|

US$800.00-3,000.00

|

1 Set

(MOQ)

|

Basic Info.

Paper Core Usage

Paintings Packaging, Instrument Package, Industry

Tube Machine Type

Bending Machine

Layers of Roll Paper

9 - 16

Reelpipe Speed

6 - 12m/minute

Wall Thickness of Paper Tube

5 - 10mm

After-sales Service

Warranty

Inner Diameter of Tube

30-200 mm

Transport Package

Wooden Case

Specification

Make to order

Product Description

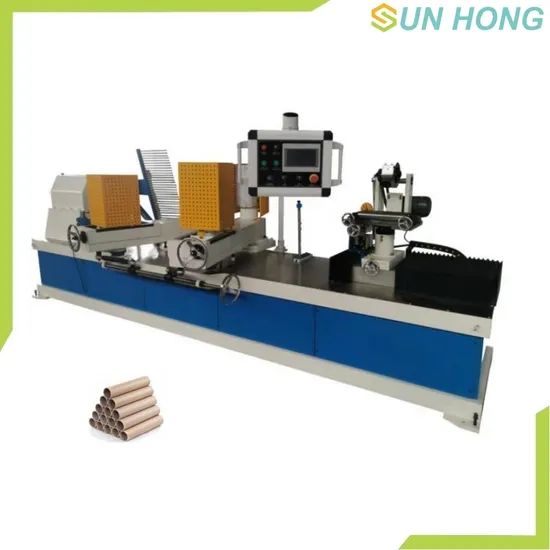

Paper Tube Making Machine

Final product: Cylindrical paper tube Raw material:Bobbin paper, kraft paper, white glue

Technical Parameter

| Inner diameter | ¢35mm-¢200mm |

| Thickness | 2-20mm(It varies according to the number of dense layers and the thickness of the paper) |

| Production speed | 0-20m/min(The speed is different due to the problem of paper tube specification and paper quality) |

| Cutting length | 500mm-4000mm |

| Main motor power | 15Kw |

| Working air pressure | 0.6Mpa |

| Fixed length mode | Infrared / encoder |

| Cutting motor | 0.75Kw |

| Gluing system | GT type |

| Paper holder | SZ type |

| Operator | 2-3 persons |

Main Function

A. Microcomputer length setting and accurate cutting length are adopted: the touch screen is convenient to adjust the data.

B. It adopts man-machine interface, special operating system and hanging operation panel, which makes the operation easier.

C. The paper strip tension control cutting system consists of an air pressure system, and the air cylinder compresses the paper strip, and its tightness can be adjusted at will.

D. 30 pieces of paper for gluing, including gluing box and pneumatic tension control, can be glued on both sides or on one side according to the strength requirements of the paper tube.

E. Mechanical paper feeding increases efficiency, reduces production personnel and reduces production costs.

F. The flange shaft is designed to be retractable, and the inner diameter of the paper tube can be fine tuned with the taper mandrel.

G. The transmission adopts frequency conversion speed regulation motor to adapt to the production of paper tubes with different requirements.

H. When the inner paper breaks, it can automatically alarm and stop the machine, so as to avoid sticking the mandrel with white glue.

I. The paper tube cutting part is controlled by the moving servo motor, which can track the production speed of the paper tube to achieve synchronization.

J. The paper pipe is cut by high-speed saw.

>>

Automatic Plastic Tool Box Injection Molding Machine / Making Plant

>>

Natural drying Acid Etching Ink

>>

High Speed Automatic Sleep Eye Mask Cartoning Box Packaging Machine 100box/min

>>

23Colors Baby Girl Headband with pearl bow Toddler Solid Color Headwear

>>

Luxury Centrifuge Production Chemical Tools Machines Refined Salt Pusher Centrifuge

>>

SMT Siemens Board Servo Amplifie PC Board TBS200 00344205S04 SMT Spare Parts

>>

2019 Tobemac Brand 1 Bagger Concrete Mixer for Industrial Use

>>

Camshaft Position Sensor 37510-RNA-A01 for Honda HR-V Accord Civic

>>

Mj6128y Precision Sliding Table Saw Price

>>

2024 Hot Sale Hotman E250 Cylindrical Grinding Machine

>>

new trending 2022 mad fit shoes fitness slimming slim leg thin body slippers for indoor outdoor house home

>>

LED Clear Display Clinical Digital Thermometers Waterproof with CE

>>

Men′s Wool Cashmere Quarter Zip Leather Puller High-Neck Jumper Sweater

>>

The First Milk Powder 10% Immunoglobulin Grade

>>

Cow Split Leather Welding Cowhide Hand Safety Gloves For Construction

>>

Custom 3ply Breathable Non-Woven Elastic Earloops Disposable Face Mask

>>

Camping Travel School Collapsible Silicone Cups

>>

Squeeze roller hardfacing flux cored welding wire

>>

interior office door with tinted glass sliding window

>>

Professional custom printed food grade bbq sticks eco - friendly bamboo barbeque skewers