Basic Info.

Type

Screw Fastening Robot

Power Supply Voltage

220V or 110V

Automation

Fully Automatic

Power Source

Electricity and Pneumatic

Drive Mode

Closed-Loop Motor+Synchronous Belt

Control Mode

Microontroller +Touch Panel

Screw Feeding

Magnetic Type

Programming

Traction Teaching Programming

Position Accuracy

+/-0.02mm

Alarm System

Stripped Thread Alarm

Air Pressure

0.4 - 0.8 MPa

Transport Package

Wooden Box Package

Specification

900mmX630mmX1295mm (with Signal Tower)

Production Capacity

500 Pieces/Year

Product Description

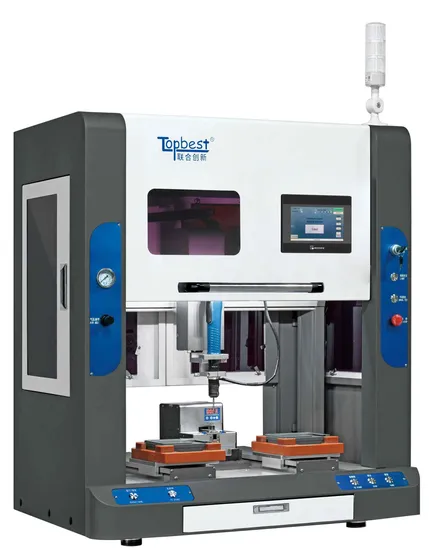

TBS-SM-6331C

Desktop Magnetic Type Single Head Dual Rail Automatic Screw Fastening Machine (Microcontroller Based)

Robotic screw driving machine is designed for screw fastening with high precision automatically.

Parameter

| Model | TBS-SM-6331C |

| Dimension | 900mmX630mmX1025mm

900mmX630mmX1295mm (with Signal Tower) |

| Max. product size | 200*280mm |

| Driving mode | Closed-loop Motor+Synchronous Belt |

| Control mode | Microcontroller +Touch Panel |

| Moving range | X Axis | X=580mm |

| Y1/Y2 Axis | Y1=280mm,Y2=280mm |

| Z Axis | Z=100mm |

| Max. speed | X, Y1/Y2 Axis | 600mm/sec |

| Z Axis | 400mm/sec |

| Repeated accuracy | X, Y1/Y2 Axis | ±0.02mm |

| Z Axis | ±0.02mm |

| Memory | 1000 Files |

| Screwdriver | SD/KILEWS/HIOS |

| Screw feeding | Magnetic |

| Programming | Traction Teaching Programming |

| Max load | 15KG |

| Alarm system | Stripped Thread Alarm |

| Net weight | 146KG |

| Input voltage | 220V AC/50Hz(110V AC/60Hz) |

| Air pressure | 0.4~0.8Mpa |

| Work environment | 0~40ºC, Humidity 20%~95% |

Advantage

1. Traction teaching programming

2. Deep-hole screw fastening

3. Servo screwdriver with torque tracibility (Option)

4. Rich experience on screw fastening application

FQA

1. Why is Robotic Screw driving machine?

-- To give better in term of quality such as same read out trace torque for each point of production.

-- Higher efficiency by reducing manpower at least one to three person.

2 What are the feeding types for the Robotic Screw Driving System?

-- We using the vibrator to sort the screw depending on screw type and size.

-- Firstly we using the pick and place of the screw presenter.

-- Another way is we using air blowing to feed directly to the screwdriver.

3. How to apply the screw to the product?

-- Mainly, we have 2 ways to screw the product which is magnetic for ferrous screw and vacuum for all material including ferrous, copper, stainless steel screw.

4. What kind of screws are fit for the air blowing type machine?

-- Screw models M1.4~ M4 are fit for air blowing feeding of screw driving machine.

-- Screw length must less than 16mm. If more than, the feeder needs to be customized.

-- The screw's length must be over 1.2 times of diameter for air blowing feeding type to prevent the screw from turn over inside the feeder's tube.

5. What kind of screws are fit for the screw presenter type machine?

-- Screw models M0.8 ~ M4 are fit for Magnetic, vacuum feeding of screw driving machine.

-- Machine screws, self-tapping screws, etc.

