Basic Info.

Plastic Type

Thermoplastic

Plasticizing Way

Screw Type

Computerized

Computerized

Injection Rate (G/S)

789 G/S

After-Sales Service Provided

Engineers Available to Service Machinery Overseas

Video Outgoing-Inspection

Provided

Injection Weight (G)

3574 G

Key Selling Points

Competitive Price

Core Components

Bearing,Motor,Pump,Gear,PLC,Enginescrew

Place of Origin

Zhejiang, China

Plastic Processed

Pppchdpepe,HDPE/Ppabs/Pppe/PP

Product Description

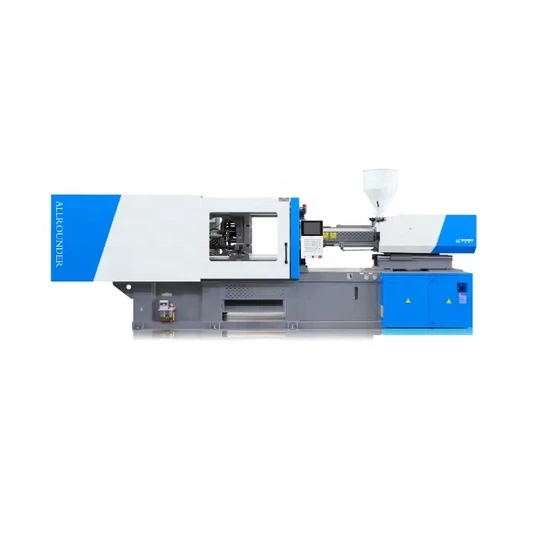

Haichen HCK800 ton injection molding machine plastic container making machine plastic fish seafood crate turnover box for fruits

Product description

We specialize in plastic industry for more than ten years. Manufacturing plastic injection molding machine, moulds and auxiliary machines.Our plastic injection molding machine with clamping force ranges from 90ton-3000ton.Our machine works as high precision and rigidity. It has excellent performance, fast response and energy efficiency.

No.

| Item no. | Size | Raw material | Weight | Color | Cavity | Other |

|

| 1 | sea food

plastic crate

| 60*40*35cm | new or recycled PP/HDPE | 3-kgs | for select | 1 | without core

|

|

|

Remark: customized size order are accepted

We could like to share various kinds of plastic products manufacturing technology with our clients.We never compromised on the quality and have an excellent track records for the customer satisfaction.

CONTROL SYSTEM

|

| FEATURES:

• A variety of text can be switched.

• Manual,semi-automatic and fully automatic mode.

• To provide EUROMAP robot interface.

• Automatic movement monitoring with alarm and fault diagnosis.

• Function of slope setting can set the start and stop of movements,so as ensure the smooth movement.

• Screen protection function,prolong the life of screen using.

• Electrical motor safety protection device.

• Robotic pincher interface.

|

All-digital control system uses dedicated controller,multiple CPU processing division,a multi-functional automatic fault detection,alarm system,certificates 99 mold of processing procedures,with remote control interface.System is of high stability and responsiveness.System uses color LCD,man made interface for easy operation and with a number of peripheral interface.

|

INJECTION SYSTEM

|

FEATURE:

• APID temperature control, precise temperature control of barrel.

• There are three or four screws and barrels with optimal design, respectively, nitride, hard plating, dual- metal, which is suitable for different processes of variety of plastics. And the choice of product.

• Two -guided guided bar supports, double-balanced rapid injection.

• The high-torque hydraulic motors offer a stable plasticizing capacity, high-precision electronic device position detection enable accurate measurement.

| |

• Multi-injection speed and pressure and multi-level holding pressure settings, switch from the injection time, location, pressure control to ensure the quality of molding.

• Multi-level back-pressure of pre-plastic and pre-speed are computer-controlled, anti-drooling and automated auto purge.

• Expected to prevent cold-start function to ensure that the screw, barrel will not be harmed. Stability of the injection unit. |

CLAMPING SYSTEM

|

FEATURE:

• Security doors fitted with hydraulic, mechanical and electrical interlocking triple safety device. When the safety door is open, the machine cannot clamp.

• Low pressure mold protection device to prevent damage to platen.

• Plywood, frame, the bridge, and the template attached structure, the finite element analysis.

• Hydraulic ejector, adjustable stroke, and top speed of ejector in and out, for multiple actions.

• Flexible tie bars but eliminates fatigue fracture; assure the working life of tie bars.

| |

• Automatic adjustment. The replacement of different mold, the parameters set by clamping force to achieve the automatic adjustment.

• High-precision electronic detection device, multi-stage control of opening stoke, speed and location, location accuracy.

• Arch splint piece of the tail plate use the finite element analysis. It features as light weight, high-intensity, and high- rigidity.

