|

US$69,000.00-98,000.00

|

1 Set

(MOQ)

|

Basic Info.

Automatic Grade

Automatic

Energy Saving

Energy Saving

Certification

CE, ISO, SGS

Warranty

1 Year Except Spare Parts

After-sales Service

Lifetime After-Sales

Transmission Type

Big Gear

Raw Materials

Wood Chips, Sawdust, Timber, Trunks .Ets Wood Wast

Spare Part

Ring Die and Roller Group

Lubrication System

Automatic

Material of Die and Roller

High Alloy Steel

Installation

Manual/Video Chat/Engineer Guide

Transport Package

Iron Case/Container

Specification

2700*1700*2500mm

Production Capacity

500set/Year

Packaging & Delivery

Package Size

4000.00cm * 1825.00cm * 2700.00cm

Package Gross Weight

13500.000kg

Product Description

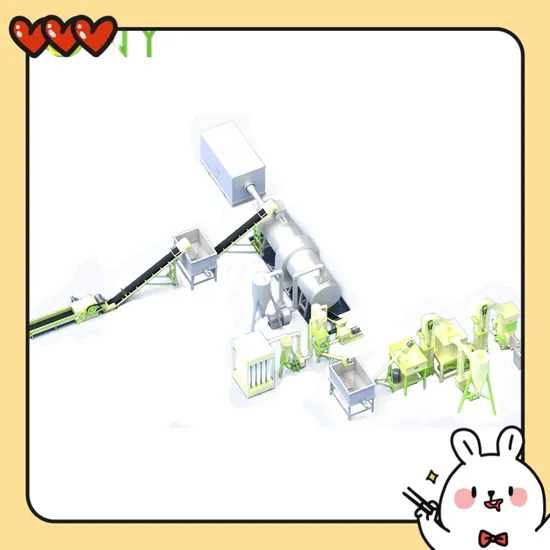

produce 3-4tons Per Hour Biomass Wood Pellet Production Line

Our Service

for

Pellet Line

| Our turn-key complete wood pellet production line get CE Certificate, guarantee the quality, machines with long service life, we offer technology support and timely after-sale service;

|

We provide all installation drawing for free;

|

We can send technicians to help installation for pellet production line abroad

|

Once purchase our wood pellet line, our engineer avaliable to service abroard.

|

Requirements for raw materials

Size:Less than 5 mm

All the raw materials must be crushed into sawdust before going

to wood pellet machine.If not, you may need a wood chipper, wood crusher.

Moisture:10-15%

Better for pelletizing high quality pellets, Final Pellets For burning

Ø6mm/8mm: household stove burning;

Ø8mm-18mm: Industrial using

Energy Level: 5kwh/kg, Compared to Oil: 1 lty oil = 2kg wood pellets

How to make pellet:

wood log is the most common raw material for making wood pellets.

So, how to design a suitable wood pellet production line with wood log as raw material?

First, a drum wood chipper is used to chip wood log into small size wood chips with 2.5-3.5cm.

After that, hammer mill/wood crusher is used to grind wood chips into sawdust (6-12mm).

Sometimes, a dryer is need ,as usually the MC of wood log is always about 30-50%,Under this condition, a dryer is need.

Then, a vertical ring die wood pellet mill machine is used to press dried, wood sawdust into good quality wood pellets. Main Processes: Crushing- Grinding-Drying- Pelleting - Cooling - Packing

1.Crushing Process: a. If the raw material is big wood log with bark,we need wood debarker machine and wood splitter machine to make the wood with small size.

b. If the thickness of raw wood material is >10mm, and >50 * 50mm(L * W), we need use the Wood Chipper to chip them into small pieces, then crush the small pieces into wood powder with diameter less 5mm by Hammer Mill (Crusher).

2.Grinding Process:

After the raw materials are crushed into smaller chips, then use our multifuctional hammer mill to grind them into sawdust. 3.Drying Process:The best moisture content to pelletizing is about 10-15%. Our Rotary Dryer is made up of Stove and Main Rotary Dryer, which can realize to reduce the moisture from 50% to 10%. Our stove is fueled by coal, which can save electricity consumption largely.

