|

US$10.00-300.00

|

1 piece

(MOQ)

|

Basic Info.

Processing Type

Mechanical Process

Match Machine

Chemical Fiber Spinning Equipment

Processing Level

Precision Finishing

Processing Trade

Processing with Material Supplied

Certification

CE, ISO9001: 2000

After-sales Service

12months

Operating Pressure Inner Shell

10MPa

Operating Temperature

310 Centigrade

Filter Unit

Filter Candle

Filter Layer Material

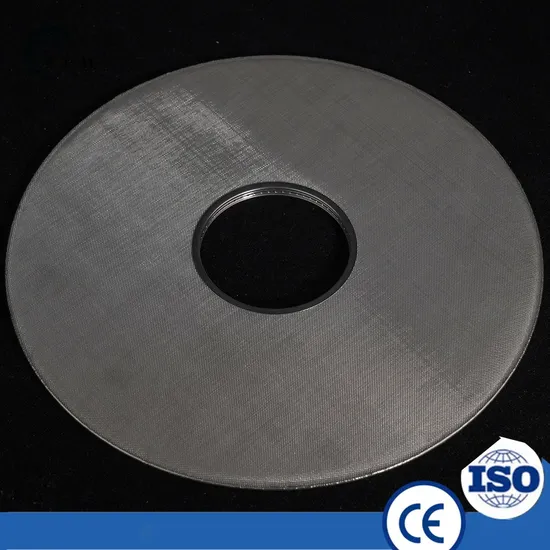

Stainless 304 or 316 Wire Mesh or Sintered Felt

Transport Package

Seaworthy Package

Specification

see technical parameters

Production Capacity

4500PCS/Year

Product Description

Product Description

Mode

| CPT filter elment | Product

| polymer or fluide |

| Filter rate | 3-100micron | Type | Pleated filter element |

| Filter layer material | Stainless steel wire mesh or sintered felt | Design pressure | 10Mpa |

| Assemble type | thread assemble or weld type | Operating temperature | 310ºC |

Industry Application

Company Profile

Certifications

Attend fair

FAQ

Q: What is a pleated stainless steel filter element?

A: It's a durable filter with folded steel sheets for efficient filtration in various applications, due to corrosion resistance.

Q: Where are these filters used?

A: They're used across industries, from industrial processes to food manufacturing, due to stainless steel's versatility.

Q: How do pleated filters work?

A: Pleats increase surface area, improving particle capture and filtration efficiency in diverse fluid systems.

Q: Can these filters withstand high temperatures and pressures?

A: Yes, their design and stainless steel material enable them to endure demanding conditions effectively.

Q: Are they reusable?

A: Yes, they can be cleaned and reused, which enhances their cost-effectiveness and sustainability.

Q: Are pleated filters compatible with various fluids?

A: Yes, stainless steel's chemical resistance makes them suitable for a wide range of fluids and chemicals.

Q: How do I install and replace these filters?

A: Installation is straightforward; follow guidelines provided. Replacement is simple and ensures continuous filtration efficiency.

Q: How do I select the right filter for my application?

A: Consider flow rate, filtration needs, and compatibility factors to choose the optimal filter element for your system.

Q: How often should I clean the filter?

A: Clean when pressure drop or flow reduction is noticeable.please clean them after switching the filter chamber.

Q: Can I use compressed air to clean the filter?

A: In some cases, compressed air can help remove larger debris, but avoid excessive pressure to prevent damage.

Q: Can I reuse filters after cleaning?

A: Yes. Correct cleaning procedure could extend the filter element service life up to 16 cycling.

Q: What's the impact of not cleaning the filter?

A: Neglecting cleaning leads to reduced flow, decreased filtration efficiency, and potential equipment damage due to increased pressure.

Q: Are there professional cleaning services available?

A: Yes, some manufacturers or third-party services offer specialized cleaning for complex filters; inquire about service availability.We also provide the filter element cleaning system .Please contact the sales on-line.

>>

Efficient Wheat Straw Round Baler Reliable and Durable Farm Machinery

>>

Fully Automatic Two RAM Baler

>>

Liansu CE standard factory Custom Color Small Screw Compact injection molding plastic masterbatch volumetric doser

>>

China Manufacturer Diesel Powered Hay Cutter Stalk Cutter Chaff Grass Cattle and Sheep Feed Chopper

>>

Hand Made 3D Fashion Designs for Dress

>>

Aohua Factory Sales IP67 Waterproof Cable Connector M12 4pin Male Female Plug/Socket with Cable for Stage Light Waterproof Cable

>>

Ground Roller with Zerk Fitting for Roll off Container Tanks

>>

Small Animal Poultry Chicken Feed Pulverizer Machine

>>

Hydraulic pump Repair parts for Ford 7600 E1NN600AB 83928509 83996272

>>

Taijia High Precision NDT Concrete Rebar Corrosion Detector for Building Tool concrete steel corrosion detector

>>

China original manufacturer rework station for bga repair parts wds-650 rework bga station for laptop motherboard

>>

Suspended Platform Gondola for Window Cleaning Machine

>>

Car parts Front bumper Inner reinforcement aluminum 52131-48050-D5 for Lexus RX 300/330/350 2003-2016

>>

Sandblasted Transparent U Shaped Glass U Channel Tempered Glass

>>

Functional medical Insomnia physiotherapy instrument to help sleep problems

>>

High quality Custom cotton white polo shirt

>>

Luxury Designer Heart Warm Crochet Fleece Cozy Knitted Checkerboard Decorative Blanket Throws

>>

Transparent Safety Plastic Cover Full Face Shield

>>

Foundry Iron Metal Casting Machinery

>>

High Quality Js500 Double Axle Industrial Cement Electrical Concrete Mixer