|

US$3.30

|

10,000 Pieces

(MOQ)

|

Basic Info.

Material

Alu-Zinc Steel Plate, Sand Chips

Certification

Follow The Order

Special Design

Can Be Developed

Transport Package

Wood Pallet

Specification

110 X110X120CM

Production Capacity

100000

Packaging & Delivery

Package Size

110.00cm * 110.00cm * 120.00cm

Package Gross Weight

1800.000kg

Product Description

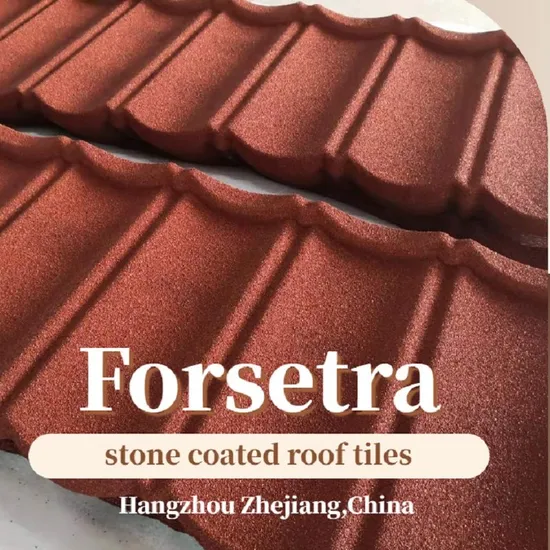

Product DescriptionA Stone Coated Metal Roof Tile is a high-performance roofing material that combines the strength of galvanized or Al-Zinc (Galvalume) steel with the beauty and durability of natural stone granules. These tiles are widely used in residential, commercial, and industrial buildings due to their waterproof, weather-resistant, and long-lasting properties.

Key Features & Benefits:

Waterproof & Leakproof - Prevents water penetration, ensuring a dry and safe interior.

Durability - Made from Al-Zinc steel, resistant to rust, corrosion, and impact.

Weather Resistance - Withstands extreme conditions such as heavy rain, snow, strong winds, and UV exposure.

Fireproof - Class A fire resistance, reducing the risk of fire hazards.

Lightweight & Easy Installation - Lighter than traditional roofing materials, reducing structural load and installation time.

Aesthetic Appeal - Available in various colors and profiles, replicating traditional clay tiles, asphalt shingles, or wooden shakes.

Energy Efficient - Reflective surface helps reduce heat absorption, keeping interiors cooler.

Long Lifespan - Typically lasts 30-50 years with minimal maintenance.

Stone Coated Steel Roofing Sheet Specifications

CategoryDetails

| Material | Al-Zinc Steel Sheet (Galvalume) with Natural Stone Granules |

| Overall Size | 1340mm × 420mm / 1400mm × 420mm |

| Effective Coverage | 1270mm × 380mm / 1335mm × 380mm |

| Lifespan | 30-50 Years Warranty |

| Thickness | 0.4mm, 0.45mm, 0.5mm |

| Weight | 2.6 - 3.0 kg per piece |

| Raw Material Characteristics | Al-Zinc Steel Sheet: High corrosion resistance, heat resistance, and durability Stone Granules: UV-resistant, fade-resistant, soundproofing, and aesthetic appeal |

| Workmanship | Multi-layer coating process, high-temperature adhesion, uniform stone granule coverage for long-lasting durability |

| Surface Coating | Acrylic Resin Binder + Stone Coating + Protective Clear Acrylic Layer |

| Weather Resistance | UV Protection, Anti-Corrosion, Anti-Fading, Impact Resistance |

| Fire Resistance | Class A Fireproof Performance |

| Wind Resistance | Withstands Strong Winds and Storms |

| Installation | Lightweight and easy interlocking system, suitable for various roof structures |

| Applications | Residential Houses, Villas, Commercial Buildings, Schools, Industrial Warehouses |

| Available Colors | Charcoal, Red, Coffee Brown, Green, Blue, Customized Colors |

| Customization | Various profiles, textures, and colors available to meet project needs |

This table includes additional technical parameters, material characteristics, and performance benefits. Let me know if you need further modifications!