4. Pelleting Process:

Wood Pellet Mill is the most important equipment, which have the following features:

a. Perfect Turn-Key Project;

b. 24 hours continuous running;

c. Stable and Durable Equipment Function;

d. Competitive Price with Good Quality;

e. Lower Energy Consumption and Less Manpower; 5. Cooling Process:

After the pelletizing process, the temperature of the wood pellet is about 60-80 degree, and the moisture content of the wood pellet is about 14%, so we need use Cooler to reduce about 3-4% moisture, such this the wood pellet is easy to store.

But considering the feedback from some foreign clients, the local climate is very humidity; they hope to cool the wood pellet with moisture 7-8%. In order to satisfy the different need from different clients, we develop one kind of new Stabilizer Combined Cooler. 6. Packing Process:

After cooling, the wood pellet will not directly enter into the fuel process, avoiding the wood pellet affected with damp. The packing process is necessary. In this process, we assemble our domestic Semi-Auto Packing Machine to you.Customer Case

Company Introduction

TONY is a professional manufacturer and exporter engaged in the research, production, sale and service of Biomass wood pellet line, wood pellet mill, grinding equipment, crushing equipment, drying equipment, cooler and other screening, conveying equipment.Having developed the pellet machines with reliable functions, reasonable design, energy saving and high efficiency low consumption, our vertical ring die pellet mill which use special gear transmission has sold very well during home and aboard.

We always supply the most suitable machines for customers with excellent quality and competitive price.

FAQ

1.Q:Are you a manufacturer or agency?

A:We are a manufacturer with our own factory.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Zhangqiu City, Shandong Province, China. You can fly to Jinan airport and then we will pick you up(40

minutes by car) . All our clients are warmly welcome to visit us!

3.Q:How does your factory do regarding quality control?

A:"Quality is priority. We always attach great importance to quality controlling from the very beginning to the very end. Our

factory has gained CE.

If you are interested in our wood pellet production machine,please send us inquiry freely. Before quotation we need to know:1. What's the capacity you plan to produce?

2. What's the raw material?

3. What's the size of the raw material?

4. What's the moisture content of your raw materials?

5. What's the final pellet size do you want?

>>

2024 Mingju Vm-1380b CNC Machining Center Milling Machine with Two Linear & One Box Guideway

>>

BPA free blue foldable eco bottle

>>

Classic Mens Jeans Heavy Washed Custom Leather Patches

>>

Conductive ESD Vinyl PVC Flooring Lab Application Size 600mmx600mmx2.0mm

>>

Svp Fully Automatic Hydraulic Wf67-M CNC Press Brake with Motor and Bearing for Home Use Steel Plate Processing

>>

Bedroom, Bathroom Room, Hotel, Kitchen Pvc Entry Doors Interior Swing Aluminum Alloy Graphic Design Finished 1 YEAR

>>

Mkl 229 Three Roller Driven Wood Sawdust Pellet Pressing Machine

>>

AC Motor Abrasive Sand Impact Crusher (PF1008)

>>

W12S Series 4-Roller Plate Bending Machine Plate Rolling Machine

>>

Yarn Classification Tester with Self-calibration

>>

Manual Mobile Large Foot Pump Type Lifting Table Truck

>>

Used Caterpillar Cat 312b Excavator Japan Original 12tons Second Hand Digger

>>

NZS4211 Wooden Grain Aluminum Slide Mesh Window With Blue Glass

>>

5000W/5kw 5000 Watt 12V/24V/48V DC to AC 110V/120V/220V/230V Pure Sine Wave Power Inverter

>>

4 In 1 Multiport USB 2.0 Hub Multi-function Converter Splitter 4 port usb 2.0 hub adapter for Laptop

>>

Automatic Cattle Dairy Farm Cow Manure Scraper

>>

Good price automatic 5 gallon 20l bottle pure water filling machine

>>

China Factory High Quality Piper Nigrum Extract Piperine Powder 95% 98% CAS 94-62-2 Fabricado En China Food-Additive

>>

Loader Machine for sale

>>

37gsm tape wire dark green knit mesh shade net 30% shading net