|

US$25,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Model NO.

swiss lathe machine

Processing Accessory

Chuck CNC Lathe

Guide Rail

Horizontal Guide Rail

Tool Holder

Double-tool Holder CNC Lathe

Power Source

Hydraulic Pressure

Automatic Grade

Automatic

Certification

GS, CE, RoHS, ISO 9001

System

Fanuc 0I TF-Plus /Syntec 220tb

Max.Rpm

Main8,000min-1/Sub8,000min-1

Main Spindle Stroke

210mm

Rapid Traverse Speed

32m/Min

Back End Tools

4X [20-Er16]

Size

2760mmx1564mmx1882mm

Transport Package

Standard Packin

Specification

2760mm-1564mm-1882mm

Production Capacity

50000/Year

Product Description

Product Description

Unveil the extraordinary prowess of the Swiss-style lathe, renowned in the industry as a CNC automatic lathe, designed for ultimate precision and versatility. This cutting-edge machinery is a powerhouse, offering an extensive array of operations such as tapping, milling, drilling, and turning. Its revolutionary dual spindles, complemented by an ingenious double Y-axis, propel it to perform simultaneous processing, significantly slashing processing times. At its core, this lathe excels in the mass production of intricate, bespoke components, with a special focus on precision hardware and uniquely shaped shafts.

Product Parameters

| Items | SX325 |

| Mechanic | System | FANUC 0i TF-PLUS | SYNTEC 220TB |

| Max.RPM | Main8,000min-1/Sub8,000min-1 | Main6,000min-1/Sub8,000min-1 |

| Max.Turning Diameter | φ32mm |

| Main Spindle Stroke | 280mm |

| Rapid traverse speed | 32m/min(X1:24m/min) | 24m/min |

| Tools | O.D Tools | 6X [16×16] |

| I.N Tools | 5X [φ20-ER16] |

| Cross Driven Tools(integration) | 4X [ER16] |

| Back end tools(fixed) | 4X [ER16] |

| Motors | Main | 5.5/7.5KW | 5.9KW |

| Sub | 1.5/2.2KW | 3.9KW |

| Cross | 0.55/1.1KW | 1KW |

| Drive | 0.75KW | 1KW |

| Coolant | 0.9KW |

| Others | Coolant tank capacity | 200L |

| Lubrication tank capacity | 1.8L |

| Central Height | 1,000mm |

| Weight | 3,800Kg |

| The size (L×W×H) | 2581×1563×1791mm |

| NC NC Control | /Controllable Axes | 7axis/4axis |

| LCD | LCD 10.4" |

| System standard parameters | Standard |

| Rigid tapping | Standard |

| Hand wheel | Standard |

| / Synchronous/hybrid control | Standard |

| Helical interpolation | Standard |

Items |

| Standard units |

Hand wheel | /C+

Main/Sub axis C + brake |

Floodlight |

The product output device |

Transformer |

Centralized lubrication system |

Three color light |

Synchronus rotary guide bush holder unit |

C:0.001°

C axis resolution: 0.001 ° |

Auxiliary shaft workpiece ejection device |

M

Air blow on Sub spindle | Cooling box |

| 0ptionanl units |

Bar feeder |

Long after loading device |

Chip conveyor |

Rectangular power seat |

Oil cooler |

Dynamic seat adjustable Angle |

Gun drill |

After the end of the quick change perspective |

Oil mist collector | 2[ER16]+1 [ER16]

2axis eccentricity tools (rotating)+1axis (fixed) |

High pressure pump | 3[ER16]

3axis eccentricity tools (rotating) |

Thread whirling rings | 3+[ER16]

Back end tools 3axis (rotating)+ 1 axis (fixed) |

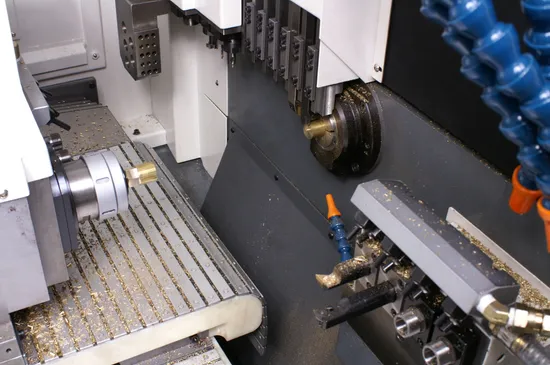

Detailed Photos

Application

Applications of Swiss Machining

Swiss machining began in the illustrious Swiss watchmaking industry but has since expanded its reach to numerous sectors. Industries currently leveraging this superior technology include:

1)Aerospace

The aerospace sector reaps immense rewards from the precision parts crafted through Swiss machining. Aluminum alloys and steel are prominently featured in the manufacturing of essential components like fans and fasteners, confirming Swiss machines as indispensable to aerospace innovation.

