Product Details

Product Description

Product Description

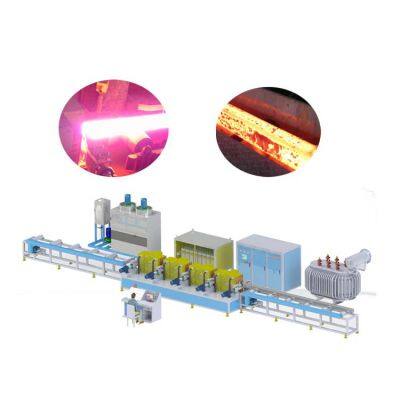

Main technical parameters of steel billet hot rolling heating furnace:

● Applicable workpieces: Suitable for pre rolling heating of steel billets, square billets, square steel, continuous casting billets, slabs, etc.

● Power supply system: Dual rectifier 12 pulse or 24 pulse 1000-12000KW/500-1200Hz, single power supply can be used independently or multiple power supplies can be used in parallel; The hourly output is 40-300 tons.

● Applicable range: 120mm~160mm square billet, length 3000mm~12000mm.

● Feeding system: Each axis is driven by an independent motor reducer, with multiple axis drives set up and controlled by a single frequency converter to synchronize the operation of multiple axes.

● Guidance system: using 304 non-magnetic stainless steel guide wheels, and maintaining moderate elasticity in the axial direction of the guide wheels to adapt to the allowable bending range of the steel billet.

● Temperature closed-loop system: A closed-loop control system composed of Leitai infrared thermometer and Siemens S7, which automatically adjusts the power supply according to the initial temperature and feed rate of the steel billet entering the sensor, so as to maintain a constant heating temperature before it is discharged from the furnace.

● Energy conversion: Depending on the surface temperature of the steel billet, the power consumption per ton of steel is 40-60 degrees

Advantages and characteristics of steel billet hot rolling heating furnace:

●If a steel billet hot rolling induction heating furnace is used in the steel billet hot processing workshop, the workshop temperature is greatly reduced due to less heat loss, which improves the working conditions in the workshop. Due to the fact that the induction heating process for hot-rolled steel billets does not produce smoke or dust during the processing of workpieces, it purifies the working environment of the workshop and meets the requirements of energy conservation and environmental protection in the new era.

●In terms of electric heating for production equipment, resistance furnaces are rarely used for heating raw materials before hot forming because the heating temperature of the raw materials is relatively high and limited by electric heating elements. Therefore, induction heating is mainly used. Induction heating of raw materials before hot forming has been used in processes such as forging, hot stamping, hot extrusion, and hot cutting of raw materials.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

>>

170f Gasoline Engine 7.0HP Cultivator Manual Starter, Recoil TM-Wg1000 Mini Tiller

>>

China excavator attachments auger

>>

1-3/4" Wooden Carpet Gripper Rods Tackstrip for Carpet Installation

>>

Yarn Guide Hook for Circular Loom Textile Knitting Machine Spare Parts

>>

Olive Oil Glass Bottle in Stock Green, Dark Green, Brown, Round, Square Shape FDA, EEC, LFGB Certificated

>>

Trailing Offset Disc Harrow

>>

Custom Logo Metal Gold Plating Brooch Enamel Hat Lapel Pins

>>

PVC, PE, PP, PC, TPU, EVA Plastic Pulverizer

>>

Marya Pharmaceutical Industry Vial Liquid Washing Filling Stoppering Capping Machine Vial Bottle Filling Production Line with Sterile Isolation System

>>

100mm 10bar General Pressure Gauge G1/2

>>

factory price plastic PVC honeycomb sheets cooling tower fill packing

>>

Fast Drilling M14 Porcelain Tile Bit Ceramic Drill Bit with Wax

>>

S5735-S Standard Gigabit 10/100/1000base-T Ports Enhanced Layer 3 Ethernet Switches

>>

Juicer Motor Blender Universal AC / DC Motor

>>

Infusion chair

>>

Solid Color Portable Leather Pen Protective Case

>>

Cement-based osmosis crystallization waterproof coating bathroom roof basement wall pool moistureproof leakage plugging

>>

Water resistant wind resistant breathable women's jacket

>>

First Class Tungsten Beads Tungsten Countersunk Round &Slotted Beads

>>

Fuel Injection Test Equipment Hpi/Smart Injector/Eui High-Pressure Fuel Test Bench