Stone Coated Metal Roof Tile - Product Overview

1. Woodshake ProfileDescription: Mimics the look of natural wood shingles while offering superior durability.

Parameters:

Size: 1340mm × 420mmEffective Coverage: 1270mm × 380mmThickness: 0.4mm / 0.45mm / 0.5mmWeight: 2.6 - 3.0 kg per piece

Advantages:

Classic wood aesthetic with enhanced durability

Fireproof and weather-resistant

Lightweight and easy to install 2. Milano ProfileDescription: A sleek, modern profile with soft curves, ideal for contemporary homes.

Parameters:

Size: 1340mm × 420mmEffective Coverage: 1270mm × 380mmThickness: 0.4mm / 0.45mm / 0.5mmWeight: 2.6 - 3.0 kg per piece

Advantages:

Elegant and smooth appearance

High wind resistance

UV and corrosion-resistant 3. Roman ProfileDescription: Inspired by traditional Roman-style roofing with distinct wave patterns.

Parameters:

Size: 1340mm × 420mmEffective Coverage: 1270mm × 380mmThickness: 0.4mm / 0.45mm / 0.5mmWeight: 2.6 - 3.0 kg per piece

Advantages:

Luxurious and timeless European style

Strong impact resistance

Long lifespan (30-50 years) 4. Big Roman ProfileDescription: A larger version of the Roman profile, providing an even bolder roofing design.

Parameters:

Size: 1400mm × 420mmEffective Coverage: 1335mm × 380mmThickness: 0.4mm / 0.45mm / 0.5mmWeight: 2.8 - 3.2 kg per piece

Advantages:

Ideal for large-scale residential and commercial projects

High-strength Al-Zinc steel for extra durability

Fade-resistant stone coating 5. Classic ProfileDescription: A multi-color profile offering a mix of shades for a unique and attractive look.

Parameters:

Size: 1340mm × 420mmEffective Coverage: 1270mm × 380mmThickness: 0.4mm / 0.45mm / 0.5mmWeight: 2.6 - 3.0 kg per piece

Advantages:

Aesthetic and customizable color combinations

Excellent thermal insulation

Suitable for various architectural styles 6. Tudor ProfileDescription: A clean and minimalist profile for a modern and sophisticated look.

Parameters:

Size: 1340mm × 420mmEffective Coverage: 1270mm × 380mmThickness: 0.4mm / 0.45mm / 0.5mmWeight: 2.6 - 3.0 kg per piece

Advantages:

Perfect for contemporary and minimalist designs

High fire resistance (Class A)

Strong load-bearing capacity General Advantages of Stone Coated Metal Roofing TilesDurability: Made from high-quality Al-Zinc steel, providing 30-50 years of lifespan

Weather Resistance: Withstands heavy rain, strong winds, hailstorms, and UV exposure

Fireproof: Class A fire resistance, ensuring safety from fire hazards

Lightweight: Lighter than traditional clay tiles, reducing structural load

Eco-Friendly: Recyclable materials with low environmental impact

Easy Installation: Interlocking design for quick and hassle-free installation

Color Options for Stone-Coated Roof TilesWhen purchasing stone-coated metal roofing tiles, selecting the right color is crucial for both aesthetic appeal and functional benefits. Here are the available color options:

Standard Color Options:Spanish Red - A classic and vibrant red, perfect for traditional and Mediterranean-style homes.Black Red - A deep reddish-black hue, providing a bold and modern appearance.Brick - A warm earthy tone that blends well with rustic and natural landscapes.Terracotta - A timeless clay-like shade, ideal for homes with a classic or European touch.Sunny Orange - A bright and energetic color for a lively and standout roofing look.Neutral & Earthy Tones:Coffee Brown - A rich, warm brown that complements wood and brick exteriors.Dark Brown - A deeper brown shade, offering a sophisticated and elegant look.Cool & Modern Shades:Sky Blue - A bright and refreshing blue for a unique and modern touch.Black - A sleek and bold color for contemporary and minimalist designs.Ocean Blue - A deep blue hue, adding a coastal or nautical feel to your roof.Natural Green Variants:Dark Green - A forest-inspired shade that blends seamlessly with natural surroundings.Forest Green - A slightly lighter green, ideal for eco-friendly and nature-oriented designs.Gray & Black Variants:Smoky Gray - A soft gray tone, providing a modern and industrial look.Ink Gray - A darker, near-black gray for a sleek and sophisticated appearance.Black & White - A stylish contrast that adds a unique touch to your roof.Choosing the Right ColorWhen selecting a color, consider:

Architectural Style - Traditional homes look great with terracotta or brick tones, while modern homes often suit black, gray, or blue.

Climate Considerations - Lighter shades reflect heat, while darker shades absorb it, affecting energy efficiency.

Surrounding Environment - Choose a shade that complements the natural surroundings and landscape.

Would you like assistance in selecting the best color for your specific project?

Project Show

Production Process Effective production management ensures high-quality stone-coated roof tiles with durability, efficiency, and cost-effectiveness. Implementing automation, quality control, and optimized logistics enhances competitiveness and customer satisfaction. 1. Raw Material Procurement & Quality ControlMaterials:

High-quality Al-Zinc (Galvalume) steel sheets for durabilityNatural stone granules with UV-resistant coatingAcrylic resin for bonding and surface protectionQuality Control Measures:

Ensure Al-Zinc steel meets 0.4mm - 0.5mm thickness standard

Stone granules should be colorfast and fade-resistant

Regular testing of adhesive strength and weather resistance

2. Advanced Production ProcessCutting & Shaping - Precision cutting of steel sheets into desired tile profiles (Woodshake, Milano, Roman, etc.)

Press Forming - Using high-pressure stamping machines to create consistent tile shapes

Base Coating - Applying a protective layer to enhance adhesion and corrosion resistance

Stone Coating Process - Uniform application of natural stone granules to ensure aesthetic appeal and durability

Curing & Drying - High-temperature curing to improve adhesion strength and weather resistance

Surface Protection - Final application of an acrylic resin coating for UV and moisture protection

3. Quality Inspection & TestingTests Performed:

Coating Adhesion Test - Ensures strong bonding between steel and stone granulesWeather Resistance Test - Simulates extreme conditions (UV, rain, wind)Impact Resistance Test - Measures durability against hail and debris impactFireproofing Test - Compliance with Class A fire resistance standardsInspection at each stage of production to prevent defects

4. Production Efficiency & Process OptimizationLean Manufacturing Techniques

Reduce material wastageImprove workflow efficiencyMinimize production downtimeAutomation & Technology Use

CNC machines for precise cuttingRobotic coating systems for uniform stone granule applicationAI-based quality inspection for defect detection 5. Packaging & Logistics ManagementProtective Packaging

Use foam separators and wooden pallets to prevent damageShrink wrapping to protect against moisture and dustInventory Management

Maintain adequate stock levels to avoid production delaysImplement real-time tracking of raw materials and finished productsEfficient Delivery System

Optimize loading capacity to reduce shipping costsPartner with reliable logistics providers for safe and on-time delivery 6. Compliance & Environmental ConsiderationsCertifications & Standards

Meet ISO 9001 Quality Management SystemCompliance with environmental and fire safety regulationsEco-Friendly Production

Use non-toxic adhesives and coatingsImplement waste recycling programs for scrap materials Packaging & Shipping

Proper packaging and delivery of stone-coated metal roof tiles are crucial to ensure they arrive at their destination in perfect condition, preventing damage during transportation and handling. Here's a detailed guide:

