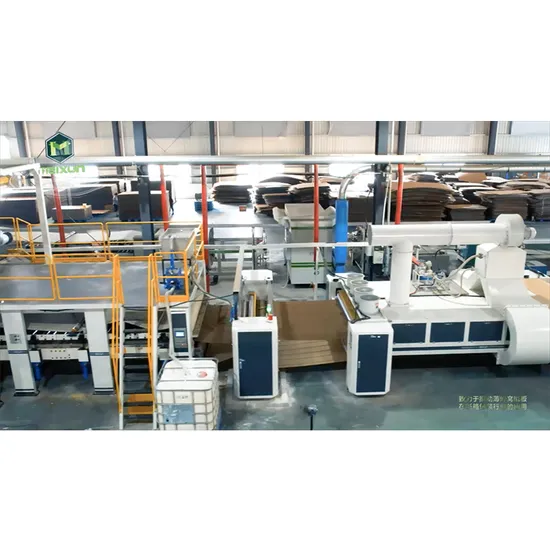

Product Description Main Technical Parameters of the Equipment: Discover the core specifications that make the Fast Honeycomb Cardboard Production Line a leader in the industry. Engineered with precision, this equipment offers unparalleled performance, integrating advanced technology to meet the rigorous demands of modern food packaging.

| | parameters | Specification |

| 1 | Facial paper (width x roll diameter) | 2 0 00mm×Φ1400mm |

| 2 | Effective width of finished paperboard | 1300mm- 2000mm |

| 3 | Paper weight | 140g/M²-- 4 20g/M² |

| 4 | Adhesive | starch glue |

| 5 | Finished paperboard thickness | 5-60mm |

| 6 | Finished paperboard length | 800mm -- 3500mm |

| 7 | Maximum production speed of honeycomb paperboard | 100m/min (sheet thickness 6mm, honeycomb side length 4.5 mm, core paper weight 80-100 grams, surface paper weight 170grams, paperboard length 2500mm) |

| 8 | heating method | steam heating |

| 9 | Equipment installed power | About 200KW _ |

| 10 | normal production power consumption | About 200 KW* 5 0%- 6 0% |

| 11 | Total weight of equipment | About 150 T (including dry unit) |

| 12 | Equipment Dimensions | 76000mm(length)×6000mm (width)×5100mm(height) |

| 13 | Direction of machine operation | based on customer's needs |

| | part name | project configuration | Remark |

| 1 | Finished paper core pulling unit | Up and down brush roller conveying | Stable conveying and even pulling |

| 2 | Paper Core Drying Unit | 6 M steam heating, hot air circulation | drying, shaping |

| 3 | Paper core conveying group | Synchronous paper core conveying group | Stable delivery |

| 4 | Facial paper shaftless paper holder | Hydraulic shaftless paper holder | Convenient |

| 5 | Arc Plate Preheating Group | Using arc hot plate | Steam heating , |

| 6 | Automatic paper splicer | Manufacturer standard | outsourcing |

| 7 | Lower core surface glue coating unit | Anilox roller gluing, metering roller independent control | The upper rubber roller is finely ground, and the amount of glue is uniform and controllable |

| 8 | paperboard composite drying group | with deep hole drilling steam ironing board

Composite with pressure roller and cotton conveyor belt | Less steam consumption, firm composite, controllable moisture content of paperboard |

| 9 | Tissue preheating 2 | Equipped with diameter Φ 1000 preheating cylinder | Steam heating , adjustable wrap angle |

| 10 | Upper core surface glue coating unit | Anilox roller gluing, independent control of metering roller, the whole gluing part can be raised and lowered | The upper rubber roller is finely ground, and the amount of glue is uniform and controllable |

| 1 1 | paperboard composite drying group | with deep hole drilling steam ironing board

Composite with pressure roller and cotton conveyor belt | Less steam consumption, firm composite, controllable moisture content of paperboard |

| 1 2 | paperboard cooling unit | Channel steel frame structure | |

| 1 3 | Servo slitting unit | 5 knives 8 lines | |

| 1 4 | Automatic spiral knife cross cutting machine | Spiral knife structure | |

| 1 5 | paperboard collection unit | Small longmen Collection | |

| 1 6 | other | Main electrical producing areas : Taiwan , Japan , South Korea , domestic | |