Basic Info.

Screen Mesh

Without Screen Mesh

Grinding Equipment Type

Feed Hammer Mill

Pellet Mill Type

Extruder

Bulking Machine Type

Single Screw Bulking Machine

Expanding Method

Dry Expansion

Applicable Materials Shape

Powder

Transport Package

Container or Wooden Case

Specification

120-150kg/h

Production Capacity

200 Units/Month

Product Description

Soybean Expander/Soybean Extruding Machine/Single Screw Soybean Extruder

1. Processing method of extruded soybean/Soybean Expanding Machine/Single Screw Soybean Extruder

The main equipment for extruding soybean is the extruder, which can be divided into two types: dry puffer and wet extruder. The main difference between the dry extruder and the wet extruder is that the wet extruder has a modulator, and steam is introduced into the extruder. The initial input of wet extruder is larger than that of dry extruder, but the output per unit time is high and the energy consumption is low. The specific use of dry expansion machine or wet expansion machine, users can determine according to their actual situation.

2. Soybean Extruding Process/Soybean Expanding Machine/Single Screw Soybean Extruder

Raw material screening impurity removal crushing expansion cooling finished product packaging

In general, the production of extruded soybean flour requires the following main equipment:

1. Soybean crusher can smash soybean into soybean powder by pounding.

2. Soybean extruder: This is the key equipment for the production of extruded soybean flour. The soybean flour first enters the conditioner of the extruder, which is heated and humidified by steam. The soybean flour after steam conditioning enters the extruder from the strong feed. The function of the strong quality feeder is to prevent the materials with high heat and humidity from caking and blocking when they enter the cavity. After entering the expansion cavity, the extruder screw pushes the soybean flour forward. In the process of pushing forward, a large amount of heat is generated to make the soybean warm and mature. Finally, the extruded soybean flour is produced by the extrusion machine cavity head.

3. The water content and temperature of extruded soybean flour with high temperature and high moisture content enters into the cooler and is cooled by natural air drawn by the fan, so as to reduce the moisture and temperature of extruded soybean flour to the qualified level, so as to facilitate the storage of users.

4. Crusher: according to the needs of users, crush the extruded soybean powder to the fineness suitable for users, and finally get qualified extruded soybean powder products.

The above are the main equipment for the production of extruded soybean flour. In actual production, there are some supporting equipment. According to the different production process, the following equipment may be used: screw conveyor, elevator, pulse dust collector, brake dragon, fan, rotary grading screen, etc.

3. Detection method of extruded soybean/Soybean Expanding Machine/Single Screw Soybean Extruder

The purpose of soybean expansion is to destroy some anti nutritional factors effectively, improve its utilization rate, and make livestock and poultry get better production performance after feeding. However, if the aging is excessive, some amino acids will be destroyed. If it is over heated, the damage to lysine, arginine and cystine will be increased, and the digestibility of methionine, isoleucine and lysine will be decreased, and the food intake will be reduced. If the degree of ripening is not enough, it will seriously affect its utilization rate, so it is necessary to do a test on its ripening degree. Generally, the degree of ripening is determined by the activity of urease in soybean flour. At present, there are many detection methods, the more commonly used are pH value-added method and phenol red method. According to the Chinese feed standard, the value of urease activity measured by pH method should not exceed 0.4. Many studies have shown that the urease activity is only in the range of 0.03-0.04, and the feed effect is the best. However, it is better to use urea phenol red method to detect urease activity in the field of feed manufacturers. Therefore, the method is simple and fast, and the technical level is not high. It is easy to master, and can also achieve the purpose of detection in production, which is suitable for popularization and use.

4. Problems in the process of Soybean Extrusion/Soybean Expanding Machine/Single Screw Soybean Extruder

The quality of full fat soybean depends on good operation management and operation skills. Only by controlling the three parameters of time, temperature and humidity can the product quality be stable.

1. The quality of soybean: moisture content is 12.5% - 14%, impurity is not more than 2.5.

2. The best particle size of material entering the chamber is 3-6 mm, so as to achieve constant quality and improve production capacity.

3. In order to ensure the constant product quality, the residence time of raw materials in the chamber and the temperature in the chamber should be recorded in the production process. Generally speaking, the time of raw materials in the chamber is less than 30s, the duration of the highest temperature is 5-6s, the temperature of the best section should be 130-145 ºC, and the moisture content of the product should be below 8%. In addition, proper amount of water can be added during processing, which helps to reduce trypsin inhibitor without denaturation of lysine.

4. Cooling: the temperature of full fat soybean after extrusion is very high. It should be cooled down as soon as possible to prevent the product from over ripening and damaging the protein. It should be especially careful that the moisture content of the product after wet expansion is high, which must be fully dried and cooled to achieve safe storage moisture.

