|

US$30,000.00-33,000.00

|

1 Set

(MOQ)

|

Basic Info.

Automatic Grade

Automatic

Molding Method

Extrusion Molding

Standard

European Standard

Application Scenarion

Brick Factory

Dimensions

Based on on-Site Inspection

Factory Span

Based on on-Site Inspection

Payment Term

Tt or as Negotiation

Technical Support

Supported

Design Drawings

Supported

Transport Package

Support Land and Sea Transport

Specification

50/50 60/60 70/75 90 120

Production Capacity

200000 Pieces Per Day

Product Description

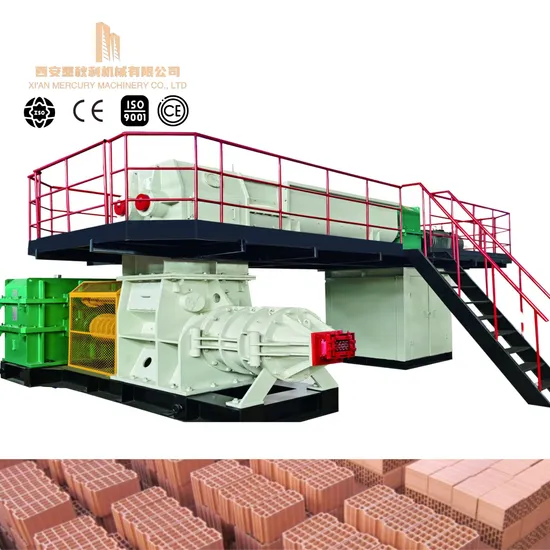

Jkr60/60 Automatic Tunnel Kiln Brick Making Production Line of Brick Making Machine

Product Description

Product Parameters

Technical Parameters

| Model | 3.6 Meter (inner width) |

| Output (standard pcs/day) | 70000-100000 |

| Brick size | 254*115*70mm |

| Firing Cycle (h) | 35-45 |

| Firing pass(%) | 95 |

| Suitable for the products | Suitable for good quality solid bricks & hollow bricks or any kinds of Facing Bricks (high hollow ratio) |

| Coal feeding method | Both automatic and manual is ok |

| Height for dried brick stacking (layer) | 14 layers |

| Automatic Level | High automation level, equipped with fully automatic loading & unloading system |

PRODUCT FEATURE

The production of red bricks mainly includes four steps: raw material preparation, molding, drying, and firing. The production of red bricks mainly the following steps:

1.Raw material preparation: The main raw material for red bricks is clay, and sometimes shale, coal gangue, and other powdery materials are added. The raw materials need to be crushed, mixed, and kneaded to better shape.

2.Molding: The prepared raw materials are pressed into shape through manual or means. In modern production, a brick press is usually used to press the mixed clay and sand into brick blanks of specified size.

3.Drying: The brick blanks after need to be placed in a ventilated and shaded place to dry, usually taking 1-3 days until the surface of the brick blanks is dry and free of stains.

4.Firing: The dried brick blanks are placed in an oven for high-temperature baking, generally requiring a temperature of about 800ºC, lasting 10-15 hours, until they are completely dried and hardened, becoming solid red bricks.

The above is the basic production process of red bricks. It be noted that different manufacturers may have some slight differences, but the overall process is consistent.

Company Profile

Company Information

Xi'an Mercury Machinery Co. , Ltd. is specialized in the brick industry for the whole project design, kiln design, project construction and management etc.. it is one of Xi'an High Tech Enterprises.It starts to explore international market from 2007, and build many brick production lines in Bangladesh, India, Pakistan, Brazil, South Africa, Mozambique, Mexico, Russia, Venezuela,Kazakhstan, Vietnam and other countries. It has been gained many high reputations from customer and partners and constructer. We devotes ourselves to business philosophy of the Pursuit of the Excellent Chinese manufacturing Brand, establish brand awareness and serve awareness among our staff, and provide an one-stop service to customer. We not only produce brick&tile making machine,but also major in and turn-key project forproviding solutions to brick & tile making industry .

After Sales Service

FAQ

1. what's the raw material for producing bricks?

Answer: clay,mud,gangue,shale etc.

2. how much land area for building a new brick plant?

Answer: it need above 20,000 square meters,the land area relate with capacity

3. when you need our proposal and quotation,what you have to mention in your inquiry.

Answer:please provide daily capacity,the brick size and you want to build a new brick plant or brick making machingery only. so we can give the proposal and offer accordingly.

4. what's the Trade terms?

Answer: it can be EXW,FOB,CIF,CNF,FCA,CPT, CIP

>>

Manufacturer Industrial Diesel Engine Wooden Truck Chipping Machinery

>>

5W 5V Custom Round Glass Solar Panel for Solar Bollard Lights

>>

Knapsack Backpack Hand Operated Garden Pressure Sprayer with CE (NS-20A)

>>

Dalian Deyu Three-Roll Calender for Rubber/Plastic 710 X 1800

>>

Home Appliance Quickly Boiling Water Kettle Electric Kettle

>>

CI868K01-eA ABB module inventory spot sale

>>

Special Effect CO2 Jet Machine for Disco Show

>>

Factory Hot Selling Engine Assembly selling well worldwide G4GA Engine Assembly For Hyundai 1.6L G4GA

>>

Hot aluminum alloy doors and Windows inexpensive aluminum alloy roller shutters

>>

Hollow Brick Clay Brick Machine Mould Autoclaved Aerated Concrete Equipment

>>

Hot sale Stainless Steel BBQ Grill for Restaurant

>>

Automatic 1kg 2kg 5kg Rice /Sugar Vertical Small Grain Granule Packing Machine

>>

Anycubic- Photon Mono M5, Upgraded Slicer Software, 12K Resin 3D Printer with 10.1′′ HD Monochrome Screen

>>

Anti-Slip Oil Water Proof Prevent Puncture Steel Toe Men Protection Industrial Work Leather Safety Shoes

>>

Taijia FT8210H Magnetic Flow Meter Converter Meter Sensor

>>

3D Wood Acrylic MDF 3 Axis 4 Axes CNC Engraving Router Machine

>>

Low-Temperature Paint Booth and Drying Equipmenthigh-Performance Automotive Paint Booth System

>>

Non-Standard Customized Products of Cemented Carbide

>>

Haide Apm Multi Crop Thresher China Factory Apm500 Multi Function Corn Thresher Machinery Tractor Power Pto Drive Sheller Corn Thresher

>>

Agriculture Farm Mini Combine Wheat Walking Tractor Windrower Combine Harvester Machine