|

US$43,500.00-70,000.00

|

1 Set

(MOQ)

|

Basic Info.

Making Method of Parison

Stretch Blow

Computerized

Computerized

Suitable Preform Material

Pet Preforms

Suitable Bottle Size

100ml-2000ml

Max. Bottle Neck Diameter

28-38mm

Max. Bottle Diameter

100mm

Dimension

6500*1500*1900mm

Name

Full Automatic Pet Bottle Blow Molding Machine

Transport Package

Wooden Case

Specification

Automatic machine with 6 cavities

Production Capacity

6000 PCS/Hour for 500ml

Product Description

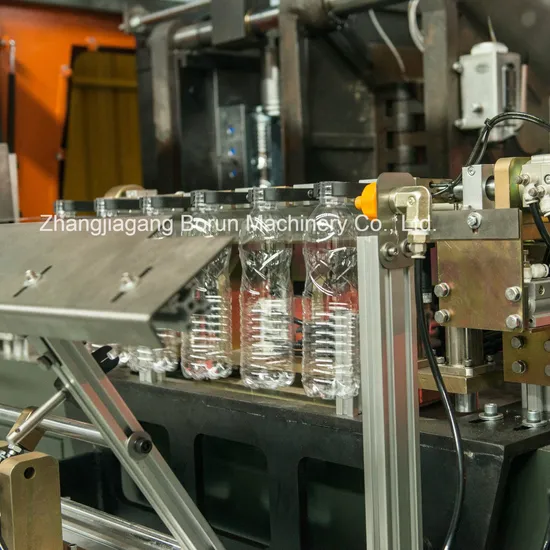

Full Automatic PET Bottle Blow Molding Machine With Six Cavities (BM-A6)

BM-A6 Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Equipment List:

| No. | NAME | MODEL | POWER | QUANTITY |

| 1 | Blow Molding Machine | BM-A6 | 56KW | 1set |

| 2 | HP Air Compressor | 6.0m3/min/30Kg | 66KW | 1set |

| 3 | LP Air Compressor | 1.6 m3 /min/10Kg | 15KW | 1set |

| 4 | Cold dryer(HP) | 6.0 m3/min/30Kg | 2KW | 1set |

| 5 | Cold dryer(LP) | 2.0 m3/min/10Kg | 0.45KW | 1set |

| 6 | Air Tank | 1m3/min/30Kg | / | 1set |

| 7 | Mold Chiller | 5HP | 4.4KW | 1set |

| 8 | High-pressure oil pipe | | | 15m |

| 9 | Bottle mold | 0.2-2L | 6cavities | / | 1set |

| 10 | Spare parts | | | 1set |

| 11 | Installation tools | | | 1set |

Features of main body:

1). Stable performance with advanced PLC.

2). Automatic preform conveyer to save human cost.

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5). High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Use SMC air cylinder to avoid contamination and noise.

7). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

8). Strong clamping force with high pressure and double crank links to lock the mould.

9). Two ways of operating: automatic and manual.

10). Low cost,high efficiency,easy operation and maintenance etc, profited from the fully automatic technological process.

12). Ideal cooling system make the finished bottles without any flaws. Technical parameters:

| Item | BM-A6L |

| Bottle type specification | Cavity | 6 |

| Theory output | 5000-6000 |

| Max.volume | 2L |

| Bottle mouth maximum overall diameter | 28-38mm |

| Bottle biggest diameter | 100mm |

| Bottle maximum height | 330mm |

| Power specifications | Light tube quantity | 32pcs |

| Light tube power | 1.5KW |

| Maximum heating power | 48KW |

| All electric machine installation | 55KW |

| Actual consumption | 20KW |

| Blow bottle pressure | 25-35kg/c |

| Higher -pressure gas consumption | 4000Ltr/min |

| Forzen water specification | Work pressure | 5-6 kg/c |

| Temperature range | 10ºC |

| Consumption | 8000kcal/hr |

| Forzen water flow | 88L/min |

| Machine specification | Size of the machine | 6.5x1.5x1.9 |

| Weight of the machine | 4ton |

Main parts:

