

Auto setting valve flow

*Machine Technical Parameters

| Clamp Plate Size | 1000*1200mm |

>>

Food and Beverage Stir Tank

>>

Good Quality Home Decoration Custom Soy Wax Glass Jar Scented Candle

>>

56m Concrete Pump Truck for Construction

>>

2020 Real-time Monitoring Of Heart Rate Medical Instrument For Cancer Detector

>>

Kitchen Countertops and Washstands Making Stone CNC Machine

>>

Motorcycle Parts of Motorcycle Alloy Wheel Rim of 1.60-18 1.60-19 1.40-18 1.85-18

>>

Stainless Steel/AISI 1045 Steel Zinc Plated 65mm Go Kart Spring

>>

Hot-selling Xiaomi Yunmi portable electric kettle mini kettle for boiling water, essential for travel

>>

18 Inches Tall Freezable Coil Glass Pipes with Double Beaker Bottom Hookah Freeza Glass Smoking Water Pipe

>>

DN25mm wireless multi-jet bronze cold water meter

>>

8 Inch 216mm Embedded Kiosk Printer X216-II A4 Paper Thermal Printer

>>

Multi Axle 18 Meters Truck Low Bed 80-120ton Special Low Boy Lowbed Semi Trailer

>>

Coating thickness gauge NDT equipment

>>

Low Altitude Surveillance Radar Series Products

>>

Interior-Opening UPVC Door for Residence Custom House Villa PVC Door Solutions Prefabricated Energy Saving Other Casement UPVC Door with Double Glazing

>>

Lantern Lights Drop Shipping Simulation Personal See Through Small Fireplaces Accessories

>>

Precision CNC Machined Aluminum, Copper, Brass Bicycle Components

>>

Car Modification Parts for Honda Mobilio Auto Electric Tailgate Back Trunk with Kick Sensor

>>

Custom Ladc12 Ed Street Light Housing Housings Die Casting Aluminum

>>

T&L Brand FBE Series Auto Panel bender machine CNC Bending Center