|

US$25,000.00-300,000.00

|

1 Set

(MOQ)

|

Basic Info.

Material Processed

Bottle and Film

Computerized

Non-Computerized

Production Name

Waste Plastic Recycling Machine/Line/System

Transport Package

Metal Base

Production Capacity

100PCS/Year

Packaging & Delivery

Package Size

650.00cm * 450.00cm * 230.00cm

Package Gross Weight

64000.000kg

Product Description

Product Description

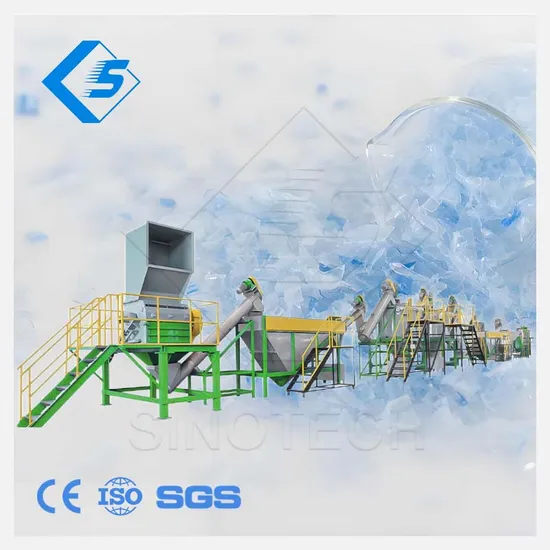

Plastic Recycling Washing Line

PET bottle washing recycling line is a full automatic crushing washing dewatering and drying production line, it is the ideal equipment to waste mineral water bottles, cola bottle, PET bottle sorting, label removing, crushing, washing, dewatering and drying machines.

Product Description:

1.This line is mainly used for recycling the waste PET bottle, PET container etc.

2. To separate PET bottles to flakes from label, cap, oil, garbage.

3. This line is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing system, etc.

4. Easy to operate, Full automatic.

5. Production capacity: 500KG/H, 1000KG/H, 1500KG/H, 2000KG/H, 3000KG/H

Main Advantage:

1. Automotive line for recycling the PET bottles and other waste plastic profile, except the film.

2. The final product is the cleaning flakes, if you want the final product is pellets, we should equip the granulator line again.

Features:

Capacity: 500-3000kg per hour

Moisture of PET Flakes: Less Than 2%

Cap &Label separate with the PET bottle flakes automatically

Bottle Types: PET Bottle, Plastic Bucket, Water Bottle, Coke Bottle,

Application: PET Strap, PET Yarn Fiber, PET Sheet

Product Parameters

| Model | PET-500 | PET-1000 | PET-1500 | PET-2000 | PET-3000 |

| Capacity | 500kg/h | 1000kg/h | 1500kg/h | 2000kg/h | 3000kg/h |

| Total power | 180kw | 240kw | 350kw | 440kw | 653kw |

| Actual power | 126kw | 168kw | 245kw | 308kw | 457kw |

| Workers | 5-6persons | 7-8persons | 9-10persons | 11-12persons | 14-15persons |

| Water needed | 3-5t/h | 5-6t/h | 6-8t/h | 6-8t/h | 7-10t/h |

| Final production | Water content: ≤1.5%

Stacking density: 0.25-0.35 g/m³

Flakes size: 14mm (according to customer request)

Fine granule: ≤ 3%;

Powder: ≤ 5% |

Detailed Photos

The production line includes: De-baler, belt conveyor, trommel, label remover, sorting table, crusher, floating washing tank, screw feeder, hot washer, high speed friction washing machine, centrifugal dewatering machine, dryer blower and label seperator, silo, electric cabinet etc.

01 Metal chain conveyor

Usage: Cut the bundled PET bottles of wire, through the chain conveyor to the unpacking machine unpacking

02 De-baler

Usage: Manully cut off the packaging steel line of the packaged bottles. then put them into the debaler. The packaged bottles will opened by the running screw blade and run ahead to exit.

03 Trommel

Usage: Separate different impurities such as sand, rocks ,metals, caps according to different size of the holes

04 Label-remover

Usage: for removing the labels by friction between screen and arms

05 Platform of choosing color bottles with metal detector

Usage: Manually separate any impurities that can be seen.

06 Wet crusher

Usage: to crush PET bottles into PET flakes.

07 Floating washing tank

Usage: to remove labels, caps chemicals dirties etc

08 Hot washer

Usage: for wash with hot water and detergent to get rid of oil, dirties and some labels

09 High speed friction washing machine

Usage: through the injection of high pressure water, the effective remova of chemicals and impurities

10 Centrifugal dewatering machine

Usage: to get rid of glue, dirties, oil. detergent and etc.

11 Zig-zag label blower

Usage: to separate labels and dust from the flakes.

productive process

Company Profile

Certifications

Packaging & Shipping

FAQ

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon.

Q: Do you provide any spare parts with machine?

A: Yes, we offer all necessary spare parts together with machine sending and 3 days spare parts delivery after machine sale.(contact us for packing list )

Q: How about your after-sale service?

A: We offer manual instruction and engineer training before loading, after shipment we provide 24 hours online support, video technical support or field installation assist.

Q: What is the lead time?

A: We have standard model machine in stock.It can be delivery within 1 week. If need to make mould, the delivery time need half month after drawing confirmed.

Q: What is the warranty period for your machine?

A: 12 months warranty for components and technical support.

Q: Do you provide custom machines?

A: Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: What's the advantage of SINO-TECH?

A: We provide customers with turnkey projects. Including plant design, blow molding machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time for customer.

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon.

>>

White or Gray PVC Compound for PVC Fitting

>>

Waste Agriculture Film Recycling System Industrial Film Washing Line

>>

Dd703 Series High Speed Micro Hole Drilling EDM Machine

>>

Custom Logo High Quality Ultra Soft PBT Bristle Plastic Manual Kids/ Children Toothbrush for Sensitive Teeth

>>

7.62/5.56/12.7/14.5 Gilding Metal Clad Steel Bimetallic Composite Bullut Case Cartridge Cups

>>

Nurse Paramedics Doctor Emergency Healthcare First Aid Kit Trauma Medical Bag

>>

3A USB C to USB Type C Cable Quick Charge 3.0 100W PD Fast Charging Mobile Phone Charging Type-C Charger

>>

Musical Instruments Noise Maker Small Metal Cow Bells Custom Cowbells

>>

Waste Plastic Films Wash Dry Clean Line for Plastic Recycling Machine

>>

6T-40T Strong High Rigidity Heavy duty Lathe

>>

Chic Brown Button-Detail Crop Fashion Sweater for Women

>>

600*600*2mm 3mm Anti Static Homogeneous ESD Tiles for Electronics/Clean Room

>>

UNITROL5000 ABB module supply

>>

HDPE LDPE Film Plastic Agglomeration Machine/Compactor Agglomerator Recycling Machine for Waste Film

>>

Shock Absorber Anti Vibration Custom Rubber Block Furniture Rubber Vibration Pad

>>

Galvanized expanded metal mesh 8*16mm

>>

Coil to Coil Grinding and Polishing Machine

>>

Turtle Bird Food Aquarium Shrimp Fish Feed Extruder Dog Cat Food Machine Line Plant

>>

LIVTER Free Shipping Cnc Router Bits With Replaceable Carbide Inserts Straight Cutter For Trimming Wood

>>

New Wireless Waterproof Remote Controller (YK-11)