|

US$40,000.00-45,000.00

|

1 SET

(MOQ)

|

Basic Info.

Automatic Grade

Automatic

Certification

CE, ISO9001: 2000

After-sales Service

1year

Transport Package

Wooden Box

Production Capacity

50m/Min

Product Description

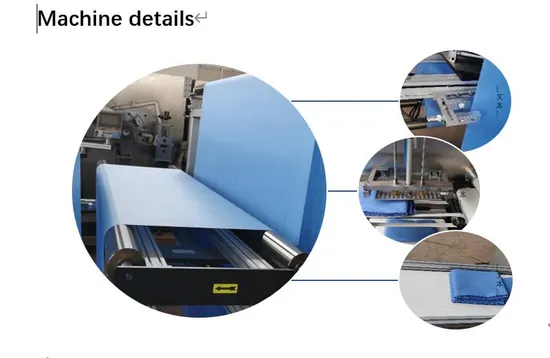

NONWOVEN BED SHEET FOLDING MACHINE

Equipment Introduction Equipment requirements: The device can process all kinds of spunlace non-woven,hot air fabric, hot-rolled fabric; acupuncture cloth, spunbond fabric, SMS, paper-plastic and other raw material. Equipment working principle: Longitudinal folding→cutting length automatically→Transverse folding→output automatically→Product stacking, the whole line complete automatically. Width of raw material under 2000mm Folded width longitudinally arbitrary adjustable, the product Cutting length can be adjusted between 350-3000mm, length error of ± 1 mm. Transverse folding: one half ,one- third, one -quarter, one -sixth, one-eighth The machine adopts the cylinder to promote the material and tension control automatically, without manual operation All the drives use the imported servo motor, high precision Touch screen control, only need to enter the data can change the specs, easy to operate. Electronic-control is touch screen man-machine interface operation,built-in production time,counting,a preset number of automatic shutdown, etc. Entire delivery system, strong, durable, non-polluting; Electrical wiring specifications and reasonable, elegant, easy to operate.

Technical parameters:

2.1 Supply Voltage: 380V 50HZ

2.2 Power: 8.5KW

2.3.Weight: 4000kg

2.4.Speed: 0-60 m / min

2.5.Dimensions: 10300 * 2400 * 2150mm

2.6.machine color: silvery white

Equipment configuration list:

3.1 Servo drive: Delta (Taiwan) 5sets

3.2 Gear motors: Yongkun (Taiwan) 1set

3.3 PLC: Delta (Taiwan) 1set

3.4 Motion Controller: Delta (Taiwan) 1 set

3.5 Touch screen: Delta (Taiwan) 1set

3.6 Sensor: Omron (Japan) 3sets

3.7 Inverter: Delta (Taiwan) 1set

3.8 Low-voltage electrical: delixi

3.9 Air shaft: 1set

3.10 Cylinder: airtac 1set

Machine structure Description

The host by the channel steel welded together, solid and firm, surface painting, The feeding part is aluminum alloy rack, the appearance is beautiful and will not get rusted permanently.

Electronic control system

5.1 PLC control system, touch screen man-machine interface operation, easy to operate, humanized design

5.2 Through the man-machine interface to adjust speed, the size of the finished product ,and Stacking quantity.

5.3With Chinese and English operator interface, easy to operate

Installation and terms of Service

6.1 we provide door to door service for domestic customers, foreign customers need to install the machine by themselves. Our engineer at the request of foreign customers can door-to-door service, but users are responsible for accommodation, round tickets visa fees and so on (domestic except). And pay our engineer 100USD one day

6.2 The seller is responsible for equipment packaging costs, use FOB export situation

6.3 Random with common wearing parts and special tools

6.4 After leaving Shanghai port the buyer is responsible for the freight, insurance premiums and unloading

Warranty scope and manner

7.1.1 Since user as the date of buy is responsible for one year warranty.

7.1.2 warranty item: machine transmission and electronic control system

Warranty manner

7.2.1 If some parts damaged, users can disassemble send manufacturer or repair the exchange.

7.2.2Our engineer at the request of customer can door-to-door service, but users are responsible for accommodation, round tickets visa fees and so on (domestic except).

In the following circumstances, our factory is not responsible for warranty, execute collect fees repair:

7.3.1. Artificial damage, such as the machine damage cause by foreign body in fall.

7.3.2. Users without manufacturers agreed to repair itself or has been disassembled.

7.3.3. Users without changing accessories etc.

7.3.4. Customer production voltage instability caused electric damage.

7.3.5. The user handling of corruption.

Considerations

8.1 The machine main components should be checked regularly, Such as welding and cutting bearing working case, filling oil appropriately to ensure that it is working properly.

8.2 Periodically check the wear of the welding, Appropriate adjust the pressure, In the case of guarantee welding well, make the pressure minimum.

8.3 Each unwinding trays tension should be checked in order to adapt to the production needs.

8.4the cutter pressure should be appropriated, otherwise easily lead to a situation such as knife fight

free parts

9.1 wrench : 1 piece

9.2 cutter : 2 pieces

Quotes and payment

10.1payment: After 30% of the total value is paid in advance by (T/T),

The left 70% should be paid by (T/T) after you check up the finished

machine. And the cargo will be delivered after all the payment

arrives at our account.

10.2 The quote is valid: 30 days

10.3 Delivery Date: Within 30 working days after receipt of prepayment from customers

Folded width:under 30cm

material width :under2000mm

>>

Hot Sale Six Sides Wood Automatic CNC Boring Drilling Machine for Woodworking

>>

Factory Direct Supply Folding Sliding Door System Aluminum Glass Bifold Door

>>

china solid wood single entrance door mahogany houses interior hotels entry wooden doors

>>

Silo Feeding Systems Bulker Unloading Pneumatic System

>>

Multifunctional Vegetable Fruit Basket Wire Lightweight Metal Organizer Rack Storage Basket for Kitchen Counter

>>

Taijia TEM-620XH reinforcement testing rebar detector scanner price rebar scanner and cover meter

>>

Newest products replacement car hood-steel for model T33 Rogue 2021

>>

Factory wholesale waterproof pe ce oversleeve

>>

755nm picosecond laser tattoo removal 808 nm diode laser hair removal machine

>>

Mopa Color Laser Marking Machine for Stainless Steel Cooper Brass Chromium Nickel Molybdenum Alloy

>>

SFH6X1650 Double Row Joiner

>>

Precision-Cut Polymer Granulator Blade for Industrial Applications Reliable Pelletizing Knife

>>

640X512 50mm Dual Lens Professional Infrared Night Vision Binoculars Thermal Long Range

>>

Bto Gun Grey Shower Hidden Hidden Into Wall Recessed Inlay Embedded Wall Row Hidden Shower

>>

Room Modern Vanity Cabinets Set Bathroom Cabinet Bathroom Washbasin Cabinet

>>

Custom Wall Mount Aluminium Brushed Hospital Sign with Braille

>>

1000mt Aluminum Extrusion Machine Can Be Designed According to Customer Requirements

>>

Semi Automatic Concrete Qtj4-26c Automatic Block Machinery Machinery Price

>>

Original 5G WIFI Repeater 2.4G 5G 1200Mbps Signal Booster Wifi Extender WIFI Antenna Dual Band 5G Wireless Signal Repeater

>>

Slake Durability Apparatus at Best Price