5. Parameters of Dry type Soybean Extruder/Soybean Extruding Machine/Soybean Expanding Machine/Single Screw Soybean Extruder

| Model | Capacity | Motor power | Feed power | Cut power | Screw diameter |

| HH-D60 | 120-150kg/h | 15KW | 0.4KW | 0.4KW | 60mm |

| HH-D70 | 180-250kg/h | 18.5KW | 0.4KW | 0.75KW | 70mm |

| HH-D80 | 300-350kg/h | 22KW | 0.6KW | 1.5KW | 80mm |

| HH-D90 | 400-450kg/h | 30KW | 0.8KW | 2.2KW | 90mm |

| HH-D120 | 500-700kg/h | 55KW | 1.1KW | 2.2KW | 120mm |

| HH-D135 | 800-1000kg/h | 75KW | 1.1KW | 2.2KW | 135mm |

| HH-D160 | 1200-1500kg/h | 90KW | 1.5KW | 2.2KW | 155mm |

| HH-D200 | 1800-2000kg/h | 132KW | 1.5KW | 3KW | 195mm |

Parameters of Wet type Soybean Extruder/Soybean Extruding Machine/Soybean Expanding Machine/Single Screw Soybean Extruder

| Model | Capacity | Motor power | Feed power | Cut power | Screw diameter |

| HH-W60 | 200-250kg/h | 15KW | 0.4KW | 0.75KW | 60mm |

| HH-W70 | 300-400kg/h | 18.5KW | 0.4KW | 0.75KW | 70mm |

| HH-W80 | 500-600kg/h | 22KW | 1.1KW | 0.75KW | 80mm |

| HH-W90 | 700-800kg/h | 37KW | 1.1KW | 1.1KW | 90mm |

| HH-W120 | 1000-1200kg/h | 55KW | 1.1KW | 1.1KW | 120mm |

| HH-W135 | 1400-1600kg/h | 75KW | 1.5KW | 2.2KW | 135mm |

| HH-W160 | 2000-3000kg/h | 90KW | 2.2KW | 2.2KW | 155mm |

| HH-W200 | 3000-5000kg/h | 132KW | 2.2KW | 3KW | 195mm |

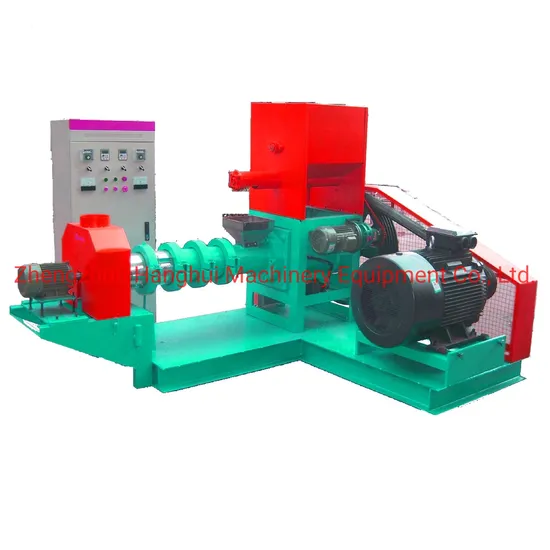

6. Pictures of Soybean Extruder/Soybean Extruding Machine/Soybean Expanding Machine/Single Screw Soybean Extruder

7. Delivery of the Soybean Extruder/Soybean Extruding Machine/Soybean Expanding Machine/Single Screw Soybean Extruder

Within 7-10 working days after deposit payment.

>>

Rubber Support for Cabling Runs and Various Application

>>

Sbt-Tp5000s Large Capacity Centrifugal Printing Ink Mixer for Material Homogeneous Effect

>>

Custom Aluminum Alloy Glass Flat Open Bathroom Toilet Indoor Doors Windows Price Of Aluminum Door To The Bathroom

>>

Discount Promotion Automatic Small Sachets Spice Chilli Powder Filling Packing Machine Price

>>

Scooter Nitrogen Shock Absorber Versatile Use Adjustable Damping More Comfortable Riding

>>

DSU14 ABB module supply

>>

G825 high quality seeders JOFAE High speed riding rice transplanter 6 rows type rice machine

>>

Portable IV Practice Kit IV Arm Model Silicone Injection Training Hand

>>

Eb Icon B30125 Electric Press Brake CNC Machine for Sale

>>

PM820-1 3BSE010797R1

>>

High Speed CNC Steel Fiber Laser Cutting Machine for Tube and Plate

>>

Absorbable or Non-Absorbable Pdo PGA 910 Silk Polydioxanone Catgut Polyester Nylon Surgical Suture Thread with Needle

>>

Reclaimer lifts AWP

>>

Factory Ceramic Classic Textured Surface Natural Stone Look Matte Finish Rustic Tiles

>>

HC-C650/1300/1600B Surface Type Slitting Machine

>>

JOHNCOO All Metal Three Colors Optional Personality Modification Baitcasting Reel Spools

>>

Room Dividers Aluminum Panels Gril Screen Partition Grille Fencing Design Partition

>>

OEM 64071 1321887 310082 334842 Auto engine cooling system aluminum truck radiator for SCA NIA R-SERIES(81-)

>>

0.5-50 Tph Salt Rotary Dryer Industry Rotary Wood Chips Drum Dryer Rotary Drum Dryer

>>

AAC Block Making Machines for The Whole Production Line