|

US$4,200.00

|

1 Piece

(MOQ)

|

Basic Info.

Molding Material

Metal Mould

Extrusion Mould

Hollow Mould

Nose Application

Profile Molding, Film Forming, Pipe Forming

Pressure of Nose

High Pressure

Non Metal Mould

Plastic Mould

After-sales Service

One Year

Product Description

| Extrusion | Extrusion |

| Nose Application | Profile Molding |

| Metal Mould | Extrusion Die |

| Extrusion Mould | Hollow Mould |

| After-sales Service | 1year |

| Trademark | PLASTEX |

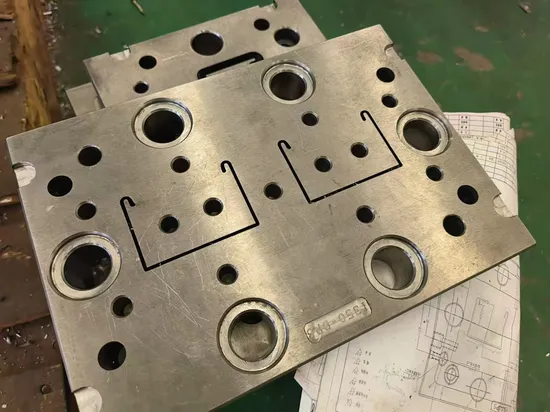

PLASTEX Extrusion Die Product Introduction

1. Product Overview

PLASTEX extrusion die is a high-performance mold product launched by MIC International Station, which is suitable for the extrusion process of various materials. Thanks to their superior design, precise manufacturing and reliable quality, PLASTEX extrusion dies are used in a wide range of applications in plastics processing.

Second, the use and characteristics of the product

Use:

Plastic pipes: Manufacture of plastic pipes of various sizes and sizes for water supply, drainage, gas transmission, etc.

Plastic sheets: Production of plastic sheets for construction, packaging, furniture, etc.

Plastic profiles: Manufacture all kinds of plastic profiles, such as door and window frames, decorative strips, etc.

Plastic film: production of all kinds of packaging film, agricultural film, etc.

Features:

High precision: Advanced manufacturing technology is adopted to ensure the accurate size of the mold and meet the high requirements of molding accuracy.

High wear resistance: The mold material is made of high-performance alloy, which has been specially treated to improve wear resistance and prolong service life.

Easy maintenance: The mold design is reasonable, easy to disassemble and clean, and reduce maintenance costs.

Wide applicability: suitable for extrusion of a variety of plastic materials, such as polyethylene, polypropylene, etc.

3. Rule parameters

Mold material: high-performance alloy steel, nitrided to improve hardness and wear resistance.

Mold structure: It is composed of positive mold, mold pad, mold sleeve and other parts, and the design is reasonable to ensure the stability and reliability of the extrusion molding process.

Mold size: Customized according to customer needs to meet the extrusion needs of different specifications and sizes.

Shunt ratio and extrusion ratio: Shunt ratio directly affects the extrusion resistance, forming quality and welding quality; The extrusion ratio is one of the important parameters to measure whether the profile is suitable for production on this extruder. The specific value is determined according to the mold design and customer needs.

Fourth, quality standards

Appearance quality:

The surface of the mold is intact, and there are no cracks, porosity, unevenness and unevenness.

The surface of the mold and the surface of the mandrel are highly matched, and there is no tilt, misalignment, deformation and other phenomena.

Dimensional accuracy:

The dimensions of the mold are strictly in line with the drawing design standards, including the overall size, the size of the key parts and the size of the fit.

The dimensional tolerances meet the technical requirements to ensure that the accuracy requirements can be met during processing and use.

Finish:

The surface of the mold is flat and smooth, free of holes and burrs.

After molding, there are no defects such as wear, scratches, twists and other defects on the surface of plastic products.

Processing and molding quality:

Plastic products are evenly stressed during the molding process, without warping, deformation and other defects.

Plastic products have excellent physical and mechanical properties, such as wear resistance, cold resistance, corrosion resistance, etc.

Other Criteria:

The mold material is made of materials with excellent performance to ensure the stability and wear resistance of the mold.

The hardness of the mold forming parts is not lower than the specified standard, and the heat treatment is sufficient.

The ejection mechanism is smooth, no stagnation, and no abnormal sound.

The cooling or heating system is fully unobstructed and the seal is reliable.

>>

Plastic Extruder PVC WPC Celuka Foam Sheet Board Extrusion Machine

>>

Heavy Duty Stainless Steel Garage Door Universal Safety Jamb Bracket

>>

Cheapest Promotional Gift Stylus Metal Ball Pen with Customized Logo Imprint

>>

High-Efficiency Resin Tile Extrusion Line

>>

Fashion Stock Linen Woven Plain Dyed Fabric for Garment-240009-67-68-69

>>

PCB Boards Recycling and Metal Recovery Plant, Recycle Precious Metals from E Waste

>>

Full Color HD 4K SMD Small Pixel Pitch P1.2 P2 P2.5 P3 P4 P4.81 P6.67 P8 P10 P16 Indoor Outdoor Rental LED Advertising Billboard Video Wall Panel Screen Display

>>

Black Custom Sublimation Jacket with White Zipper of 2022

>>

High Speed Double Line Cardboard Slotting Machine

>>

Andrographis Extract 98% Andrographolide

>>

Aluminum Alloy Heavy Duty Sliding Folding Door Hardware Hinge For Casement Door And Window

>>

Semi-Servo Specialized Baby Diaper Production Line with CE (YNK400-HSV))

>>

Module spare parts 5302-MBP-MCM4

>>

HAVEN brand Hydraulic Guillotine Shearing Machine Steel Plate Cutting Machine

>>

Industrial Garment Factory Straight Insert Sewing Center Table

>>

Hydraulic Reversible Furrow Plough Share Plow Moldboard Plough

>>

4m 6m 8m 10m 12m Aerial Work Platform Electric Aluminum Alloy One Man Single Mast Lift

>>

Acrylic Plastic Sheet Press Cutting Machine (HG-B30T)

>>

Good quality electric fat bike 500W 1000W new 2022

>>

Wooden Birdhouse Bird Cage for Pets Small Animals Outdoor