|

US$2,000.00-200,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Furniture, Electronic, Home Use

Material

ABS,PA,PC,PE,PP,PS,PVC,POM etc

Cooling

3D Printing Water Line,Baffles,Sprin Piple

Part Size Range

up to 2000mm

Design Capability

Full 2D&3D Design,Dfm,Mould Flow Analysis

Stardard Delivery

30 Days

Quality Assurance

Design Control,Steel Hardness Inspection Report

Transport Package

Wooden Box or Customised

Production Capacity

100, 000 PCS/Year

Product Description

Mold Type: In Mould Decoration,Injection Mould,Plastic Mould,Overmould

| Product Name | plastic injection mould |

| Product Material | S45C,S50C,P20,S136,S136H,718,718H,2738,2316,2083,2311,etc |

| Product Material | ABS,PE,PA6,PA66,PP,PC,POM,PMMA,EVA,PU,TPU,PVC,TPR,TPE,etc |

| Surface Finish | Crude polishing,milling,Graining,IMD,paiting,mirror polishing,EDM,etc |

| Runner system | cold/hot |

| No.of Cavity | Single/Muti |

| Mould Life | 300K-1000K Shots |

| Leadting Time | 20-60 Days |

| Certificated | ISO9001 |

| Trade Terms | FOB,CIF |

| Payment Term | T/T,L/C |

| Payment condition | 30%~50% deposit in dadvance,balance 70%~50% after sample comfirmed |

| Design Software | UG/AUTO CAD |

| Port Of Loading | Shanghai port |

| Package | Wooden box or customised |

Our Services

We are an experienced company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market. From 1998 we have been engaged in the manufacturing sector.We are also an OEM/ODM factory, we will always offer customized products to meet your needs.We have a group of professionals with many years of experience in mold design, molding technology and Quality control. Our CAD designers teams will ensure that your imagination is incorporated into the actual product! We provide different kinds of products which include :

-Custom Plastic Injection Parts

-Die Casting Molding

-High Precision Moulds -Multi-cavity plastic parts -Insert & over molding -Unscrewing Molding -Gas-assisted Molding -Foam Injection molding -Gas Assist molding -Elastomeric molding -Thin wall plastic molding -High temperature molding

About US

Jiangsu Huinuo technology Co., Ltd is a specialized manufacturer, researcher and developer of various moulds and plastiHuinuoc parts and metal parts.

Based on the precision tooling, high technology and professional design, our company has built up good cooperative relations with domestic and international customers. The products are exported to US, Europe, Japan, Australia and many other countries. The good quality and service has won favorable comments from all over the world.

One of our factory

R&D center

One of our warehouse

Part of our plastic injection machine

Our Advantages: * Competitive Price

* Quick Delivery time

* ISO Certificated with the srtictest quality control system

* 20Years Mould-making and Plastic procwss experience

* Advanced equipment and Skilled workers

How to order :

Please kindly contact or email us your inquiry or RFQS with details. Our sales team would contact you ASAP and offer professional consultation on all your plastic molding needs and provide the best price.

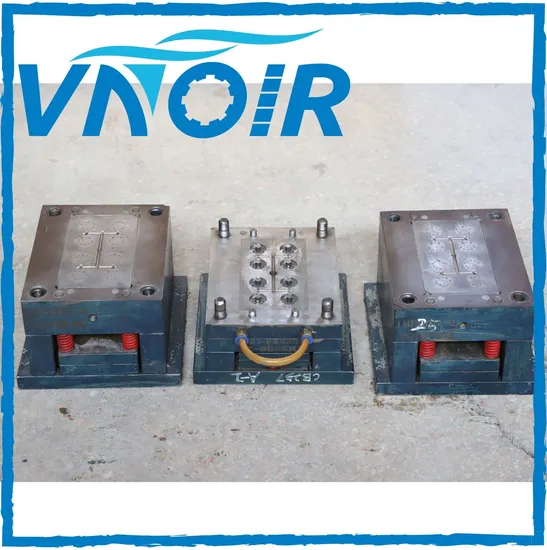

Products show:

FAQ

1. Are you a manufacturer or a trading company?

We are a mould manufacturer located in Yingxing City, China,we are close to Shanghai, we have over 20 years of rich experience, professional mould design and mould manufacturing team, design-mould making-production-assembly-shipping, providing you one-stop custom injection mould service.

2.How many kinds of moulds can you make? We can offer plastic injection moulds,rubber moulds, two-color moulds, etc. 3.How to get a quote? Detailed 2D Product Drawing&3D File (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 4.Can I get a quotation without drawings? Of course! Samples, pictures or detailed size drafts please feel free to send them to us. 5. How long is the lead-time for mold? It all depends on the products' size and complexity. Normally, the lead time is 15-25 days. 6.Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 7. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 8. How to pack the moulds and products? For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on themould, finally pack into non-fumigation wooden caseAnd as to products, we will pack into standard export cartons or as per customers request to pack

>>

NAVIFORCE NF9153L Men's Fashion Watches Chronograph Watches Multifunction Digital Quartz Wristwatches

>>

Cast iron Concrete Mould Concrete Compression Test Mold 150mm

>>

Large Metal Outdoor Apartment Waterproof Free Standing Package Box Parcel Mail Boxes Letterbox

>>

M5 /M4 Magnet for Electronic Jacquard Module Modules for Textile Machinery

>>

Direct Dyes Gray 4gl 200% Black 62 for Paper Textile

>>

High-Quality Cow Automatic Milking Machine for Sale Online

>>

Custom Machining Precision Metal Structure Tensile Bending Parts/Stainless Steel Sheet Metal Parts

>>

Taijia Load Cells Weight Measurement Wireless Marine Load Cell Crane Scale

>>

Bamboo Knitted Mattress Ticking Fabric Jacquard Textile

>>

SMT KIC start Thermal Profiler with 6 Channels for Reflow Oven SMT pare parts

>>

LED Video Wall Full Color Indoor Outdoor with P1.25 P1.56 P1.66 P1.87 P2 P2.5 P3 for Advertising Rental Billboard Display Screen Panel China Price

>>

1000W 1500W 2000W Handheld 3 in 1 Laser Machine with Touch Screen

>>

CAS 6359-82-6 Acid Yellow 11 (Acid Light Yellow G)

>>

Marzocchi Hydraulic Motor

>>

Fresh Olive Cherry Core Remove Machine/Apricot Fruit Stonce Extrator Machine

>>

Reliable Mixing Equipment for Mushroom Growth Substrates

>>

Cabin air filter for AUDI OEM 4H1 819 429A

>>

Ruian Plastic Granulator 150L /Mingde Machinery

>>

CNC/Mnc Metal-Cutting Blin Plywood Case Machine Tools Heavy Duty CNC Lathe

>>

Plastic seal tag with Satin woven tags