| Name | Brand | Original |

|

| Cylinder | SMC | Japan |

| valve | SMC | Japan |

| Photoelectric switch | XIN | CHINA |

| Touch screen | MCGS | CHINA |

| PLC | Mitsubishi | Japan |

| Transducer | SMC | Japan |

| servo motor | HUICHUANG | CHINA |

Free spare part list:

| NUMBER | NAME | QTY/SET |

| 1 | Lamp | 10 |

| 2 | Seal ring | 10 |

| 3 | Tool box | 1 |

| 4 | stop button | 1 |

| 5 | starting switch | 1 |

| 6 | connector | 20 |

| 7 | Detection switch | 1 |

| 8 | Magnetic switch | 4 |

| 9 | Pressure regulating table | 1 |

| 10 | Temperature control module | 2 |

Fuctions of the accessory machines:

Air compressor is the air source for PET stretch blow molding machine, carrying out the process of compressing air from atmosphere to the required pressure.

Air dryer is to remove the moisture from the compressed air and lower temperature of the compressed air in the heat exchanger.

Air filter is to clear up the impurities out of the compressed air, like carbon hydrogen, tiny dust and solid particles.

Air tank is to keep the air stable ,to protect the Hp air compressor.

Water Chiller is to Cool the mould ,to prolong the life of the mould.

>>

High Efficiency Single Phase Two-Value Capacitor Asynchronous Motor with Cast-Iron Housing

>>

Modern Marble & Metal Table Lamp with Fabric Shade Hotel Lamp

>>

carbon padel racket P07 plush shape factory wholesale

>>

Professional LCL/FCL Truck Shipping Freight Forwarder From China to Europe Germany UK France

>>

42.6mm White Golf Balls Golf Putting Practice Ball Standard Blank Customizable Logo Golf Accessories

>>

Welding Machine for Sale, Automatic Brazing Machine

>>

CNC High Speed Plate Drilling Punching Marking Machine FINCM Tower Fabrication Steel Plate High-Speed CNC Hydraulic Punching Drilling Machine

>>

Australia AS2047 Thermal Break Aluminium Glass Windows Double Glazed Aluminum Casement Window

>>

Air conditioner radiator copper separator machine scrap copper wire crusher and separator machine

>>

Reliable Dtf Transfer Film Perfect for Direct Printing on Cotton and Polyester

>>

Carbon Crystal Doors: Multicolor Options, Flat Panel Simplicity Meets Sculpted Lines - Perfect for All Spaces, Factory Direct

>>

PP Jumbo Woven FIBC Container 1000kg Bulk Big Bag Super Sack Sling Baffle Bag Packaging Plastic One 1 Ton Bag Industry Sand Large Bulk Bag 2000kg Price Factory

>>

OEM 1327673 1619667 85000398 70320611 96975 High quality Heavy Duty Truck Cooling System Aluminum Intercooler For DAF 95 XF 1997-2002

>>

RF Labels Magnetic Alarm Security Barcode White Label 8.2MHz EAS RF Anti Theft Label Factory

>>

Gfrp Fiberglass Tank or Vessel Filament Winding Machine, Production Line, Mandrel or Mold for Diameter DN2200, 2400, 2500, 2600, 2800, 3000, 3200, 3500, 3600mm

>>

Training arm muscle chest expander arm strength gripper men's home fitness equipment sping pedal tensioner yoga rally

>>

Camera WiFi Connection Mobile Phone Printable

>>

Factory Make up Products 9 Glitter Color Palette Eyeshadow High Pigmented Eyeshadow Palette La Sombra De Ojos

>>

China Factory Wholesale Custom Metal Key Chain

>>

Brand New Auto Parts OEM 89467-33180 Oxygen Sensor for Toyota Camry