1. Packing Method for Stone-Coated Roof TilesA. Layered StackingSeparate each tile with a protective film or foam sheet to prevent scratches.Stack tiles in uniform bundles (usually 500-600 pieces per crate) to avoid shifting during transit.B. Wooden Pallet or Metal Frame CratesUse durable wooden pallets or metal crates to provide structural support.Secure tiles with plastic straps or steel bands to prevent movement.C. Protective WrappingPlastic shrink wrap around the entire stack to protect from dust, moisture, and weather conditions.Optional: Waterproof covers for added protection during long-distance shipping.D. Accessories PackingRidge caps, barge covers, and flashing should be packed separately in protective packaging.Small accessories like nails and fasteners should be boxed securely to prevent loss. 2. Loading and Transportation GuidelinesA. Optimizing Container SpaceTypically, a 20ft container holds 5000-7000 pieces of roof tiles.Accessories and small items are loaded in side compartments or top sections to maximize space.B. Securing the LoadUse wooden braces and padding to prevent movement inside the container.Secure pallets with ratchet straps for added stability.C. Transportation ModesSea Freight: Most economical for bulk orders. Tiles should be moisture-protected.Truck Delivery: Ideal for domestic transportation; ensure road stability.Air Freight: For urgent orders, though costly. Packaging must be reinforced to withstand handling. 3. Unloading and Handling PrecautionsUse a forklift or crane to unload pallets safely.

Avoid dropping or dragging tiles to prevent damage.

Store in a dry, shaded area before installation to maintain quality.

Raw Materials

Premium Stone Chips for Forsetra® Roof TilesAll Forsetra® stone-coated roof tiles are coated with high-quality natural stone chips, ensuring superior durability, weather resistance, and aesthetic appeal. Our stone granules are volcanically formed and sourced exclusively from premium quarries in France and CG Rock, the most renowned Chinese-brand stone granule supplier.

Unlike low-quality alternatives, we never use synthetic or low-grade stone chips from unverified factories. These inferior materials may be cheaper but suffer from poor adhesion, color fading, and reduced weather resistance, compromising roof longevity.

Key Parameters of Forsetra® Stone Chips

ParameterSpecification

| Source | Volcanic-origin natural stone granules |

| Primary Suppliers | French quarries & CG Rock (China) |

| Granule Size | 1.0mm - 2.5mm (optimized for even coating) |

| Coating Material | Ceramic-coated for UV and weather resistance |

| Color Stability | Fade-resistant, tested under extreme conditions |

| Impact Resistance | Withstands hail impact and mechanical stress |

| Water Resistance | 100% waterproof, prevents moisture penetration |

| Environmental Impact | Non-toxic, eco-friendly, and recyclable |

Advantages of High-Quality Stone ChipsEnhanced UV & Weather Resistance - Prevents discoloration and extends roof lifespan

Superior Adhesion - Strong bonding with acrylic resin, reducing granule loss over time

Impact Resistance - Protects against hail, debris, and extreme weather conditions

Aesthetic Versatility - Available in various colors and textures for different architectural styles

Eco-Friendly & Safe - Non-toxic, sustainable materials with no heavy metals

GALVALUME STEEL - High-Performance Roofing MaterialGalvalume steel is a premium roofing and construction material known for its exceptional corrosion resistance, durability, and thermal efficiency. It is coated with a specialized Al-Zn-Si alloy, offering superior protection against environmental factors.

1. Chemical Composition & Coating DetailsGalvalume steel is coated with a precise blend of aluminum, zinc, and silicon, enhancing its performance in extreme weather conditions:

ElementWeight Ratio (%)Surface Volume Ratio (%)Function

| Aluminum (Al) | 55% | 80% | Enhances corrosion resistance, improves heat reflectivity |

| Zinc (Zn) | 43.4% | 19% | Provides sacrificial protection to prevent rusting |

| Silicon (Si) | 1.6% | 1% | Increases coating adhesion and improves durability |

2. Technical ParametersGalvalume steel sheets are manufactured with precise control over thickness, coating weight, and mechanical properties to meet industry standards.

