|

US$15,000.00-300,000.00

|

1 Set

(MOQ)

|

Basic Info.

Computerized

Computerized

Certification

CE, ISO9001:2008

Customized

Non-Customized

After-sales Service

7*24hours

Electronic Parts

ABB/Siemens/Omron/Rkc

Voltage

380V/50Hz or Customizable

Transport Package

Seaworthy Packing

Production Capacity

500sets/Year

Packaging & Delivery

Package Size

6000.00cm * 2000.00cm * 2000.00cm

Package Gross Weight

8000.000kg

Product Description

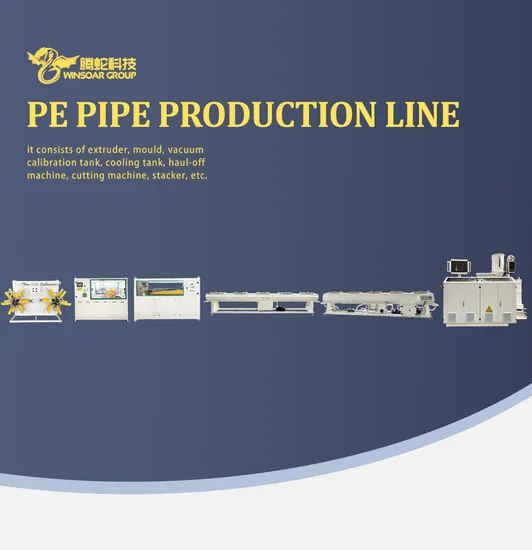

PE Plastic Pipe Extrusion Line is mainly used in the production of agricultural drainage, water supply and cable conduit purposes. The unit consists of single extruder machine, mold, vacuum forming tank, multi-claw haul-off machine, planetary(chipless/non-dust cutter) cutting machine, stacker and so on. And the line can be equipped with Comptroller thickening instrument or computer ink-jet/laser printer, etc. to achieve the production and manufacture of high-grade tubing.

Production Flow:

Material →Color Mixer →Material Feeding →Single Screw Extruder →Extrusion Mould & calibrator → vacuum Calibration Cooling Tank → Spray Cooling Tank →Printer → Haul-off Unit →cutter →stacker or Coiler

PE Pipe Extrusion Machine Features:

1. The optimum spiral bush highly improves the output of the pipe extruder

2. Accurate temperature control system ensures material melting performance

3. Unique screw design achieves better plasticizing and high-quality products

4. Precisely designed gearbox with a high torsion guarantees stable running

5. H sharp frame to decrease vibrating of an extruder

6. Advanced PLC operation system realizes synchronization and high-quality products

7. Adopt automatic water temperature &level control and special independent filters on both vacuum and cooling tanks

8. Offer a stable haul-off unit with 2-12 caterpillars

9. Provide saw &chip free cutting options

10. Low energy consumption, excellent performance, and easy maintenance

| 330 Series Classical Production Line |

| Diameter | Type | Max.Capacity(kg/h) | Max.Haul Off Speed(m/min) | Power |

| 20-63 | SJ65/33 | 220 | 12 | 55 |

| 20-110 | SJ65/33 | 220 | 12 | 55 |

| 50-160 | SJ75/33 | 400 | 10 | 110 |

| 90-250 | SJ90/33 | 400 | 6 | 110 |

| 160-450 | SJ120/33 | 500 | 4 | 160 |

| 400-630 | SJ120/33 | 850 | 2 | 280 |

| 500-800 | SJ120/33 | 850 | 2 | 280 |

| 315-630 | SJ120/33 | 850 | 2 | 355 |

| 500-800 | SJ150/33 | 1100 | 1 | 400 |

| 380 Series High Efficient Production Line |

| Diameter | Type | Max.Capacity(kg/h) | Max.Haul Off Speed(m/min) | Power |

| 20-63 | WSD60/38 | 320 | 30 | 70 |

| 20-110 | WSD60/38 | 380 | 20 | 90 |

| 40-160 | WSD60/38 | 460 | 15 | 110 |

| 50-250 | WSD75/38 | 600 | 12 | 160 |

| 110-450 | WSD90/38 | 850 | 8 | 250 |

| 250-630 | WSD90/38 | 1050 | 4 | 280 |

| 500-800 | WSD120/38 | 1300 | 2 | 355 |

| 710-1200 | WSD75/38 WSD90/38 | 1450 | 1 | 160/250 |

| 1000-1600 | WSD90/38 | 1900 | 0.6 | 280/280 |

The single screw extruder is simple in design and inexpensive, so it is widely used. It is suitable for extrusion production of PE, PPR, PERT plastic pipes, sheets and profiles.

The extruder is especially widely used on pipe production line to co-extrude pipe mark line. It is specially designed with lower power consumption and takes smaller space.

Used for shaping and cooling of pipes, it is equipped with a vacuum system, water circulation system, as well as front and rear moving device and left and right, height adjustment manual device, stainless steel box, circulating water spray cooling.

The cooling water is atomized and sprayed from the special nozzle after being pressed by the water pump, so that the product can be cool to 360 degrees in all directions.

It is used to continuously and automatically lead out the cooled and hardened pipes from the machine head, and the speed is controlled by frequency conversion.

After being controlled by encoder according to the required length, automatic cutting is carried out, the stacker is turned over with a delay, pipes are cutted smoothly without scraps and dust.

This machine is equipped with two reels alternately to ensure the continuity of production. It is suitable for plastic rewinding and packaging, automatic arranging, automatic rewinding, and easy operation.

Accept finished products and automatically turn over.

All Rights Reserved@ Winsoar Science& Technology Development Co., Ltd.

>>

Factory Price Wholesale Non-woven Coverall Jumpsuit Waterproof Overall For Person Protection

>>

(Cross border) Container Shipping From Japan/Korea/Taiwan to Kazakhstan/Uzbekistan/Turkmenistan/Tajikistan/Kyrgyzstan Via China

>>

Hot Sale Beef Bone Crusher Stainless Steel Bone Breaker Knives Crushing Machine

>>

3 Axis Vibration Meter VM-6380 for sale

>>

Best-Selling OEM Factory Bulk Multicolored Dried Papaya Dices for Export

>>

Titanium Rod Factory Direct Price High Strength Ta2 / Gr2 Pure Titanium Rod for Industrial 1kg

>>

Breathable White Anti Decubitus Latex Foam Bed Mattress

>>

Modern Hotel Gold Stainless Steel Dining Banquet Chair For Wedding Reception

>>

Energy Saving 5W 7W GU10 LED Bulb Spotlight

>>

Laser cut perforated metal mesh perforated metal facades

>>

High Polished Stainless Steel Aluminum Alloy Die Casting Fan Blades Axial Impeller for Screw Air Compressor

>>

Hot Selling in Southeast Asia CNC Cylindrical Grinder Machine Surface Grinder

>>

Professional DHL/UPS/FedEx China to U. S. /Global/Freight Forwarder

>>

Fully Automatic Mobile Lifting Platform Electric Lift Table 10m Elevator Scissor Lift Tables

>>

Factory direct sale High Quality 304 stainless Steel industrial plastic Granule storage buckets

>>

700kN Marine Electric Towing Winch

>>

High Performance Suspension Parts Trailing Arm Bush Suspension Control Arm Bushing 545844L000 54584 4L000 54584-4L000 For Hyunda

>>

LM339DT STMicroelectronics Analog Comparators Lo-Pwr Quad Voltage

>>

Metal Casting Parts-Alu Die Casting and Machined Parts (HS-ALU-007)

>>

Large Sized Heavy Duty Cutting Machine Lathe Cw61140c/4000