Product Description

Product Description

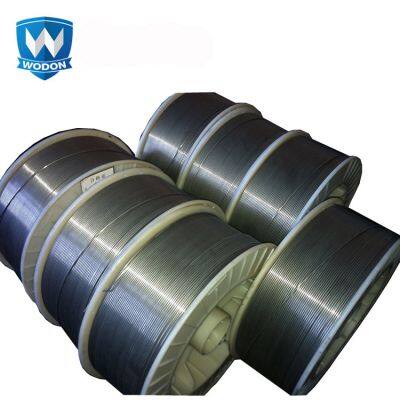

HB-YD788 high wear resistant hardfacing cco flux cored soldering wire Product DescriptionHB-YD788Diameter1.2mm;1.6mm; Main ingredientCCrSiMnContent3.0-4.524.0-30.00.50-1.500.50-2.50Hardness(HRC)HRC 55-63PackagePackage: 15KGS/Coil. No joints, weight can also be customized.InstructionHB-YD788 welding wire is a high wear resistant hardfacing wire, with hardness above 58 HRC, used for hardfacing of wear structural components. The wear resistantce is 20-30 times higher than carbon steel and the recommended overlay thickness is 20 mm or below. It is suitable for hardfacing of agricultural machinery, mining equipment which need good resistance for abrasive wear, such as hopper, shovel, mud pump and crusher. We develop our High quality self shielded wear resistant flux cored welding wire always according to plate's characteristics. This guarantees good performance regarding no clearing slag, low welding spatter, smooth surface, high welding efficiency and a transition coefficient above 0.9Our production capacity is 5000 tons wear plate welding wires per year, positioning ourselves as one of the main players on both domesitc and overseas markets. Our stable quality and good service result in increasing domestic and export sales year by year. HB-YD788 high wear resistant hardfacing cco flux cored soldering wire Wear Resistant Flux Cored Welding Wire HB-YD788Diameter1.2mm;1.6mm; Main ingredientCCrSiMnContent3.0-4.524.0-30.00.50-1.500.50-2.50Hardness(HRC)HRC 55-63PackagePackage: 15KGS/Coil. No joints, weight can also be customized.InstructionHB-YD788 welding wire is a high wear resistant hardfacing wire, with hardness above 58 HRC, used for hardfacing of wear structural components. The wear resistantce is 20-30 times higher than carbon steel and the recommended overlay thickness is 20 mm or below. It is suitable for hardfacing of agricultural machinery, mining equipment which need good resistance for abrasive wear, such as hopper, shovel, mud pump and crusher. Main Features1. Chemical Composition: High carbon high chromium2. Hardness: HRC58-653. Good Performance: no clearing slag, low welding spatter, smooth surface, high welding efficiency, stable filling rate, etc.4. Welding wire without any joints.5. Production Capacity: 8000 tons per year6. Short Delivery Time: Generally 7 days7. We have many experienced professionals to research and develop welding wires according to customers' specified chemical compositions.8. We can recommend proper welding wires and provide technical solutions based on working conditions.9. On site inspection and third party inspection are available.10. As an ISO9001:2008 approved manufacture, our mission is to improve our management system and provide high quality products continuously. Related Products WD Wear Resistante Flux Core Welding Wires. Squeezing Roller Hardfacing Wires.Vertical Cement Mill Hardfacing Wires.Gas Shielding Hardfacing Wires.Coal Conveying Groove Hardfacing Wires. Packaging & Shipping Packaging Size1.15m*1.15m*0.88m, 1.15m*0.58m*0.88m,Customized.Delivery TimeGenerally 7 days Packaging Details 150-250kgs/drum, Steel Pallet, film, Customized Company Information Jiangsu Wodon Wear Resistant Material Co.,Ltd(CHINA WODON), located in the northern international shipping center TIANJIN. The company possesses many experienced senior engineers who provides professional solutions in high wear and abrasion resistant applications. Our products have been widely applied to electric power, cement, mining, iron and steel etc. And with our product can increase the using life 3-4 times, reduce the cost of maintenance and save downtime. As well as the company have passed IOS9001, SGS, IAF. The products are exported to South Korea, Mongolia, Peru, Australia etc.Production Process Wodon flux cored welding wire's advantage 1. Wire feeding smooth, electric arc is stable, the diameter is even.2. The welding wire has small spatter, little dust and more than 90% deposition efficiency.3. Each barrel (package) welding wire is a whole welding wire, without joint. The welding process has no arcing phenomenon and improves production efficiency.4. For the metal wear field, independently developed more than 100 kinds of flux cored wear resistant welding wire, can meet a variety of working conditions, parts of the wear-resistant requirements;5. The matrix and the wear-resisting layer are the metallurgical combined, and the welding does not fall off after welding, and the stress is released evenly after the surfacing.6. Provide qualification certificate, product specification, surfacing process, composition and hardness test report of surfacing layer, etc.Welding wire Workshop Welding Wires WarehouseApplication Area WODON wear plate and flux cored welding wires widely used for kinds of industry field: Dredging, Mining, Steelworks, Refineries, Cement, Timber, Power Generation Plants, Earthmoving, Coal Power Plant, etc. The steel manufacturing industry, for example, requires wear protection for hoppers, conveyor liners quickly erode without hardfacing protection. And coke injection line elbows, alloy hopper, reverse fan box, dust handling system, high blast furnance coke screens, replaceable ID fan housing liners, wood pulp transfer line, log stacker fork liners, 1/2'' on 1'' mill feed chute liner, flat back elows. As below is some examples of welding wire repairing : Coal grinding roller surfacing welding wire; Vertical cement mill surfacing welding wire; Squeeze roller surfacing welding wire; Repair welding wire for middle trough of coal mine; Roller surfacing welding wire; Repair welding wire for steel slag grinding roller; Repair welding wire for star wheel; and other repair welding wire. Various kinds of gas protection repair welding wires (repair all kinds of wear-resistant parts), high temperature resistant welding wire, grate bar and single tooth roller repair welding wire, impact resistant welding wire and various welding wires containing special elements (which can be customized as required)Customer Customer visit our factory FAQQ: Are you trading company or manufacturer ?A: We are factory.Q: How long is your delivery time?A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.Q: Do you provide samples ? is it free or extra ?A: Yes, we could offer the sample for free charge.Q: What is your terms of payment ?A:30% T/T in advance ,balance against copy of BL.