ParameterSpecification

| Coating Thickness | AZ50 - AZ150 (50g/m² - 150g/m²) |

| Steel Thickness | 0.25mm - 1.2mm |

| Tensile Strength | 300 - 550 MPa |

| Yield Strength | ≥ 245 MPa |

| Elongation | 15% - 30% (depends on grade) |

| Heat Reflectivity | Up to 75% |

| Service Life | 25 - 50 years (depending on environment) |

3. Key Features & AdvantagesSuperior Corrosion Resistance: Outperforms galvanized steel with up to 3X longer lifespan in coastal and industrial environments.

High Heat Reflectivity: Reduces heat absorption, improving energy efficiency in buildings.

Exceptional Strength & Flexibility: Withstands extreme weather conditions, including strong winds and heavy snow.

Self-Healing Effect: Zinc acts as a sacrificial layer to protect exposed steel edges from rust.

Aesthetic & Paint-Friendly: Offers a smooth, uniform surface that enhances paint adhesion and longevity.

Eco-Friendly & Recyclable: 100% recyclable, reducing environmental impact.

4. Applications & UsesGalvalume steel is widely used in various roofing, cladding, and structural applications due to its durability and cost-effectiveness.

Roofing & CladdingStone-coated metal roofing tiles

Standing seam & corrugated roofing sheets

Residential, commercial, and industrial roofs

Wall panels and facades

Structural & Industrial ApplicationsPre-engineered steel buildings (PEB)

Agricultural storage facilities & silos

Highway guardrails & sound barriers

Solar panel mounting structures

Automotive & Home AppliancesTruck and trailer body panels

Air conditioning units & HVAC systems

Electrical enclosures and cabinets

5. Why Choose Galvalume Over Galvanized Steel?

FeatureGalvalume SteelGalvanized Steel

| Corrosion Resistance | 2-4X longer lifespan | Lower resistance to rust |

| Heat Reflectivity | High (75%) | Lower (55%) |

| Paintability | Excellent adhesion | Prone to peeling over time |

| Coastal Suitability | Better resistance to salt spray | Prone to rust in humid conditions |

Related Products

1. Key Roofing Accessories & Their FunctionsSidewall Flashing: Protects the intersection between the roof and a vertical wall, preventing water penetration.Flat Sheet: Used for custom cutting and fabrication of roofing accessories.Nails: Specially coated nails for securely fastening stone-coated metal tiles to the roof structure.Box Barge Cover: Covers and seals the roof's barge area, preventing wind-driven rain from entering.Valley Gutter: Directs rainwater away from the valleys of the roof to the drainage system.Eave Flashing: Installed at the roof's eave to prevent water infiltration and reinforce roof edges.Barrel Ridge: Enhances the appearance and provides a weatherproof seal along the ridge of the roof.Angle Ridge: Seals and protects ridge intersections while adding structural integrity.End Cap Barrel Seal: Closes off open barrel ridge ends, ensuring a watertight seal. 2. Advantages of Stone-Coated Roofing AccessoriesSuperior Waterproofing: Effectively prevents leaks and protects against extreme weather conditions.

Long-Lasting Durability: Made from high-quality Galvalume steel with a stone-coated finish, ensuring a 50+ year lifespan.

Aesthetic Appeal: Matches seamlessly with stone-coated metal tiles, enhancing the roof's elegance.

Wind & Impact Resistance: Strong enough to withstand hurricanes, hail, and heavy snowfall.

Easy Installation & Maintenance: Lightweight and designed for fast, secure installation.

3. ApplicationsResidential Homes (Villas, Townhouses, Bungalows)

Commercial & Industrial Buildings

Resorts, Schools, and Government Structures

High-Wind & Snow-Prone Areas

Goods Features Stone-coated metal roofing is an innovative, durable, and visually appealing roofing solution that offers superior protection against fire, weather, and noise, all while maintaining a lightweight and easy-to-install design. It is the perfect choice for modern and traditional buildings alike. 1. Fireproof Made from non-combustible Galvalume steel with a stone-coated surface, these tiles provide excellent fire resistance, making them a safe choice for fire-prone areas.

