|

US$30.00-300.00

|

1 Set

(MOQ)

|

Basic Info.

Automatic Grade

Automatic

Transmission Method

Machinery

Applicable Industries

Manufacturing Plant

Core Components

Drying Room

Application

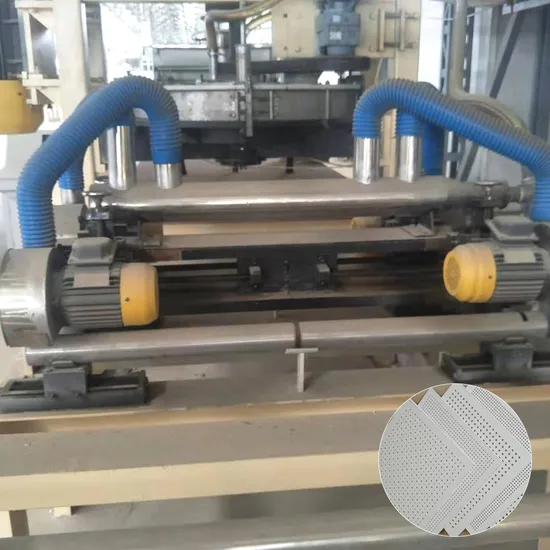

Construction Material Gypsum Board Production Line

Fuel

Coal; Diesel; Natural Gas; Heavy Oil

Material

Stainless Steel; Premium Carbon Steel

Drying Technology

Heat Transfer Oil; Hot Air

Automatic

Full Automatic; Semi Automatic; Low Automatic

Conrol System

PLC Centralized Control

Transport Package

Seafreight Package

Specification

based on production capacity

Packaging & Delivery

Package Size

100.00cm * 80.00cm * 40.00cm

Package Gross Weight

20.000kg

Product Description

Company Profile

Our company has many years of experience in producing gypsum board and gypsum powder production line, identified by the Commerce Department as Designated Equipment Manufacturer. According to our more than ten years experience and surveys from the customers., we always provide advanced technology content, high reliability ,lower operation and qualified gypsum board technology scheme. Product Description

| Machine advantage | Dosing system | 1)The dosing system has a high accuracy .

2)Starch mixing tank use stainless steel, with long service life and low corrosive.The foaming agent reserve tank is made of stainless steel.

3)Foaming system adopts domestic advanced technology-Dynamic and static foaming system, ensuring the finished board is lightweight, good bending strength andit can help to saving much cost. |

| Paper supply system | Adopting pneumatic tension bridle shaft to clamp paper rolls, improving production speed, reducing the labor intensity when manual clamping.

Reduce the waste of paper and the manual jobs and improve the joint neat standard. |

| Forming system | Adaption of our company newly developed core slurry receiving machine and discharging material technology avoids the inconsistency of manual operation, and ensures the quality of gypsum board, and reduces the manual jobs.

A complete set of molding system controlled by frequency conversion, adapting to the diversity of the product. |

| Cutting system | With the adoption of developed core servo cutting technology of our company, adjusting the required plate dimension by digital controller.

Maximally reducing cost by controlling the minimum edge horn size.

The whole cutting system is controlled by servo machine, applying to diversity of products. |

| Drying system | Full automatic control, without manual operation.Characteristics :(A) less manual work (B) improving drying efficiency of the drying machine (C) save energy consumption (D) improving the immanent quality of gypsum board and the first rate of all products.

Adopting steam recycling environmental protection and energy saving device developed independently by our company to save water consumption greatly. |

| Discharging board system | Parts and components manufactured elaborately is to ensure the reliability of the whole system.

Digital automatically adjust the saw cutting width.

Adopting servo motor control, ensuring the precision of the position plate movement, to adapt to the diversity of the product. |

Product Parameters

| Length(mm) | 2400,2440,2500,2700,3000 |

| Width(mm) | 1200,1220 |

| Discrepancy of the length and width(mm) | Length 0-6 Width 0-5 |

| Thickness(mm) | 8,9,9.5,12,12.5,12.7,15,18 |

| Discrepancy of the thickness(mm) | 0±0.5 0±0.6 |

| Discrepancy of the diagonal(mm) | ≤5 |

| Crippling load of the board(N) | 9.5: portrait>=360 landscape orientation >=140

12: portrait ≥500 landscape orientation ≥180 |

| Rate of water content | <2% |

Project show

Service:

1) Pre-sales: Full cooperation with pre-preparation work

2) In-sales: On-time reporting of production progress

3) After-Sales: Lifetime & 24h technical support

FAQ:

Q: How long is the warranty of your equipment?

A: 1year

Q: Do you supply spare parts?

A: Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year.

Q: Will you provide training?

A: The training is free of charge , and our engineer will be on duty to train your worker.

Q: How will you provide installation&commissioning

A: Will provide 2~8 persons(adjustable according to the degree of automatic )for installation. Engineers team will go with your project.

Q:How long time for the installation and commissioning

A: depend on configuration normally only need 15-25days. Including workers training.

>>

3ton Single Girder Bridge Crane

>>

High Quality Automacit Alarm Toroidal Core Transformer Winder with CE Certificate

>>

Most Popular Compact Excavator Free Shipping Mini Excavator Chinese Crawler Digger Earth Moving Machine Mini Excavator Small Digger

>>

China Manufacturer Supply Building Material Anti-Static Access Floor HPL Panel for Computer Room, Data Center

>>

Non-Slip Glazed Ceramic Indoorrustic Tile Bathroom Ideas for Wall Decoration

>>

Truck Loading Motorized Expanded Flexible Roller Conveyor Manufacturer Joinsun China UL CE

>>

Chengming Crafts Factory Wholesale Industrial Bookcases Bookshelf Home Office Furniture Corner Wooden Book Shelf Rack for Living Room

>>

Gaide Top Supplier Breshless Cordless Chainsaw with Two Battery

>>

High Quality Carbon Steel Chain Pipe Wrench

>>

Automatic Pick and Place Machine Carton Packing Machine Bottle Packer

>>

Pressure Hollow Block Making Machine, Brick Machinery Automatic Hydraulic Forming Machine

>>

Glass Fiber Rod with High Strength and Toughness D=10mm

>>

65W Type-C Pd Power Adapter ETL FCC CE Ukca SAA

>>

Durable Tungsten Carbide Chute Liner for Heavy-Duty Applications

>>

LINGKE Good after-service plastic sheet welder 20kHz 2000W plastic pipe welder

>>

Mesh Zipper Bag A4 Clear Frosted EVA Ticket Storage Bag

>>

High quality PTSA 98%1,3,6,8-pyrenetetrasulfonic acid TETRASODIUM SALT CAS No. 59572-10-0/ fluorescent tracer

>>

1.2 M Transparent Body Zorbing for Kids

>>

USB to Dual PS2 Mouse Keyboard Converter Cable

>>

OEM Quality Guaranteed Customize Size 65mn High Carbon Saw-Blade Hard Tooth Quenched Teeth Bandsaw Blade Used for Wood Meat Cutting