Basic Info.

Drivetrain

Main Drivetrain

Spindle Speed

Max: 80PCS/Min

Process Type

Heavy Processing

After-sales Service

1 Year

Max Allowed Wood Size

3000*450*500mm

Size of Planer Tool

3200*200*19mm

Slicing Thickness

0.2-3mm

Slicing Speed

Max: 80PCS/Min

Wood Clamping Method

Hydraulic Control

Knife-Holder Quick Back Motor

4.5kw (Servo Motor)

Circulating Heat Water Motor

0.75kw

Veneer Trasport Motor

0.5kw

Overall Size

6800*4500*3700mm

Transport Package

Plastic Films

Specification

6800*4600*3700mm

Production Capacity

15sets/Month

Product Description

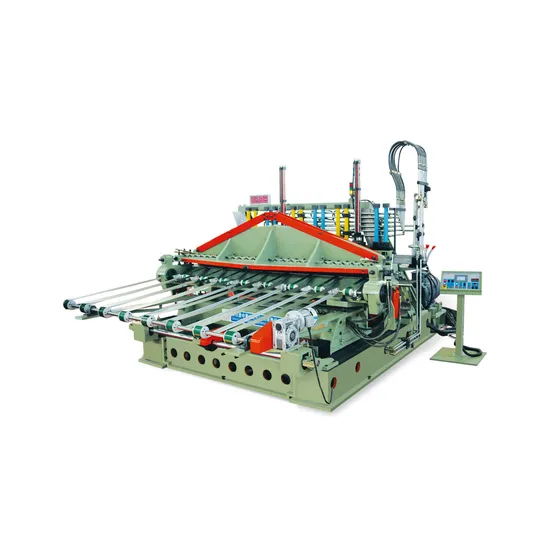

We supply high quality BB1332 BB1335 Vertical Veneer Slicer

Product Show

1.Product Show

Product Description

2.Product Description

| MODEL | BB1332 | BB1335 |

| Max allowed wood size | 3000*450*500mm | 2500*500*500mm/3300*400*500mm |

| Size of the knife | 3200*200*19mm | 3500*200*19mm |

| Slicing thickness | 0.2-3mm | 0.2-3mm |

| Slicing speed | max.80pcs/min | 18-80pcs/min |

| Wood clamping method | Hydraulic control | Hydraulic control |

| Total power | 41.25kw | 50.25kw |

| Main motor | 30kw | 37kw |

| Hydraulic motor | 5.5kw | 5.5kw |

| Knife-holder feeding motor | 4.5kw servo motor | 5.5kw servo motor |

| Circulating heat water motor | 0.75kw | 0.75kw |

| Veneer transport motor | 0.5kw | 1.5kw |

| Size of body | 6800*4600*3700mm | 6800*5000*3700mm |

| Net weight | 21T | 24T |

Function

3.Function

It is mainly for slicing solid wood, engineer wood and other composite board, working efficiency is high, and veneer thickness is uniform. It is widely adopt in decorative veneer of plywood, furniture, flooring, construction industry and so on.

Characteristics

4.Characteristic

1 Main motor adopts frequency motor, with famous brand inverter. Energy can be feed back by the special design, and cutting speed improved to be 80pcs/min

2 To guarantee precise veneer thickness, we use ball screw with servo motor. To avoid veneer scratch we used auto blade back system

3 Use hydraulic system, log clamping become more convenient for operator and improves efficiency

4 Control cabinet is combined with electric and hydraulic system, make it easy for single operator

5 Automatic hydraulic blade holding system, and log holder auto turn back system are fitted there, grinding and replacing the blade become so easy and quickly

6 Heating system in blade holder and press bar, avoids stain in the veneer to improve veneer quality

7 Pneumatic brake systems can stop the machine at any required position, and restart promptly. It is convenient for the operator to adjust the log, and safety also guaranteed

8 Self lubricating center can automatically apply lubricant regularly to every moving mechanism, guarantee movement normally smoothly and precisely.

Company Profile

5.Company Information

Qingdao Haozhonghao Woodworking Machinery Co., Ltd. previously was Qingdao Woodworking Machinery Manufacturing Company, and was established in 1958.

With more than 50 year experience in making woodworking machines, our main products are Sanding Machine, Panel Saw, Guillotine, Veneer Slicer and Grinder. We firstly put BB1342 vertical slicer into the market in China. We developed BB1135B Horizontal Veneer slicer by integrating the internal and international technologies, the max slicing width reaches 1300mm. We are the first company which was certified by ISO9001 in the industry, and also a hi-tech enterprise in Qingdao.

We have more than ten years experiences in exporting high quality woodworking machinery, especially Sanding Machine, Veneer Slicer and Grinder.

Our website is sanding machine.en.made-in-china.com; you could get more information about our company and our products. hi-tech enterprise in Qingdao.

We have more than ten years experiences in exporting high quality woodworking machinery, especially Sanding Machine, Veneer Slicer and Grinder.

Our website is sandingmachine.en.made-in-china.com; you could get more information about our company and our products.

>>

Sapphire Watch Parts

>>

Spa hottest!acne laser treatment price/ipl acne therapy machine/rf skin tightening skin repair

>>

Cold Forging Screw Moulds for Automotive Fasterning Technology

>>

Weijia 52" X 52" Colorful Textured Gingham Vinyl Tablecover with Flannel Back

>>

Women′s Zipper Long Wallet Clutch Purse

>>

Wholesale Customized PVC Motorized Waterproof Cover Retractable Roof Pergola Canopy

>>

Hot Sell New Construction Machines Hydraulic Concrete Spraying Shotcrete Machine

>>

Hot Sale Inflatable Boat Boat PVC Fishing Kayak for 2 Persons

>>

Aluminum Diameter Rollers with Different Handles

>>

Low Price Urgent Sale! Second Hand Putzmeister 38m Refurbished Concrete Pump

>>

Tensioner For ACURA Parts No.31170R40A01

>>

2-Roll Metal Axle Straightening Machine for Sale

>>

Plastic Drum Blow Molding Machine

>>

Wuhu Truchum Manufacture Direct Sales Brass Alloy Wires for Hardware Screw.

>>

Stainless steel flattened expanded metal mesh for filter

>>

Men′s Boy′s Polyester Waterproof Swim Shorts Printing Board Shorts Navy Apparel Trousers

>>

Wholesale Metal Eyelets and Hooks

>>

Voice Medium Size Large Screen Student Exam Office Cash Register Stationery Calculator

>>

1tons Three Side Discharge Concrete Mixer (SD100M)

>>

Top selling facial peeling machine crystal microdermabrasion machine to remove blackhead acne for beauty salon