|

US$15,000.00-235,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Material Processed

Plastic Flakes

Computerized

Computerized

Certification

QS, ISO9001:2008, CE

Heating Method

Electricity to Heating Oil

Material Status

Powder, Pellets, Pieces, Scraps, Chips

Function

Improve Material Viscosity

Vacuum Degree

Less Than 1PA

Maximum Temperature

250°c

Working Time

26-32 Hours(According to Target IV)

Nitrogen

Necessary for Pet Scraps

Transport Package

Wooden Pallet and Film Cover

Specification

20m* 20m* 7m

Production Capacity

80 Set / Year

Product Description

Product Description

Raw material: Resin or recycled PET, PA6, PA66, PTT

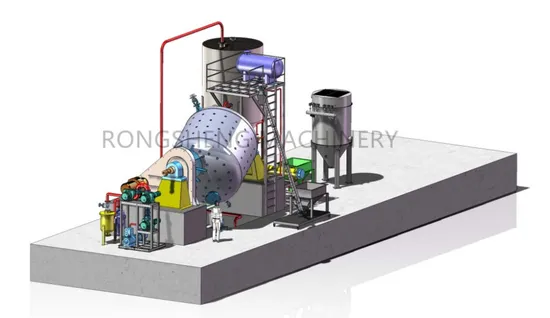

The solid state viscosity increasing device consists of: drum reactor, thermal oil heating and cooling system, vacuum system, electrical PLC (or DCS) control, etc.

And optional: automatic feeding and conveying, pre-crystallization system, automatic discharging and conveying, raw material dust removal and screening, nitrogen protection, etc.

The increase in IV(Intrinsic Viscosity) is based on the molecular characteristics of the copolymer. At the critical temperature, thanks to the special extreme vacuum technology and high-precision temperature control, small molecular weight chemicals will be extracted along with the vacuum pipeline and the copolymer molecular chain will be extended so that In order to meet the requirements of increasing viscosity, IV(Intrinsic Viscosity) can be steadily increased and high-purity and high-viscosity PET can be obtained, which can be used in spinning, industrial yarn, POY, FDY, packaging sheet, preform production and bottle-to-bottle recycling.

Product Parameters

Machine model: From 5 L to 46 cubes, Customized according to production capacity Out-put capacity: From 1Kg/ batch to 23000kg/ batch One batch time: 26 hours to 36 hours (Depends on target IV and original IV)

Detailed Photos

After Sales Service

It has a on-line system that can monitor customer process parameters and machine running at any time. When there is a problem with the customer's equipment, our company can quickly determine equipment problems and process problems through the on-line system. For some problems that cannot be solved by customers, our company will send engineers directly. Guarantee period and after-sales services:13 months since date of bill of lading During this guarantee period, Rongsheng will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, Rongsheng will provide the buyer spare parts at cost price. Long-term service: Rongsheng will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

Certifications

Installation Instructions

After all machines are delivered to customer's factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc. Rongsheng will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory. Engineer will give free training lessons to labors in buyer's factory. In some countries like India, Vietnam, we have local person who can go to customer factory for machine installation and testing.

Our Advantages

1. We are a original factory.

2. We have our own technical team

3. We can provide a complete set of solutions, SSP, LSP, washing and recycling machine, bottle to bottle, pelletizing machine.

4. We can provide upstream and downstream solutions, such as recycling equipment, granulation equipment, dryer, conveyor.

5. You can visit local equipment directly in some countries.

6. If you come to visit our company, we can take you to vist running machines in customers factory in China. To prove our company's professionalism and the good quality of our company's equipment.

Thanks, please email me.

>>

Hxm 98--3500 Servo Motor Energy Saving Plastic Injection Molding Machine

>>

Olive green deep cut custom cotton spandex gym tank top for men sports and training stringers superdry sport performance

>>

Coconut Tree Lights Palm Landscape Lamp Decoration LED Ring Light

>>

Anon Newest Hot Selling Automatic Groundnut Harvesting Bagging Machine Green Peanut Picker

>>

Crusher Chipper Machine Farm Industry Chipper 15HP Wood Chipper Wood Chipper 5 Disc Chipper Wood Electric Start Wood Chipper Drum Forestry Industry Chipper

>>

Ifan All Standard PVC Pipe and Pipe Fittings 1/2′′-2′′ Beige White Gray Green UPVC CPVC Fitting

>>

Wood Sander Dt1400-P6 for MDF Cabinet Door From Dtwmac Manufacturer

>>

Taijia concrete rebar scanner reinforced concrete rebar detector scanner and locator

>>

Hot Selling Promotional Genuine Leather Handbag for Women at Low Price

>>

SMS PP Spunbond Hg Melt Blown Non Woven Fabric Nonwoven Machine Hot Sale

>>

CH-JIA 20 Heads Flat Embroidery Machine Hot Sale

>>

Latex Gloves Powder Free / Disposable Food Prep Cooking Gloves / Kitchen Food Service Cleaning Gloves, bagease, bagplast

>>

4090 Nvidia High Performance GPU Liquid Cooling Module

>>

Shock absorber spring

>>

Computer Embroidery & Sewing Machine -Yinghe Brand

>>

Aluminum Ingot 356z.2 for Transfomer Industry Top Quality Direct From Chinese Manufacturers

>>

Florida Approved Large View Hurricane Impact Windows For Bathroom

>>

PET Release Film Transparent and Matte insulation film JB1256-77 Standard for industry use in roll

>>

Mayosperse 60 Polyquaternium-42 algaecide concentrated FOR swimming pool

>>

High-Quality Organic Fertilizer Pellet Machine for Efficient Production Granulation Equipment