US$0.85

1,000-4,999 Square Meters

US$0.83

5,000-19,999 Square Meters

US$0.80

20,000+ Square Meters

Basic Info.

Breaking Tensile Force

>900n/5cm

Maximum Themperature

230c

Transport Package

30.6kg/Roll

Specification

184*25*25cm

Production Capacity

8000000000m2/Year

Product Description

Polyamide 66 Peel Ply Fabric for Vacuum Demolding 85g is a kind of plain woven fabric using tiny high strength polyamide 66 filament,through complex manufacturing processes from fiber drawing,cloth weaving,surface treatment,cutting,re-windering.Generally it is used for pumping vacuum infusion of resin composite material parts(fiberglass composite material parts,carbon fiber composite material parts and para armid composite material parts,even their hybrid parts),after curing,the demolding is easy and the surface of thermo-setting plastic parts is clean and tidy,better for the next process,like polishing,painting,etc.

SPECIFICATIONS:

| MODEL: | XGPA66-85-1.8 |

| DENSITY: | 85g/m2 |

| WEAVE: | plain |

| FIBER TYPE: | PA66 |

| BREAKING TENSILE FORCE: | >900N/5cm |

| FIBER DISTRITUTION: | 19*15pc/cm |

| THICHNESS: | 0.15mm |

| SIGHT THREAD COLOR: | red |

| SIGHT THREAD DISTANCE: | 30mm |

| MAXIMUM THEMPERATURE: | 230ºC |

| OIL CONTENT: | <0.5% |

| ROLL WIDTH: | 180cm |

| ROLL LENGTH: | 200m |

ADVANTAGES:

1.high strength:breaking tensile strength is high,not easy peering,

2.high temperature resistance:withstand temperatures about 230 ºC,

3.stablity:anti-pulling and avoid distortion.

4.smooth surface:demolding with nice surface composite curing parts,

5. long width:width can reach 1800mm,easier for large curing parts.

APPLICATIONS:

1.prepreg:fiberglass fabric prereg,carbon fiber fabric prepreg,balsalt fiber fabric prepreg,para aramid fiber fabric prepreg,

2.wet lay up:room temperature curing parts demolding ply.

3.oven curing:prefabricated part oven curing,autoclave curing,

STORAGE:

The peel ply fabric should be keep dry in their original bags and stored in a suitable place,preferably at room temperature with 35-65% relative humidity.Avoid the sun, rain and fire.

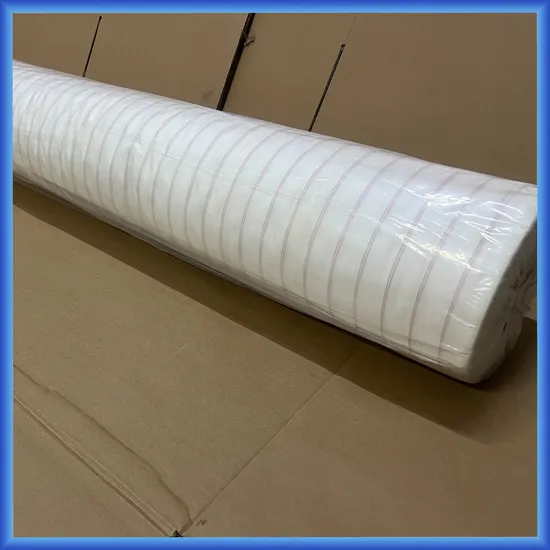

PACKAING:

PRODUCT DETAILED IMAGES:

>>

MID-Length Down Jacket High-Performance Warmth & Stylish Design Made in China

>>

portable combine harvester combine harvester thresher rice wheat reaper

>>

Express Delivery From China to France

>>

pp/pe/ SMS Blue Standard Sterile Disposable Surgical Gown For Medical

>>

Aluminum Ring Mesh Metal Curtain For Decorative

>>

U95-33 Cutting Picks for Coal Mining Shearer Machine

>>

Best Price Custom Sand Casting Gusseisen

>>

Roofing Ceiling Frame Galvanized Main Channel C Shape Furring Steel Profile Cold Roll Forming Machine

>>

bedroom door designs door design,wooden single door designs,wood glass door design

>>

S315mc S355mc S420mc S460mc S500mc S550mc S600mc S700mc S650mc Laser Cutting Hot Rolled Steel Plate

>>

fresh fruit protection packaging plastic grape transparent bag

>>

Taijia Portable Integrated rebar scanner for construction, precision rebar scanner

>>

Greetmed Cheap prices dental equipment chair unit

>>

Horizontal Removable Element Woltman Multi Jet Digital Plastic Cast Iron Water Meter

>>

Custom CNC Machining High Quality Carbon Structural Steel Parts

>>

Lvyin Mu 28-0-0 Nitrogen Fertilizer Solution Methylene Urea Foliar Fertilizer Slow Release Fertilizer

>>

Netherlands Brand Delem Hydraulic Folder 200t3200mm with Da69t Controller

>>

Winding Slip Ring High Voltage Motor

>>

Professional Submersible Ultrasonic Transducers Immersible Underwater Ultrasonic Transducer Vibrator Plate

>>

by Strong Export Wooden Case. Full Printing Spot UV Varnishing Machine