2)Medical devices

In the realm of medical technology, Swiss-style lathes are invaluable for creating delicate components. The unmatched precision they afford is crucial for crafting surgical instruments and implants, underscoring their transformative role in advancing medical device manufacturing.

3)Electronics

As modern electronics continue to shrink and increase in complexity, traditional lathes struggle to meet these demands. CNC Swiss machining emerges as the advanced solution, adept at fashioning connectors, pins, and numerous intricate electronic components with unrivaled skill.

4)Automotive

Swiss machining plays a pivotal role in the expansive automotive industry, contributing to recent mechanical breakthroughs. It is instrumental in fabricating the smaller, intricate components that drive innovation in modern automotive design and functionality.

Automakers are harnessing this technology to produce key parts such as suspension components, carburetor covers, and engine elements, enjoying benefits like lower production costs, optimized manufacturing workflows, and heightened production agility.

Our Advantages

1. Professional Supplier: Rely on our seasoned team, passionate about delivering top-tier precision machinery solutions specifically crafted to suit your requirements.

2. Best Quality: Embrace unparalleled quality standards that assure dependable operation and superior performance, embodying our unwavering dedication to quality excellence.

3. Best Service: Delight in exemplary customer service, where your satisfaction is paramount, ensuring a smooth experience from initial inquiry through to product delivery.

4. Best Price: Take advantage of our competitively priced solutions that offer remarkable value, with no compromise on quality or service.

Packaging & Shipping

FAQ

1.What products do we have ?

Machine :laser engraving machine ,laser cutting machine ,laser welding machine ,laser marking machine /cnc lathe machine ,swiss type cnc lathe machine ,cnc machine center

2.Why Choose us ?

1)Faster delievery time

2)Full set of production equipment

3)Any third party test can be accepted

4)Payment terms are more flexible ,both TT and LC can be accepted

5)Perfect Pre-sale and After-sale services can be provided within 24 hours online

3.What is the best advantage do we have ?

Best Quality ,Best service ,Best price

>>

OEM Good Service Stamping Press Tool Manufacturers ABS PC PP PVC PE PA PS POM Customized Professional Steel Stainless Die Casting Molud

>>

High Performance Electrical Parts Vvt Valve Variable Timing Solenoid 463133B170 46313 3B170 46313-3B170 For Hyundai

>>

Plastic Granulator Cutting Machine with Rotary Knife Cutter

>>

Portable Plastic Car Body Repair Ultrasonic Spot Welding Machine Welder By Points

>>

High Quality Otesaly 1ml Derm Lines Hyaluronic Acid Injectable Dermal Filler for Fine Lines

>>

flat exterior wrought iron mother and son door grill with 2 sidelights

>>

Modern Outdoor Pool Tile Grey Slate Look Tiles

>>

China Manufacturer-Holo PVC Conveyor Belt Splicing Machine

>>

Hot Sale 10.1 Inch Capacitive IPS Touch Screen with Driver Board HDMI Industrial LCD Monitor for Raspberry Pi

>>

Wholesale boxing mittens custom mma gears manufacturer

>>

High Strength Hydraulic Large Deformation Forging Plate Leveling Machine

>>

Premium Quality Dehydrated Ginger Supplier Dry

>>

Safe and Reliable Pedestal Stand Oscillating Electric Portable Air Circulating Fan

>>

(9.00X15.3, 13.00X15.5) Flotation Wheel, Implement Wheel for Farm Trailer/Tmr

>>

shanghai minye Aluminium alloy glass round window

>>

Car Spare Body Parts Trunk Lid Back Door For Corolla Altis 2008 ZRE152 64401-02270

>>

Custom Logo Desginer Customised Sports Low MOQ Soccer Socks

>>

Stainless Steel Lab Standard Sifters Shakers Soil Sieve Analysis Test Sieve

>>

Aluminum Handle 3D printing Stainless Steel Rescue Survival Camping Folding Pocket Knife with Belt Clip

>>

Meltblown Nonwoven Fabric Melt Flow Index Testing Machine