2. Lightweight Compared to traditional concrete or clay tiles, stone-coated metal roofing is significantly lighter (around 6-7 kg/m²). This reduces the structural load on buildings, making it easier and more cost-effective to install.

3. Dampens Roof Noises The stone-coated surface effectively absorbs sound, reducing rainfall noise and other external sounds, making the interior quieter.

4. Suitable for Pitched Roofs (≥ 15°) Ideal for roofs with a slope of 15 degrees or more, ensuring efficient water drainage and preventing leaks.

5. Easy Transportation The lightweight design and stackable structure make shipping and handling more efficient, reducing transportation costs.

6. Roof Ventilation is Workable Designed to allow proper ventilation, preventing moisture buildup and extending the lifespan of the roof structure.

7. Bad Weather Proof Resistant to extreme weather conditions, including strong winds, heavy rain, snow, and hail, making it perfect for all climates.

8. Classical Appearance The natural stone-coated texture mimics traditional roofing materials like clay, wood, and asphalt shingles, offering a beautiful and timeless aesthetic.

9. 50 Years Warranty Built with high-quality Galvalume steel and durable stone granules, this roofing solution offers a long lifespan of 50+ years, ensuring excellent return on investment.

10. Snow Proof The non-porous stone-coated surface prevents snow accumulation, reducing the risk of structural damage and ensuring smooth snow shedding.

Quality control

A comprehensive quality control system ensures that stone-coated roof tiles meet the highest standards in durability, weather resistance, and aesthetic appeal. By implementing strict raw material checks, process monitoring, final testing, and packaging control, manufacturers can maintain consistent product quality and customer satisfaction. 1. Raw Material InspectionObjective: Ensure all materials meet production standards before processing.

Al-Zinc Steel (Galvalume) Sheet:

Thickness verification (0.4mm - 0.5mm) using micrometers

Coating composition test (55% aluminum, 43.4% zinc, 1.6% silicon)

Tensile strength and flexibility testing

Natural Stone Granules:

Color consistency check (to prevent fading issues)

Granule size analysis for uniform texture

UV resistance test for long-term durability

Acrylic Resin Binder:

Adhesion strength test (ensures strong bonding of granules)

Weather resistance testing

2. Production Process Quality ControlObjective: Monitor each stage to prevent defects and maintain consistency.

Cutting & Shaping StageVerify tile dimensions and edges to match design specifications

Ensure no burrs or sharp edges

Press Forming StageInspect shape consistency and correct press pressure settings

Check for uniform curvature and tile alignment

Base Coating & Adhesive ApplicationEnsure even application of protective base coating

Check adhesive bonding strength before granule application

Stone Granule CoatingVerify even stone granule distribution (avoiding clumps or gaps)

Confirm proper granule adhesion strength through shear tests

Curing & Drying ProcessMonitor temperature and drying time to avoid defects

Ensure complete bonding of granules to prevent peeling

Surface Protection (Acrylic Resin Coating)Check for uniform acrylic resin application

Verify UV resistance to prevent discoloration

3. Final Quality Inspection & TestingObjective: Ensure the finished product meets industry standards and customer expectations.

Coating Adhesion Test:

Check the bond between stone granules and steel sheet

Perform scratch and peeling tests

Weather Resistance Tests:

Salt Spray Test (to simulate corrosion resistance)

Freeze-Thaw Cycle Test (to ensure tiles withstand extreme temperature changes)

UV Aging Test (to assess long-term color stability)

Impact Resistance Test:

Drop-weight test to simulate hail impact

Check for cracking, chipping, or detachment of granules

Fire Resistance Test:

Compliance with Class A fire rating standards

Flame exposure test to confirm non-flammability

Waterproofing Test:

Ensure zero water penetration under heavy rain simulation

Weight & Size Verification:

Random sampling to confirm tile thickness, width, and length accuracy

Ensure each tile meets the expected weight range (2.6kg - 3.0kg per piece)

4. Packaging & Storage Quality ControlObjective: Prevent damage during storage and transportation.

Use foam separators between tiles to prevent scratches

Stack tiles on wooden pallets for stability

Ensure shrink wrapping for protection against dust and moisture

Conduct random sampling of packaged goods before shipment

5. Compliance & Certification ControlObjective: Meet international quality and safety standards.

ISO 9001 - Quality Management System

CE Certification (for European market)

ASTM & SGS Testing Reports

Environmental compliance (non-toxic materials, recyclable components)

Why Choose Hangzhou Forsetra?With 15 years of industry expertise, state-of-the-art production equipment, and advanced technology, Hangzhou Forsetra Roof Tile Co., Ltd. upholds a commitment to quality, integrity, and innovation. Established in 2018, we specialize in manufacturing stone-coated metal roof tiles and asphalt shingles, delivering durable and high-performance roofing solutions.

1) Premium Quality & Long-Term AssuranceOur products come with a 50-year warranty, ensuring long-lasting durability and giving you confidence in your investment.

2) Competitive & Cost-Effective PricingBy eliminating middlemen, we offer factory-direct prices while maintaining superior product quality.

3) Comprehensive Customer SupportWe provide our importers with customer insights, installation guidance, and marketing support, helping them boost sales and expand their business.

4) Fast & Reliable DeliveryWith four advanced production lines, we guarantee a delivery timeframe of 10-15 days, ensuring quick order fulfillment.

5) Complete Roofing SolutionsIn addition to our roofing tiles, we offer a full range of related materials, including:

Sealants & Asphalt GlueColored Sand & NailsSteel Trusses & Roof GuttersWaterproof MembranesThis enables optimized container loading, reducing shipping costs and maximizing efficiency.

At Hangzhou Forsetra, we are committed to delivering exceptional roofing solutions that combine quality, affordability, and expert service. Partner with us for innovative and reliable roofing materials!

>>

2025 New Year Hot Seller Discount Boat Manufacture Fiberglass Aluminium 8.2m Pontoon Boat with 150HP Motor Yacht Fishing Boat

>>

Certified USA Efficient Window Manufacturer Tilt Turn Window 19A/27A Blinds Inside Aluminum Frame Window Hotel Used

>>

Aerated Concrete Prodution Line, AAC Production Line Supplier

>>

Clear Hard Minor Radius Curved Tempered Glass for Household Furnace

>>

small noodle making machine noodle forming machine

>>

300g x 0.01g Digital Scale WH-I2000 0.01g Superior Mini Digital Platform Scale

>>

Baoyu CNC Precision Machine Tool B20 CNC Swiss Type Lathe Machine

>>

HDPE Net Fishing Net Nylon Net

>>

No Pain No Radiation Alleviate Fatigue For Health Medical Device

>>

SDMC20-S Digital single-phase AC asynchronous motor controller

>>

Handheld Series Lcc-Continuous Laser Cleaning Machine (Rust remover)

>>

Electronic Set Top Box Thermal Solution Aluminum Heat Sink CNC Milling Drilling Machining Aluminum Alloy Heat Sinks

>>

Custom Inflatable Octopus Wearing Headphone Dome Tent for Musical Festival Decoration

>>

Zlp800 Steel Platform/Metal Lifting Scaffold/Mobile Working Basket

>>

Module spare parts 560CMU05

>>

Galvanized Angle Steel Telecom Communication 4 Leg Angular Lattice Tower

>>

Grey Melange Fabric Office Chair Wood Office Working Chair Boss Chair

>>

Factory direct sales of degradable disposable cutlery and spoon

>>

Wholesale high quality Auto parts Regal Lacrosse Malibu XL 1.8 car oil filter housing For Chevrolet Buick 55581537

>>

Wholesale Good Quality High Heat Efficient Radiant Heat Poultry Heater Brooder for Chicks