Product Details

Product Description

Product Description

Product Description

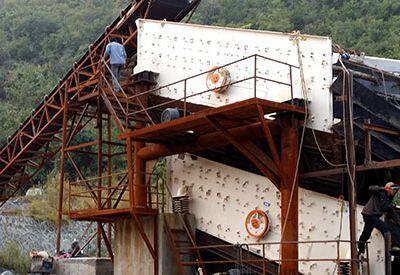

YA Series Vibrating Screen is of multiple layers and vibrating circularly. It is of longscreen line, correct to screen in all kinds

of specification products. Our VibratingScreen adopts the the adjustable cylinder exciter ,eccentric shaft and counterweight wheel. It is also of reliable structure, strong exciting force, high screening efficiency low vibrating noise, long durability, convenient maintenance, safe operation, etc. Our Vibrating Screen is widely used for screening in mines building material, transportation, energy sources, chemical industry, etc.

PRODUCT PARAMETERS

Model

| Layer of Screen

| Size of Sieve Pore (mm)

| Max. Feeding Size (mm)

| Capacity (m³/h)

| Double Amplitude (mm)

| Model of Motor

| Motor Power (kW)

| Screen Specaification (mm)

|

|

|

|

2YA1548

| 2

| 3~100

| 300

| 22~160

| 8

| Y160L-4

| 15

| 1500×4800

|

3YA1548

| 3

| 3~100

| 300

| 22~160

| 8

| Y160L-4

| 15

| 1500×4800

|

4YA1548

| 4

| 3~100

| 300

| 22~160

| 8

| Y160L-4

| 15

| 1500×4800

|

2YA1848

| 2

| 3~100

| 300

| 32~276

| 8

| Y180M-4

| 18.5

| 1800×4800

|

3YA1848

| 3

| 3~100

| 300

| 32~276

| 8

| Y180M-4

| 18.5

| 1800×4800

|

4YA1848

| 4

| 3~100

| 300

| 32~276

| 8

| Y180M-4

| 18.5

| 1800×4800

|

2YA1860

| 2

| 3~100

| 300

| 65~586

| 8

| Y180M-4

| 22

| 1800×6000

|

3YA1860

| 3

| 3~100

| 300

| 65~586

| 8

| Y180M-4

| 22

| 1800×6000

|

4YA1860

| 4

| 3~100

| 300

| 65~586

| 8

| Y180M-4

| 22

| 1800×6000

|

2YA2160

| 2

| 3~100

| 300

| 81~720

| 8

| Y200L-4

| 30

| 2100×6000

|

3YA2160

| 3

| 3~100

| 300

| 81~720

| 8

| Y200L-4

| 30

| 2100×6000

|

4YA2160

| 4

| 3~100

| 300

| 81~720

| 8

| Y200L-4

| 37

| 2100×6000

|

2YA2460

| 2

| 3~150

| 300

| 90~810

| 8

| Y225S-4

| 37

| 2400×6000

|

3YA2460

| 3

| 3~150

| 300

| 90~810

| 8

| Y225S-4

| 37

| 2400×6000

|

4YA2460

| 4

| 3~150

| 300

| 90~810

| 8

| Y225S-4

| 37

| 2400×6000

|

2YK3072

| 2

| 3~200

| 300

| 180~1300

| 8

| Y200L-4

| 30×2

| 3000×7200

|

3YK3072

| 3

| 3~200

| 300

| 180~1300

| 8

| Y200L-4

| 30×2

| 3000×7200

|

Main features:▲ The annular grooves are rivetedwhich is advanced in structure and durable in operation.

▲ Pinch plate is used to fasten the screens cloth inside vibrating screen, which is firm and easy for replacement▲Screen cloth is high in central and low in both sideswhich enables the materials to scatter onto both sides and improves the screening efficiency.▲ Adoption of high strength springs allows long service life.▲The screen cloth of high abrasive material allows extended service life.(The polyamine materials also can be used).

▲Bearings are produced by the largest manufacture nationwide(ZWZ) and SKF also can be used. The vibrator with ample clearance bearings has low noise and long service life.

▲Motors are all famous brand:customers can also specify other brands such as Siemens.

CUSTOMER SITES

Packaging and Shipping

About VANGUARD

Zhengzhou Vanguard Machinery Technology Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises. Our factory covers 110000 square meters and our products are sold to more than 100 countries, being the popular equipment in global crushing industry.

Matching of production and support system allows customers to get best service at lowest cost.

Qualification

Our products have passed ISO9001-2008 international quality management system certification and European CE certification and established a fully controlled quality management system. We are playing a leading role in quarry mining, sand making and industry powder producing fileds.

Our Services

FAQ

Q1: what will you do if the machine is broken down? Does your company supply the spare parts?

A: The Products warranty is 12 months. We will provide the technical advice and find the solution immediately for you when the machine is in trouble. And we will supply the spare parts with high quality for you at the lowest cost.

Q2: How long is your delivery time?

A: The lead time is 10-30 days. Delivery time will vary depending on the type of the machine, availability and shipping method.

Q3: Do you supply oversea service?

A: Yes, we do. Engineers available to service machinery overseas.

Q4: How about the quality of your equipment?

A: Our products are manufactured strictly according to national and international standard, and we will take a test on every set of machine before delivery.

>>

5 Axis CNC Router Machine 2030 3040 Big Size 5 Axis with Rtcp for Foam Milling Syntec System

>>

high quality hot sale the latest style auto car accessories bodykit body kit sets for LEXUS LX570 2021

>>

High Quality Red Silicone Coated Fiberglass Fabrics

>>

Factory Customized Aluminum Alloy Airboat 450HP Rescue Boat

>>

2-pocket plastic customized literature holder wholesaler Acrylic Brochure Holder

>>

Bright 201 304 Grade Stainless Steel Wire for Sale

>>

HC-O004 Testing Machine Autoclave machine Fully automatic 18L computer control with competitive prices

>>

Energy Efficient Vegetable Onion Fresh Fruit Berry Dryer Machine Price Dryer Machine for Fish

>>

Yolanda Economical Custom Design Desks L Shape Boss Office Desk Furniture Set Executive Table Bureau with Small Storage Cabinet

>>

Health Grade Seagress Tansfer Rotary Pump

>>

MAICTOP car auto interior accessories upgrade kit for lx570 2021 steering wheel dashboard cover inside kit

>>

City Electric Bike 500W 1000W for Adult

>>

Factory Direct Sales Galvanized Car Repair Gecko Expansion Bolt Wedge Anchor Bolt

>>

High-Quality Concrete Batching Machine

>>

High-Speed Woodworking Wood Drill Bit Set Milling Cutter Carving Tools Dremel HSS Woodcarving Tool

>>

Buick GL8 2.4L three-way catalytic converter replacement full set

>>

SMS45GSM Isolation Gown Long Sleeve Knitted Cuffs Blue Visiting Gown

>>

Thermal Break Aluminum Alloy Window Aluminum sliding windows AS2047

>>

Premium A4 Copy Paper 80 GSM for Sharp Printing

>>

Original KPS-600 KUKA 00-134-525 kps 600-20 KUKA robot servo drive power supply module KPS-600/20-ESC 00-134-525