6. When does the machine have multiple electric screwdrivers?

-- For high efficiency, we offer dual screwdriver for simultaneously fastening for the product in array position.

7. What does an electric screwdriver the machine use?

-- Currently, we are using the electric screwdriver from Kilews, Sudong, DEPRAG, DESOUTTER, MOUNTZTORQUE, HIOS, and Atlas.

8. What is the range of the tapped hole's depth on the products?

-- The range is about 20mm, depending on customer product and must be magnetic screw type.

9. What is the common problem during the fastening process?

-- There are five common problems could occur throughout the process such as misalignment entry, broken screw, damaged thread, missing part and floating screw.

10. What are the differences between SC-2 and GW-4 ?

-- GW using gravity to transfer the screw to the nozzle and push to release the screw. The screwdriver nozzle contacted with the product surface and it is likely to slightly damage the surface.

-- SC-2 using air blowing to transfer the screw to the nozzle and push button to release the screw.

11. How is dual rail working?

-- Our machine has a dual rails system to allow loading on the second rail simultaneously while the first rail is on the fastening process.

12. What is the purpose of one rail system?

-- One rail system occupy small workspace or bigger product.

13. Does the machine come with a warranty?

-- The machine comes with one year warranty excluding consumable parts.

14. How about after-sale service?

-- We provide remote video and 24hours telephone or you may visit our company. On-site service will be charged accordingly.

15. What is the size of the working base?

-- Working base size as stated for each machine. Fixture size should be in consideration. However, the size of products can be customized according to customers.

16. Does the enclosure include?

-- You may select a model with or without an enclosure.

17. What are the safety features of the machine?

-- The emergency button is accessible for all machines. The safety door is optional.

18. Is the screw driving system compatible with other robots?

-- Our screw driving system is compatible with the SCARA robot, 6 axles robot.

19. Can I be your distributor?

-- Yes, we are open to any company that would like to become our distributor except in certain areas we already have our own agent.

20. Do you provide a fixture for the machine?

-- Yes, we also can design the fixtures based on customer products. For example, a rolling fixture for multiple surfaces fastening.

21. What is the delivery term?

-- EXW, FOB, DAP, FCA.

-- Lead time is 20 business days.

>>

High Efficiency Single Phase Two-Value Capacitor Asynchronous Motor with Cast-Iron Housing

>>

Modern Marble & Metal Table Lamp with Fabric Shade Hotel Lamp

>>

carbon padel racket P07 plush shape factory wholesale

>>

Professional LCL/FCL Truck Shipping Freight Forwarder From China to Europe Germany UK France

>>

42.6mm White Golf Balls Golf Putting Practice Ball Standard Blank Customizable Logo Golf Accessories

>>

Welding Machine for Sale, Automatic Brazing Machine

>>

CNC High Speed Plate Drilling Punching Marking Machine FINCM Tower Fabrication Steel Plate High-Speed CNC Hydraulic Punching Drilling Machine

>>

Australia AS2047 Thermal Break Aluminium Glass Windows Double Glazed Aluminum Casement Window

>>

Air conditioner radiator copper separator machine scrap copper wire crusher and separator machine

>>

Reliable Dtf Transfer Film Perfect for Direct Printing on Cotton and Polyester

>>

Miiiw Dual Mode Keyboard 104 Keys 2.4GHz Multi System Compatible for xiaomi gaming Office Wireless Keyboard

>>

Mountain Bicycle Brake Carbon Fiber 24 Speed Road Bike

>>

modern aluminium glass grill front door designs french aluminum swing double doors

>>

JOHNCOO 100g-200g Luminous Fast Jig Hard Lure Metal Jig Lures Fishing Tackle Bait Fast Sinking jigging Lure

>>

Price of aluminum sliding window rain protection in window and doors

>>

Taijia 0.01mm accuracy digital concrete crack width gauge crack detector test gauge with monitoring function

>>

Industrial Slaughter Poultry Waste Batch Cooker with ASME Certiticate

>>

Tonva Plastic Toy Ocean Sea Ball Making Extrusion Blow Molding Machine Price

>>

Plastic Injection Machine Ma5300 Plastic Frame Fruit Frame Injection Molding Machine

>>

Farm Use Cow Dung Manure Dewatering Machine China