|

US$20,600.00-56,000.00

|

1 Set

(MOQ)

|

Basic Info.

Model NO.

PC4008-75/PC4012-90/PC4015-132/PC4012-90L

Theory

European Version of Coarse Powder Grinding

Application

Chemical Industry, Construction

Structure

The Top and Bottom Parts

Diameter of The Rotor

900

Length of The Rotor(mm)

1200

Rotation Speed of The Rotor

800-1000mm

Trademark

Luqiao mining machine

Product Description

How It Works

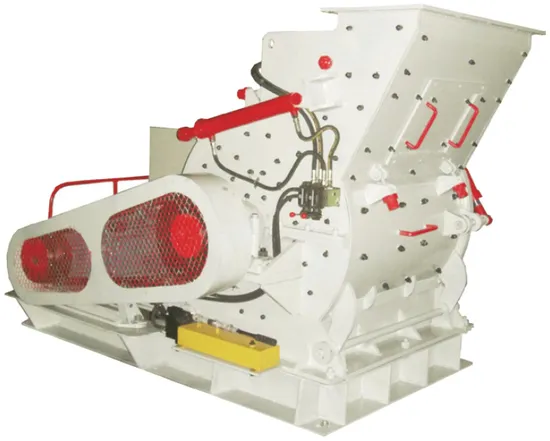

The European version of the coarse grinding mill is mainly composed of parts such as the shell, rotor, impact iron and bar. The shell is divided into upper and lower parts, which are welded by cutting high-quality steel plates; the remaining parts are bolted together. The crushing cavity is inlaid with a high-manganese steel lining plate, which is easy to replace after wear; an array of wear-resistant plate hammers with uniform weight is installed on the spindle rotor, and the wear-resistant plate hammer is fastened by high-strength bolts.

The mainframe drives the spindle through the motor and triangular belt, so that the rotor on the spindle rotates at high speed. After the large material enters the crushing cavity from the feed port, it is broken by the high-speed moving wear-resistant plate hammer. The qualified materials for crushing are discharged through the gap of the lower strip. The unqualified materials are left in the crushing cavity and repeatedly hit and crushed by the wear-resistant plate hammer on the rotor until they meet the standard and are discharged from the gap of the lower strip.

In order to avoid blockage of crushed materials, the water content of crushed materials generally does not exceed 20%.

Application Scope and Use of Coarse Grinding

1.) Application scope

Coarse grinding mill is mainly used in these areas, such as metallurgy, building, chemical, mining industriy, etc. It can grind a variety of non-explosive and non-flammable brittle mining materials, whose Moth's hardness is below 9 grade, such as quartz, feldspar, calcite, marble, porcelain, ironstone, copper ore, coal gangue, phosphate ore, granite, basalt, carborundum, corundum, heat insulating material and so on.

2.) Usage

Generating station to desulfidation: according to client's need, coarse grinding mill could be equipped with vibrating screen and could grind limestone into fine powder below 2mm or 1mm.

Quartz sand (silica sand, casting model powder, etc.): the fine sand from 0mm to 3mm can reach to 70% of the product.

Coarse powder mill: if it is used as coarse powder mill before ball mill, this machine can increase the efficiency of the ball mill by 50%.

Firebrick, baking-free brick, building blocks: the powder produced by this machine is the best mixture material for making baking-free brick and hollow building blocks.

Coarse powder: Equipped by vibrating screen, this machine's volume of production can be increased, 130-140% higher than normal Raymond mill.

Technical Features of Coarse Grinding

1.) It serves several purposes: this machine can produce the materials of various particle sizes after it constitutes the closed production line with auxiliary equipments.

2.) High efficiency: its efficiency of producing powder and fine sand is higher than ball mill, Raymond mill, vertical mill, etc.

3.) High operating factor of the abrasive materials: even wear of the plates avoids the trouble that rolls must be changed when the middle is sunken in the Raymond mill.

4.) Low fault rate: the special plate structure and seal make it more stable and longer service life than Raymond mill.

Technical Specification

| Model | PCW4008-75 | PCW4012-90 | PCW4015-132 | PCW4012-90L |

| Diameter of the rotor(mm) | 750 | 900 | 1150 | 930 |

| Length of the rotor(mm) | 800 | 1200 | 1500 | 1410 |

| Rotation speed of the rotor(r/min) | 800-1000 | 800-1000 | 550-800 | 800-1000 |

| Feeding opening(mm) | 320×930 | 400×1200 | 500×1500 | 380x1450 |

| Max. feeding size(mm) | <30 | <40 | <50 | 30-50 |

| Max. output size(mm) | 0-3 | 0-3 | 0-8 | 0-3 |

| Capacity (t/h) | 5-25 | 15-40 | 40-100 | 30-80 |

| Motor Power(Kw) | 75 | 90 | 132 | 55/75x2 |

| Dimension (L*W*H/mm) | 2310*1665*1610 | 2840*2100*2020 | 3720*2650*2540 | 3000x2600x2070 |

Note: All the technical data are subject to change without prior notice

>>

Black Half Finger Copper Infused Carpal Tunnel Arthritis Compression Gloves For Pain

>>

Revhon Singe Head Embroidery Machine Computerized T-Shirt Embroidery Machine

>>

Single Telescopic Ladder with Anti-slip Cushion

>>

Loading Rack Folding Stairs at Petrochemical Plant

>>

Jacket Hanger Coat Hanger with Pant Bar Wide Shoulder for Man and Woman

>>

Small Mobile Coal Crusher Machines Price for Calcium Carbonate Gypsum Limestone Quartz Graphite Calcite Feldspar Barite Fluorite Powder Production Line

>>

Floor Aluminum Steel Checkered Plate

>>

Cheap ink inkjet printers, date inkjet printers

>>

Aluminium double glass casement window glass price aluminum profile window casement window

>>

Automatic Fast Speed Feather Jacket Weighing and Filling Machine with Twelve Weighing Units (R2-12)

>>

Standard Lifeguard Torpedo Rescue Buoys

>>

DS200PCCAG6ACB

>>

Custom Designed Stainless steel Strap Set Apple Iwatch Series 6 7 Metal Phone Case Fashion Case For Apple Iwatch

>>

Professional Cereal Maize Rice Quinoa Buckwheat Drying Dryer Machine

>>

New Type Deyu Patent 160L Banbury Mixer

>>

Small Fields Gasoline Engine Power Tiller Reaper Agricultural Paddy Rice Cutter Harvester

>>

MDF Door Positive and Negative Pressure Vacuum Laminating Machine Vacuum Laminating Machine

>>

1-Eco-Friendly Recycled Polyester Fabric 4 Way Stretch Recycled Ocean Plastic Fabric for Tablecloth

>>

Galvanized Rectangle and Oval Cam lock for Access Door Accessories

>>

ERW Jp-165 High Frequency Carbon Steel Pipe Production Line Machines for The Production of Air Ducts