Basic Info.

Type

Tool Milling Machine

Milling Cutter Type

Angle Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

Artificial

Automatic Grade

Automatic

Certification

CE, ISO 9001

Certificate

CE Certification

Transport Package

Wooden Frame or Wooden Box

Specification

2000*1800*2500mm

Production Capacity

100PCS/Month

Product Description

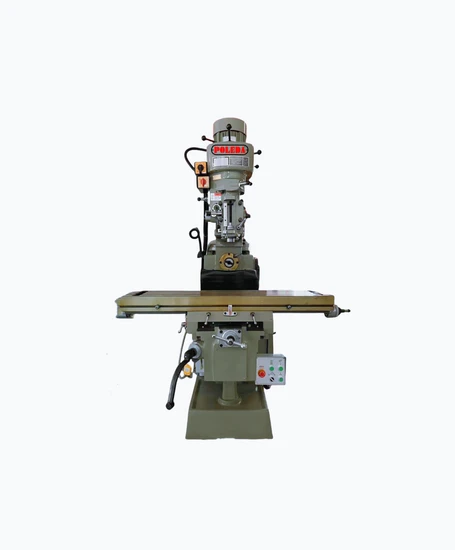

Introducing the POLEDA 5m/5s Universal Vertical Rocker Turret Milling Machine, the epitome of precision and professionalism in the industry. As the leading experts in China, we continuously strive for excellence-there's no best, only better. Discover unparalleled precision with our 5M Vertical Metal Turret Milling Machine.

Experience the superior craftsmanship of the China Universal Milling Machine, brought to you by the most professional team in the field.

In our pursuit of excellence, we believe that there is no best-only an ongoing journey towards better.

Product Description

Product Parameters

Product Introduction

The Turret Milling Machine, also known as a Rocker Arm Milling Machine, Rocker Arm Milling, or Universal Milling, boasts a compact structure, making it small in size yet highly flexible. Its milling head can rotate 90 degrees around and 45 degrees front and back. The rocker arm extends and can rotate 360 degrees on the horizontal plane, significantly enhancing the machine's effective working range.

Construction

The body of the Universal Radial Milling Machine is crafted from high-grade cast iron, ensuring high precision and longevity after artificial aging treatment. The lifting platform incorporates rectangular guide rails with numerous contact surfaces and rigid feet. Following high-frequency treatment and fine grinding, the slide is plastinated for exceptional motion accuracy and durability. The spindle, made from chrome-molybdenum alloy, utilizes precision angular contact bearings, and undergoes tempering and fine grinding for formidable cutting force and high precision.

Applications

The Turret Milling Machine is a lightweight, universal metal cutting machine with both vertical and horizontal milling functions. It can mill flat surfaces, inclined surfaces, grooves, and splines on medium and small parts. This machine is widely used in machining, mold-making, and the instrument and instrument-making industries.

Mechanical Characteristics of Turret Milling Machine

The casting is constructed from m Mihanna cast iron, providing excellent rigidity, stability, and resistance to deformation.

The main spindle is made from chrome-molybdenum alloy and undergoes tempering, heat treatment, and grinding. It is combined with precision bearings, offering robust cutting force and superior precision.

The milling head gear box, made from cast iron, offers good rigidity, minimal deformation, heavier weight for more accurate cutting, and enhanced durability of the milling head.

The three-axis screw cap is made of advanced phosphorus bronze, which provides wear resistance and a long service life.

The XY shaft slide is treated with high wave heat for excellent wear resistance, extending the service life. The XY axis interface, featuring an imported wear-resistant plate, ensures easy operation and durability with a low wear rate.

Equipped with a comprehensive lubrication system, the machine ensures uniform oil distribution, guaranteeing smooth sliding movements.

The machine is 100 kg heavier than similar products, adding to its stability and performance.

