|

US$5,000.00-20,000.00

|

1 Set

(MOQ)

|

Basic Info.

Model NO.

600type~1000type

Material Processed

Plastic Bottle

Computerized

Computerized

Certification

QS, GMP, ISO9001:2008, CE

Machine

Pet Bottle Washing Cleaning Plastic Recycling

Capacity

1000kg/H-3000kg/H

Suction Label Machine Powe

7.5kw*3

Solution

Clean and Dry Pet Flakes

Clean and Dry Pet Flakes

1 Year

Motor

Siemens or Other Brand

Since 1992

Can Be Customerized

Delivery Time

Within 40days

Electrical Panel

Chnt or Other Famous Brand

Transport Package

PE Film Strength

Production Capacity

50sets Per Month

Product Description

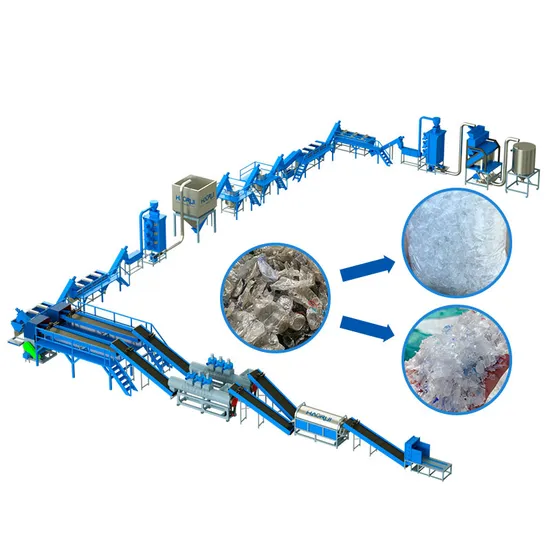

Product Overview

Multi-fuctional PET Bottle Label Remover Machine

Usage:Seperate the label of the PET bottles

The whole line comes out as clean bottles

Product Specification

Different needs and different choices, we can meet

| type | Capacity | Machine size | motor | Blade material |

| 600 | 1000kg/h | 4m(L)*1.1m(W)*2.2m(H) | 15kw | alloy |

| 800 | 1500kg/h | 6m(L)*1.2m(W)*3.45m(H) | 37kw | alloy |

| 900 | 2500kg/h | 6m(L)*1.2m(W)*3.45m(H) | 37kw | alloy |

| 1000 | 3000kg/h | 6.5m(L)*1.25m(W)*3.8m(H) | 55kw | alloy |

High label remove rate(round bottle> 99% , bale bottle> 96% )

600type 800type

900type 1000type

Details Images

Unique sharp knife flat knife design,with patent certification

High label removing ratio, and low bottle damage ratio

The machine with replaceable blades, easy replacement and save labor

Sufficient thickness for better wear resistance

All the production process is completed independently by our factory Capacity up to 3500kgs/h Unique design blade quantity and shape,with patent certification. Most hot-selling item, 98% customers gave good feedback. Don't damage bottles, reduce neck broken, reduce material loss. Good design label separation chamber, can used for wet bottle, label come out well, not block

Packaging&Shipping

Ensure fast transportation without damage

Company ProfileBaoding Haorui Machinery Manufacturing Co.,ltd was established in 1992,is a professional manufacturer and exporter that is concerned with the design,development and production of PET bottle crushing and washing machine, PP PE HDPE LDPE plastic crushing and washing machine, pelletizing machine .There are over 100 technicians in our workshops which covers 20000 square meters. Over 28 years of plastic recycling machines production experience ,enable us to be TOP3 plastic recycling machine factory in China. Our own R&D team make our machine design unique, OEM and ODM service are also welcome. Our main products include bale opener, label remover, plastic crusher, floating tank, screw feeder, high-speed friction washer , hot / cold washer, dewatering machine, pipe dryer and so on.We insist on the principle of "quality is first" and inspect the machine after producing " which make our market more popular in Domestic and over 40 sets of PET bottle washing line(four 6000kg/h capacity in Nigeria ,Ghana etc), PP PE HDPE LDPE washing line ,pelletizing machine were installed in Middle East,Africa,South America,South East, South Asia and so on

Factory

successful case

our advantages

FAQ

Q: How often are the Crusher blades sharpened?A: After continuous working at 30-40hours, the blades have to be sharpenedQ: How long does it take for changing blades-Remove and install blades?A: Depending on the worker skilled or not. Normally 2-3hoursQ: How about the rate for removing the labels by Label remover?A: Compressed bottle: more than 96% Un-compressed bottle: more than 98%Q:What's the temperature of steam washer ?A: Usually 80-90ºC ( If the temperature is over 100ºC, the Flake will be roll.so the best temperature is 80-90ºC)Q: What's the moisture after Horizontal dewatering machine?A: About 1.8%. Adopt Swedeen SKF bearing, with bearing layer on the surface of screw bladesfor longer working life.Q: How often are the Crusher blades sharpened?A: After continuous working at 30-40hours, the blades have to be sharpenedQ: How long does it take for changing blades-Remove and install blades?A: Depending on the worker skilled or not. Normally 2-3hours

>>

Hot Sale Flat Bed Hard Guide Rail High Precision CNC Turning Machine

>>

Best Price Fish Pellet Machine Fish Feed Forming Machine Dog Food Making Machine for Retail

>>

Infant Comfort Lovely Animals Guitar Shape Plastic Hand Rattle Pat Drum Musical Baby Sensory Toys with LED Light

>>

Fiberglass Pipe Filament Winding Machine

>>

Hot Galvanized Material Layer Chicken Cage for Scale Poultry Farm

>>

Good quality solid wood stainless steel material inflatable axe laser texture technology inflatable axe

>>

PVC Exam Glove Dipping Machine

>>

New design 304 stainless steel glass toothbrush metal jar lid

>>

AB 1783-ETAP1F Ethernet I/P Switch Module In Stock

>>

196-5953 TURBOCHARGER GP Caterpillar parts 3456, PM3456 TURBOCHARGER

>>

Henning Saint plastic color sorter

>>

Kr600/Kr700 Pto Gearbox Reducer Aluminium for Tractor Agricultural Power

>>

Machinery Manufacturer Plastic material Color Screw Dosing Doser automatic dosing machine

>>

Hot Sale 304# Stainless Steel Table Base Metal Trumpet Tulip Design Outdoor Living Room Bedroom-Coffee Dining Granite Table

>>

Nebula cloth pattern PU leather Material

>>

Chain Lock / Motorcycle Lock /Key Lock

>>

MAICTOP Car Front Bumper cover Fog Lamp Frame Garnish Trim For Hilux vigo 2012 52128-0k030 52127-0k030

>>

Electric Battery Knapsack Sprayer New Design Battery Easy Take out

>>

Versatile Outdoor Multi-Tool: Stainless Steel Camping Survival Knife 7 in 1

>>

4-seat electric golf cart beach car