• Flexible core programming control, and independent hydraulic pump station to provide power.

|

HYDRAULIC SYSTEM

|

|

FEATURES:

• The manual plug valve hydraulic system make the machine having quick and smooth motion response

• Double proportional valve control pressure and flowl

• Hydraulic oil cooling device

• High-performance imported hydraulic unit with optimizing allocation

• The fuel tank has a big opening hole so can be cleaned easily

|

ADVANCED HYDRAULIC SYSTEM DESIGN through proportional control of pressure,flow achieves rapid multi-level pressure,speed switching,the system configuration is reasonable,stable and reliable.The noise is less than 75dB.The medium and large machine adopts a two-way cartridge inserted valve system to improve the system of flow and speed of response, and makes the whole machine reach the best performance.

|

| SAFE SYSTEM |

|

• The safety devices include safety door and locking-self mechanism.All safety doors are very important to avoid personal to damage by splashing melted material and prevent person from dangers zone.The locking-self mechanism will stop all damage action at any door opening.

• The safety door limit switch serves to interrupt the mold closing.When the safety door is open,limit switch has been activated to brek the circuit.Its dual circuit control functions of Normally closed and Normail open can stop the motion of the machine.

|

In case of any accident or error in the process of operation,first press the emergency stop button (the red projectied one on the lower right corner of the screen),and then turn off the main power supply switch.Find out the causes of fault and do not start the machine until all faults have been rectified.

|

About us

HC series plastic injection molding machine has moving platen featuring box type bridge structure and full-connected rear high-rigidity mold platen. Through finite element analysis, it can prevent deforming of mold platen, resist against fatigue, have high repetition accuracy, distribute mold closing force uniformly, greatly increase mold's service life and reduce the molded parts cost.

Clamping unit:

1. Internally-rolled 5-point double toggle mold clamp structure, greatly increases rigidity and precision of the mold clamp unit.

2. With box type bridge structure, moving platen, and high rigidity continuous rear platen reinforced through finite-element analysis, we guarantee that the mold platens are not deformable and are durable.

3. The tie rods are made of high quality structural alloy steel plated with hard chromium, with high mechanical strength and fatigue strength.

4. Provided with low-pressure mold protection device.

5. Multi stages controlling of mold clamp pressure, speed and position.

6. Mold thickness adjusted through ring gear driven by hydraulic oil motor.

7. Several hydraulic ejection modes.

Injection unit:

1. Use of double guide posts and dual-cylinder balance injection device, guarantees that balanced and uniform forces are applied on the screw during injection and moving forward.

2. High quality alloy screw nitride or with chromium plating, and nitride barrels, are protected against corrosion and fatigue, which greatly increase their service life.

3. With fine adjustment of nozzle centering.

4. Screw preplasticizing driven by high torque hydraulic motor device.

5. Multiple injection speed, pressure and position settings.

6. Special screws and barrels are provided according to different properties of engineering plastics to ensure the molding quality of finished products.

Lubricant unit:

1. With use of volumetric electrical lubricator, automatic centralized lubrication and uniform oil distribution in the pipeline, the machines have high lubrication efficiency and long toggle life. Hydraulic unit:

1. Well-known oil pump and control valves in the world are used, to execute accurate controlling over the force, speed and direction of hydraulic mechanism and ensure the accuracy, reliability, stability and durability of the machine.

2. Control system of the constant displacement pump ensures steady outputs and high response.

3. Main hydraulic elements and seals are international well-known brands.

4. The pipelines are arranged more reasonably and better, and thus ensure easy maintenance.

>>

3TPH DEF Diesel Exhaust Fluid Plant Use RO Water Purification System

>>

SBW-F Series Three Phase 380V 400V 500~1000kVA AC Automatic Voltage Regulator Stabilizer

>>

Moving Shipboard Crane Geming Op 54 Waterproof Electric Lifting Column

>>

custom logo print sports mens tank top sleeveless travel vest gym tank top

>>

Kids Play Center, Softplay Children Amusement Park Indoor Playground Equipment Shopping Mall Amusement

>>

530 Engine Gasoline 4 Stroke Petrol Grass Cutter

>>

Food Container Fast Food Box Plastic Sushi Tray with Anti Fog Lids

>>

2019 women outdoor touch screen monitor ce rohs heart rate monitor ip67 waterproof smart watch

>>

Hsh Series Swing Beam Shearhot Selling High Precision Shearing Machine

>>

Sprinkler Fire Fighting System Fire Sprinkler Fittings

>>

Zr 2025 New Factory Price Best Rest Wireless Portable Multi-Function Time Constant Temperature Hot Compress SPA Waist Neck Hip Foot Leg Back Massager

>>

L.A. Abrasion Test factory price

>>

High strength drill tail screw

>>

Wind Solar Hybrid Power System /Wind Turbine /Solar Power System (700W) Wind Generator System for Home Use Wind Power Wind Mill Solar System

>>

High Speed Steel Titanium Step Drill Bits

>>

Black Galvanized Steel Perforated Wire Metal Sheet Speaker Grille

>>

High Altiture Agricultural Large Capacity Drones Spraying Drone 22L

>>

LOREADA Carby carb carburettor CARBURETOR ASSY for SUZUKI SJ410 engine 13200-80322 13200-80321 1320080322 1320080321

>>

Metal Laser Cutting Machine Laser Cut Industrial Machinery Equipment for Plate and Sheet

>>

Free Shipping EPA/Euro 5 Engine Chinese Big Excavator 60t 32t 23t 18 Ton 15 Ton Wheel Excavator Cabin Digger Best Price for Sale