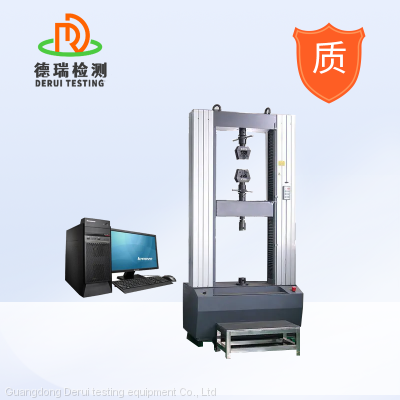

Product Details

Product Description

Product Description

Specification

| Frame capacity | 2000kg |

| Load cell brand | Germany brand load cell for high accuracy, |

| 2000kg (500,1000kg are optional) |

| Load accuracy | 0.5% F.S |

| Control system | PC with windows 7 system |

| Motor | Panasonic servo motor w/AC variable speed drive system, high-precision mechanical ball screw rod |

| Force reading | kgf, Ibf, N, KN, T etc |

| Vertical test space | 1200mm including fixture |

| Horizontal test space | ≤400mm |

| Test speed | 0.1~500mm/min (adjustable) |

| Software | TM 2101 |

| Curves display | Load- elongation, Elongation-time, Time-elongation, Stress-strain |

| Data display | Max. force, speed, sample information, strength(Kpa, Mpa, N/mm, N/mm2) etc… |

| Safety features | E-Stop |

| Over-load protection |

| Upper and lower limit switches |

| Load sensor with automatic retreat |

Widely used in various industries ASTM standard testing

Metal Processing and Manufacturing Industry: In the process of metal raw material procurement and quality control of metal products, it is necessary to test the tensile strength of metal materials according to ASTM standards. Our testers can accurately test all kinds of metal materials, such as bars, plates, pipes, etc., to ensure that the products comply with the relevant ASTM standards and quality requirements, to improve the competitiveness of the products in the international market, and to provide strong support for the quality control of metal processing and manufacturing enterprises.

Plastics and Rubber Products: Plastics and rubber products manufacturers often need to conduct tensile property tests on raw materials and finished products in accordance with ASTM standards during the process of product research and development and quality inspection. For example, according to ASTM D5034 “Test Methods for Tensile Strength of Fabrics” for rubber fabrics, this tester can accurately determine its tensile strength and other performance indicators to help enterprises optimize product formulations and production processes to ensure product quality in line with international standards to meet domestic and international market demand.

Research Institutes and Testing Organizations: It is crucial for research institutes to follow the ASTM standard in their material science research and for third-party testing organizations to provide professional testing services. Our ASTM tensile strength testers provide them with high-precision and reliable testing means, which can be used to explore the properties of new materials, validate theoretical models, carry out comparative research on materials, and issue authoritative test reports, which promotes the development of the field of materials science and plays an important role in international scientific research cooperation and testing services.

Aerospace, automobile and other high-end manufacturing industries: Aerospace and automobile and other high-end manufacturing industries have extremely stringent requirements on material performance, which must comply with international authoritative standards. In the selection of materials and quality testing of parts in these industries, our testing machines can test all kinds of high-performance materials according to ASTM standards, such as aluminum alloys for aerospace and high-strength steels for automobile engines, etc., to ensure that the performance of materials under actual use conditions meets the standard requirements, providing a solid guarantee of product quality and safety for the high-end manufacturing industry.

ASTM standard tensile strength tester maintenance core points

Maintaining the ASTM standard tensile strength tester is of great significance to ensure that its performance is accurate and reliable, which is related to the compliance of test results with the standard and the service life of the equipment, and provides stable support for material testing work. The following are the core maintenance points.

I. Maintenance of key components

1. Force transducer: Wipe it with a clean soft cloth every month to remove dust and oil, and do not use corrosive cleaners. Every six months or a year in accordance with ASTM standards, calibrate with high-precision weights, compare the tester force value with the actual value of the weights, through the calibration software to adjust the reference, maintain ±0.5% FS accuracy, and contact a professional overhaul when there is a large deviation.

2. Displacement sensor: check the installation and cable every week, manually move the parts to observe the value changes. Quarterly laser interferometer calibration accuracy, compare the set displacement with the actual measured value, exceeding 0.001mm resolution deviation, recalibration or replacement.

3. Drive system: apply special grease on the ball screw every 2-3 months, check the motor cooling fan. Monthly check the drive belt, coupling, loose, wear and tear in time to ensure stable transmission of power.

Second, software system maintenance

1. Data backup: Backup the data of test, calibration and user settings to mobile hard disk or cloud disk every week to prevent equipment failure or data loss.

2. Software update: Pay attention to the manufacturer's update information, back up data before updating, and operate according to the instructions to ensure that the system is optimized, loopholes are repaired, and adapted to the latest ASTM standards.

3. Virus protection: Install antivirus software and check it regularly, disable unidentified removable storage devices, and turn on the firewall to ensure system security.

Overall maintenance of the equipment

1. Appearance cleaning: Wipe the appearance with a damp cloth every day, clean the operation panel regularly, and apply antirust oil to the metal parts appropriately.

2. Operating environment: the equipment is placed in a dry, clean place, temperature 15 - 30 ° C, humidity 40% - 70%, to avoid adverse conditions, installed in a stable workstation.

3. Safety protection: Check the protective door, door lock and safety sensor every month to ensure that the equipment stops when the protective door is opened, and also check the protection function of overload, limit and leakage, and repair or replace the invalid device in time.

>>

New Full-Automatic Paper Element Oil Air Filter Full Auto Knife Pleating Machine

>>

Low Price Custom Dyeing Heavy Silk Fabric 135cm Width Mulberry Silk Viscose Spandex Charmeuse Natural Fabric for Women Luxury Garment

>>

China Factory Yn Qsz 2400 Silage Corn Combine Harvester

>>

35CrMo square steel tube seamless profile pipes cold drawn round tubes professional manufacturer

>>

12 Bamboo bread tong/bamboo wooden kitchen tongs,bamboo toaster tongs

>>

Food Sanitary Stainless Steel Electric Jacketed Kettle with Agitator

>>

XTIOT XT2003C 2D Codes Scanner Module Barcode QR Code Reader With LED Indicator Small Size Easy To Integrate

>>

Professional Manufacturing Agricultural Machinery Rotary Tiller with High Quality

>>

High Quality Cone Crusher for Gold Ore Aggregate Concrete Granite Mining Crushing

>>

Garden Cultivator at Tractor Rome Cultivator Farm Machine Subsoiler and Ridger

>>

Aluminum Supplier French Style Luxury Double Panel Aluminium Frame Sliding Glass Windows

>>

Extra Large Clinic Salon Reception Counter Desk

>>

Cryogenic storage Tank for LNG with ASME/GB Standard

>>

Yonthin Professional Embroidery Machine Computer Embroidery Machine Embroidery Making Machine

>>

S5731-S48P4X 02353AJH S5731-S Series 48*Poe+ 10/100/1000base-T Ports+4*10ge SFP+ Ports Network Switch

>>

Plastic Car Cleaning Wheel Brush Tyre Brush (CN1823)

>>

MEMS 1x8 Fiber Optical Switch —xionghua

>>

CE standard Made in China Superior Quality Industry automatic plastic PVC PE PET doser machine gravimetric

>>

Customized Stainless Steel Plate Perforated Sheet Metal for Conveyor Belt

>>

custom size side guesst BBQ Charcoal Briquette charcoal bag 10kg