|

US$17.00-45.00

|

500 Square Meters

(MOQ)

|

Basic Info.

Model NO.

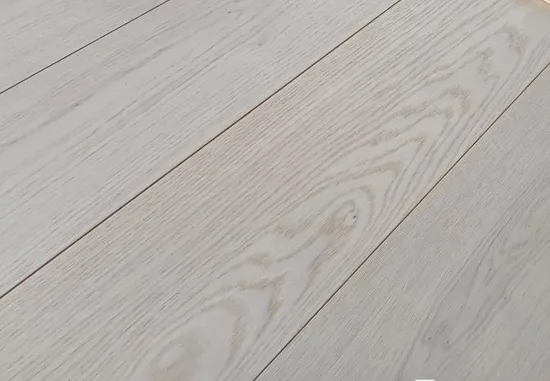

white Oiled ABgrade

Function

Waterproof, Soundproof

Processing Technic

Little Brushed

Certification

CE, FSC, ISO9001

Usage

Household, Commercial

Transport Package

Export Standard Carton & Ippc Pallets

Specification

1900*190*14/2mm Prime grade

Trademark

SUNHOUSE BAMBOO OEM

Production Capacity

200000m2/Month

Packaging & Delivery

Package Size

192.00cm * 14.00cm * 15.00cm

Package Gross Weight

25.000kg

Product Description

product information: Product Show

| Size: |

| Top Layer | 2/3/4/5/6mm |

Total Thickness

(timber layer+plywood base) | 10/12/14/15/18/20/21mm |

| Width | 80/90/100/120/125/150/180/190/220/240/260/300mm |

| Length | 300/350/400/450/510/600/750/900/1200-2200mm |

| Technical Specification |

| Grade | AB/ABC/ABCD/CD |

| Varnishing | 5-9 layers coating of Treffert Aluminum Oxide finish |

| Base Core | Poplar&Eucalyptus&Birch |

| Glue | Dynea Glue |

| Moisture | 6-10% |

| Joints | 4 sides T&G, with mirco bevel,or Click System |

| Surface Treatment | Smooth/Brushed/Smoked/Saw cut/Handscraft/Distressed |

| Coating | UV Lacquered,UV Oiled,Invisible Lacquered,Invisible Oiled, Unfinished |

| Gloss | As Customer request |

| Packing | Export Standard Carton & IPPC Pallets |

| Payment Terms | T/T |

| Capacity | 200,000m2/month |

Engineered wood flooring is made up of multiple layers borne pressure in production up to 14kg/cm' which is more than many other manufacturers, which gives the flooring great load-bearing capacity and ,impact resistance. The formaldehyde emission of core board is less than 0.3 mg/, similar to water, reaching Japan F4 star standard (super E0 level. Moreover, engineered wood flooring is far less affected by temperature, and the overall .

thickness of 14/15 mm make the heat transfer effectively. thickness of 14/15 mm make the heat transfer effectively.

https://sunhousefloor.en.made-in-china.com/

>>

Garlic and onion PP woven weed control mat,plastic ground cover black weed kill fabric,100gsm anti grass gardening mat

>>

Custom decorative perforated metal sheet facade cladding

>>

Taijia ferromagnetic objects finder Concrete scanner Rebar Steel Locator

>>

Wholesale LED Moving Wedding Party Flameless Romantic Electronic Flicker Candle Set with Remote Control

>>

Grain Bean Seed Drum Type Precleaner Machine

>>

Cleaning Brush with Plastic Handle and Replaceable Microfiber Head

>>

5L bottle linear type water filling machine pure bottled water filling machine

>>

Multi-Functional Gas Cooker Stove with Integrated Oven for Chefs

>>

2024 4D Massage Chair Office Chair Furniture Massager Health-Medicine Beauty-Equipment

>>

Benory RGBW 2700K 45degree Smart Ground Light DC24V Loxone PWM Dimmable Smart Home Using

>>

Cheap Polyester Fabric for Sublimation Printing

>>

2025 Brand-New Mobile Hydraulic Concrete Placing Boom From China Manufacturer

>>

reinforcement epoxy steel-bonding adhesive, carbon fabric adhesive, crack repair adhesive, manufacturer

>>

S25 Series Double Arm Continuous Sand Mixer High Speed Mixing for Resin Sand and Water Glass Sand

>>

Automatic manufacturing deep-fried dough sticks machine and breadstick machine

>>

Elastic Fashion Wash Color Jeans Female Wholesale Processing Custom

>>

20" Commercial Electric Deck Conveyor Pizza Oven Industrial Baking Equipment Chain Pizza Oven

>>

Outdoor folding screen door garage door large openning space & modern designed color

>>

Modern Hurricane Impact Windows Building windows aluminium Double Glass Aluminum Sliding Windows

>>

High Quality Car Replace Engine Model 2.0t Bpj for Audi C6