|

US$150,000.00

|

1 Set

(MOQ)

|

Basic Info.

Plastic Processed

Polystyrene

Product Type

Extrusion Molding Machine

Assembly Structure

Separate Type Extruder

Engagement System

Full Intermeshing

Screw Channel Structure

Deep Screw

Computerized

Computerized

Sheet Width

Double Sheet 1300mm

Transport Package

Standard Packaging

Production Capacity

5sets

Packaging & Delivery

Package Size

4000.00cm * 450.00cm * 300.00cm

Package Gross Weight

32000.000kg

Product Description

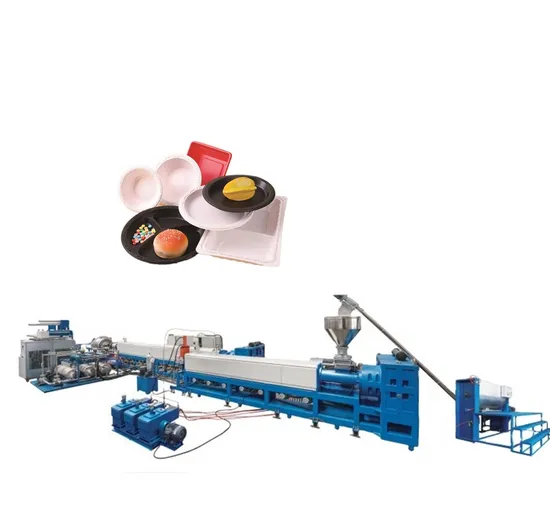

Description of Plastic sheet extruder machine sale

1.Production process

Expand Polystyrene Sheet Extruder is the sheet producing machine with 2 screws and by gas foaming type.

It takes General Purpose Polystyrene (GPPS) as raw material, injects gas foaming agent during the producing process. And the Winder wraps up the sheet in rolls.

2.Product use

The sheet is for thermoforming purpose, and can be made into fast food containers, egg trays, disposable bowls etc. Since it has properties of heat and sound insulation, the sheet material is also widely used in architecture; such as decorative board, inner ceiling of car.

3.Advantages

1)Precise strong screw

2)Precise elements

3)No leakage

4)Parts brand we use:Mitsubishi, Siemens, Lewa

5)Even thickness and smooth sheet

6)Can save all kinds of technical parameters

7)PLC control

MODEL PROVIDED

4.Technical Parameters

| Foam Polystyrene Sheet Extruder Main Techincal Parameters |

| Style No. Parameters | Unit | HLSJPS-120/150 | HLSJPS-100/130 | HLSJPS-130/170 |

| Capacity | kg/hr | 370-500 | 250-310 | 450-550 |

| Thickness | mm | 1.2-6 | 1.2-6 | 1.2-6 |

| Width | mm | 1000-2000 | 1000-2000 | 1000-1500 |

| Foaming Ratio | times | 11-30 | 11-30 | 12-25 |

| Linear Speed | m/min | 5-40 | 5-40 | 5-40 |

| Mounted Capacity | kw | 540 | 250 | 625 |

| Pressure of Cooling Water | mpa | ≥0.2 | ≥0.2 | ≥0.2 |

| Cooling Water | t/h | 18 | 13 | 20 |

| Compressed Air Pressure | mpa | 0.7 | 0.7 | 0.7-0.9 |

| Compressed Air Amount | CBM/min | 1.5 | 1.1 | 2 |

| Butane Injection Pressure | mpa | 1 | 1 | 1 |

| Weight | ton | 22 | 18 | 32 |

| Installation Size | m | 35*4.55*3 | 33*5*3 | 40*4.5*3 |

5.After sales Service

1)We dispatch engineers to customers' factories for installation and training.

2)One year warranty for main machine parts, and after one year we supply parts in reasonable price

3)24hours on-line service for you.

6.Photos

>>

C1 125X9mm Close Type Drop Wires Dropper for Textile Weaving Loom Accessories

>>

Fashionable Customized Singlet of Good Quality Design for Woman

>>

Smart Fixed Gas Monitor Fixed Ozone Gas Detector Fixed Methane Sensors Combustible Gas

>>

High Class Catalyst CO2 Laser Tube-Prh Series (PRH-2000)

>>

OEM/ODM R410 T1 T3 Air Conditioner Inverter 24000 Btu

>>

Hydraulic Metal Plate Bender Automatic Matal Bending Machine CNC Press Brake

>>

HC-L033 High Quality Portable dental integrated turbine dental instrument rod treatment machine/portable dental turbine

>>

Personalised Logo 3D PVC Rubber Souvenir Fridge Magnet

>>

1874120M91 Massey Ferguson Tractor Ignition Switch

>>

2022 Professional Scar Removal Skin Resurfacing Co2 Fractional Laser Co2 Fractional Co2 Laser Portable

>>

Rompi Pendingin

>>

Disposable level 1 level 2 PP SMS PP+PE laminated Isolation Gown dental isolation gown

>>

Customized Grocery Store Shelving Shop Retail Display Stand Racks Supermarket Wooden Shelf

>>

BPA Free Anti Slip Fiberglass Mesh for Silicone Perforated Mesh Mat Liner

>>

Custom Ultralight Tr90 Polarized Outdoor Sports Glasses UV400 Men Fishing Sunglasses for Drive Car

>>

YTK-X5S New Stainless Steel Household Oil Press For Soybean With Temperature Control

>>

Customized Res-Tdp5 Single Punch Press for Effervescent Tablets Making

>>

LED Grow Light UV IR Full Spectrum Samsung Lm301b Lm301h Grow Light Bar 680W 640W 600W Dimmable Growing Light LED Indoor Plants

>>

Cash Register Thermal Paper Roll for POS ATM 57mm

>>

Pile Integrity Testing Services - PIT