Basic Info.

Forging Work Steps

Preliminary Working>Press Fit>Finish Machining

One-time Molding

Not One-time Molding

Warranty

Product Life Based on Production Environment Habit

Precision

Based on Customed

Transportation

by Air/Sea/Railway

Delivery

According to The Order Quantity

Specification

Custom box gauge

Production Capacity

100000PCS

Packaging & Delivery

Package Size

32.00cm * 24.00cm * 25.00cm

Package Gross Weight

10.000kg

Product Description

Product Description

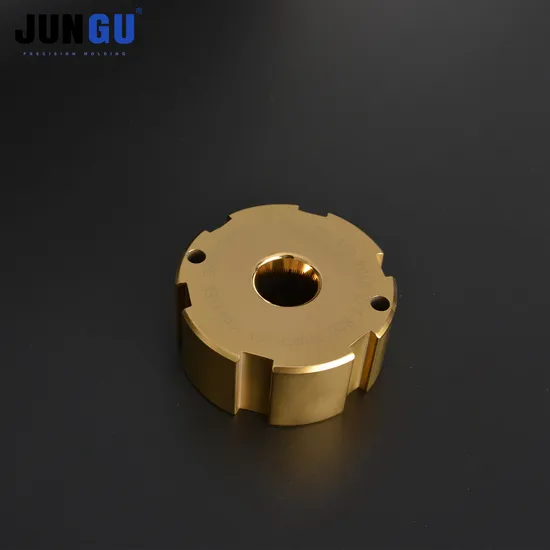

High precision metal die bolt used for carbide Tungsten carbide die bolt is mainly composed of tungsten carbide insert and high speed steel die case. Tungsten carbide has the characteristics of high strength, high abrasion resistance, high hardness, high temperature resistance, etc., which can effectively improve the service life of the mould and at the same time, it can also meet the production of different materials of nuts. Our nut dies are of good quality, high precision and quick delivery. We are looking forward to cooperating with you!

| Product Name | Die bolt/die bolts/bolt die/die punch |

| Material | Tungsten carbide and High-speed steel |

| Accuracy | High-precision(0.005) |

| roughness | RA0.1 |

| Advantage | High hardness , high wear resistance,high heat-resistance |

| Lead time | Shortly lead time(around 15 days,10 days are available for a small number of urgent order) |

| Service | Customization,Design and optimization capability for improvement of mould life |

| Application | High strength automotive fasteners, auto parts, engineering forging parts, rail transit rivets,

aerospace rivets, tensile mold products, and all kinds of standard cold heading molds. |

| Certification | ISO9001:2015 |

| Processing methods | Cold heading, warm heading, hot forging, cold extrusion, stretching. |

| Equipment | CNC Lathes, CNC inner hole grinding machines,

CNC cylindrical grinding machines, CNC Wire cutting,etc. |

Company Profile

Founded in 2014, JUNGU is a professional precision fastener mold manufacturing enterprise integrating design,production, sales and service.

Our factory covers an area of 10000 square meters and have 120 employees,6 technicians,12 engineerers,5 people after sale sevice team and 178 equipments. The company mainly produces cold heading molds, including multi-station boltand nut molds, cold extrusion molds, and vertical forging

molds.

Suzhou Jungu precision mould Co.,Ltd is a professional fastener mold manufacturer with 10 years of experience in molding industry.We have advanced production lines and a team of experienced stuff. We provide a full range of solutions for all kinds of cold heading mould, including multi-station bolt and nut mould, cold extrusion mould, vertical forging mould.

Throughout the entire production process,we take strict quality control measures including raw materials inspection,production process monitoring and final product testing.

We have built cooperation with many brands around the would.Such as EJOT,NEDSCHROEF,UNISTEEL,NM GROUP and etc.

For many years, it has been in a leading position in the industry and was the first to pass the IS09001 quality management system certification. Backed by strong technical strength and talent advantages, Jungu strives to provide customers with cost-effective products and services.

How to Satisfy Customers is our eternal pursuit.

Customers

We have built cooperation with many overseas clients in the word.

Certifications

Packaging & Shipping

FAQ

1. Q: Are you a manufacturer or a trade company?

A: We are a professional manufacturer of fastener mould with 10 years of experience in this industry.

2.Q: What is a cold forging die, and how does it function in the manufacturing process?

A:A cold forging die is a specialized tool used to shape metal at room temperature through high-pressure deformation. It functions by applying force to a metal blank, causing it to flow into the desired shape without heating the metal.

3.Q: What materials are typically used to manufacture cold forging dies, and why?

A:Cold forging dies are typically made from high-grade tool steels like H13 or SKD61, or carbide. These materials are chosen for their exceptional hardness, wear resistance, and toughness, which allow them to withstand the intense pressures involved in cold forging.

4.Q:What are the main advantages of using cold forging dies in production?

A:The main advantages include high-strength components, cost-effective mass production, superior surface finish, and reduced energy consumption compared to hot forging, making it environmentally friendly.

5.Q: What advantage do you have?

A:We mainly have three capabilities: Professional mould simulation development and design capability. High-precision and high stability mould manufacturing capability. Optimization capability for continuous improvement of mould life. 6.Q:Is it acceptable to visit your factory?

A:Welcome to our factory for a visit. Our factory is located in Taicang,shouzhou city,jiangsu province,China.The traffic is very convenient.

Thank you very much!

>>

Durable Polyimide Fiber Insulation for Extreme Heat Applications

>>

I9 11th/12th13th Generation RAM 8GB/16GB/32GB Hard Drive 1t/2t Windows10/ Linux OPS PC

>>

High Hardness Plastic Boards Custom Nylon Board Machined Cheap Plastic Sheet extruded nylon sheet

>>

Newly Designed Multifunction Small Glove Machine

>>

Kobramax RADIATOR COOLING FAN For NISSAN 214814EB0A For RENAULT 214814EB0A auto mechanic

>>

Custom OEM 1ft 3ft 50ft UTP Four Twist Pairs CAT6 Ethernet Network Lan Cable

>>

MAICTOP auto parts rear bumper step for lx570 black hot sale rear bumper pedal

>>

EPC05 Phone Case Cover, Mobile Case Cover

>>

LED Plant Growth Light Full Spectrum PAR20PAR30PAR38 Indoor Succulent Pot Plant Fill Light

>>

Front Wheel Bearing For Hyundai Elantra & Gt 51720-0q000

>>

Taijia schmidt Rebound Test Hammer for Mechanical Schmidt Concrete

>>

Metal Stamping Tool Typical Parts Seating Structure Roof Chassis Floor etc

>>

GYC autoclave sterilizer price for canned food

>>

Factory Wholesale Cylinder Whippy Cream Charger Chargeurs De Creme Dessert Tools 640g Smart Whipped Cream Charger

>>

High Quality Pet Strap Band Pallet Strapping Belt Raw Material IV Improve Machine

>>

Anti-UV Wood Plastic Composite WPC Decking Outdoor 150*22mm Flooring

>>

18V Electric Battery Wood Metal PVC Pipe Reciprocating Saw (FMGT-21)

>>

Mr-20g Drill Sharpener Automatic Electric Sharpening Diameter 3-20mm Drill Bit Grinding Machines

>>

Industrial Plastic Crusher PET Bottle Crushing Machine Price

>>

28110-2V500 Air Cleaner For Veloster