Company Profile

Jiangsu Wodon Wear Resistant New Material Co., Ltd.

Jiangsu Wodon Wear Resistant New Material Co., Ltd. (China Wodon) is a manufacturing factory specializing in the development and production of wear resistant materials. We are headquartered in Jiangsu. There are over 500 staff, including 60 experienced R&D engineers. Our main products include: chromium carbide overlay (CCO) wear plates, flux cored hardfacing welding wires, etc. With independent intellectual property rights and a number of patents, it has a strong R&D and debugging team, which can provide customers with a streamlined service.Since its inception, with the huge investment and independent technology research and innovation, Wodon has been taking the lead in providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the wear resistant industry as the company's technical consultant to ensure strong technical strength and production capacity, we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.

View more

>>

Alsafe 300bar Carbon Fiber Sports Scba Tank Sizes for Sale

>>

Vvvf Personalization Fully Variable Drive Mode Factory 0-35 Angle Outdoor Escalator

>>

Ultraviolet UVC Sterilization Corn Lamp 60W 20W 15W Office / Home Ues

>>

Disposable surgical face mask 3ply PPE BFE 99% 3 Ply medical disposable face mask

>>

Acrel Adw310-Hj-D10-4ghw Wireless Energy Meter Electricity Meter with WiFi Iot Platform Iot Watts Clever Wireless Energy Monitor

>>

Agricultural Farm Portable 1.4kg Light Weight Tea Plucking Machine

>>

Frozen food dumplings buns hamburgers mochi automatic flow wrapper pillow packing machine

>>

Advanced Design Bottle Filling Capping Machine for Liquid Makeup Foundation

>>

Nextool New Pocket Tool E1 Camping Outdoor Gear Multi Tool

>>

Newly Developed Rapid High Cut Speed Diamond Wire Profile Shape Contour Cutter Machine for Green Ceramic and Graphite, Paper, Gray Board Cutting

>>

High Quality Plastic HDPE PP Bottle Jerrycan Extrusion Plastic Jerry Can Production Blow Molding Machine

>>

pine laminated lumber lvl wood stud for house for Australia Market

>>

Costume Jewelry Earring 925 Silver Earrings Fashion Fine Bridal Jewellery (SNE2361)

>>

Premium Outdoor Barbecue Oven for Perfect Cookouts Anytime

>>

395mm Round Porcelain Wash Bathroom Basin Faucet Furniture Art Ceramic Sink

>>

Custom OEM CNC Mechanical Parts

>>

Ajmtg 3-5 Axis Graphite CNC Milling Machine

>>

Wholesale A3 A4 A5 330mm Roll To Roll Small Lamin Thermal Flatbed Table Mini Mica Para Plastic Photo Laminator Machine

>>

High Security Rustproof Mailbox Residential Wall Mount Metal Letter Box Parcel Postbox

>>

New High-Speed Multifunctional Computer Numerically Controlled Programmable Computerized Cap Flat and Garment Embroidery Machine