With a powerful 5hp motor and a high rigidity, precision NT40 spindle, this machine is perfectly suited for large parts and heavy-duty cutting tasks.

| Product Name | Milling machine |

| Product model | 5M/5S/5HG |

| Product technical parameters | |

| dimension | Table size | 1370*305MM |

journey | Left and right stroke(X) | 800MM |

| Front and rear stroke(Y) | 380MM |

| Up and down stroke(Z) | 380MM |

| Arm reach | 600MM |

| Distance from spindle end face to table surface | 100-480MM

|

| Table bearing | 350KG |

Principal axis coefficient | Spindle taper | NT40 |

| Spindle speed | 80-5440RPM(16-speed) |

| Spindle travel | 127MM |

| Spindle horse power | 5HP |

| Milling head | Milling head tilt Angle | 45° front and back |

| Lead screw | X/Y/Z-axis screw diameter | Tr32/Tr32/Tr35MM |

| Three-axis lead screw pitch | 5MM |

| Machine size (L * W * H)(MM) | 1750*1700*2200MM |

| Approximate machine weight | 1580kgs |

| disposition | Accessories name | quantity |

Standard parts for machine tools | 1,Hand oil pump | 1 |

| 2,Work light | 1 |

| 3,Organ board + protective glue | 1 |

| 4,Lever | 1 |

| 5,Tools and toolboxes | 1 |

| 6,Operating instruction | 1 |

Detailed Photos

Our Advantages

Certifications

FAQ

FAQ

1.What is the MOQ for your production?

A. The MOQ depends on your requirements for color, logo and other customizations. For some standard items in stock, the MOQ is just 1 set.

2.How to control the quality of the products?

A. We have always prioritized maintaining a high-quality standard. Our guiding principle is to delivercustomers superior quality, competitive pricing, and exceptional service.

3.What's your main products of your company?

A: We specialize in a diverse range of machines, such as CNC Machines, Lathe Machines, Milling Machines, Grinding Machines, Vertical Machining Centers, DrillingMachines, Radial Drilling Machines, Sawing Machines, and more.

4. What are your trade terms?

A: Our trade terms include Ex-works, FOB, CFR, and CIF.

5.What are the Payment Terms?

A: T/T, 30% initial payment when order is placed, 70% balance payment before shipment.

6.What CNC system do you use?

A: We use FANUC, SIEMENS, MITSUBISHI, SYNTEC, and HCN systems, depending on your preference.

7.How can I choose the most suitable machines?

A: Send us your product drawings and application details, and we will recommend the most suitable machines for you.

8.What kind of package do you offer?

A. Normally, we use plywood cases to ensure all goods are in excellent condition. Customized packaging is also available upon request.

9.Can your plant do OEM?

A:Yes, we can provide both OEM and ODM services for all customers. 10.How about the warranty?

A: The warranty period is one year after delivery. Beyond this period, we offer lifetime service for the machines.

>>

GF 200eh 200 Ton Injection Making Molding Machine Plastic Bottle Cap Injection Molding Machine

>>

Nr & SBR Synthetic Black 1 2 3 Inch Flexible Water Pump Rubber Suction Hose with High Tensile Helix Steel Wires

>>

Automatic Double Shaft Shredder Machine for Shredding Waste Plastic Lumps/ Pallet/Whole Tyre/Paint Cans

>>

1b/30 Ombre Brown Colored Short Bob Human Hair Lace Frontal Wig 210% density 13x4 Lace Front Wigs For Women

>>

Direct Supplier HPL Melamine Board Waterproof HPL Compact Laminate Gym Locker

>>

2021 Best Selling 009S Usb 3.0 6Pin Pci-E Riser Board Express 1X to 16X Expansion Riser Board Adapter Ver 009S

>>

Ocean Mystery Fresh Rose Real Flowers China Wholesale Yunnan Kunming Base Direct Mail Fresh Cut Flowers Valentine′s Day Wedding Bouquet Wholesale Florist

>>

Hot Sale 8mm Steel Plate Bending Roller Cone CNC Hydraulic Rolling Machine for Pre Rolled Cones

>>

Factory Direct Export 1.60g/cm3 Density Graphite Lubricant Blocks Supplier

>>

PE PP Plastic Film Washing and Recycling Machine

>>

Mobile Concrete Mixer with Self Loader Concrete Mixer Truck

>>

Artificial Quartz Stone Production Line vacuum Vibration Pressing Machine Produce White Quartz Floor Tiles

>>

Hydraulic Four Roller Rolling Machine

>>

Water Heater Pool Collectors Sunrain Thermal Thermodynamic Panel Mauritius Tank Greece Rooftop Tubes Solar Collector

>>

Ore separating concentrator mining thickener

>>

Byloo Wholesale 50Kg 10G Electronic Balance Hand Tools Outdoor Portable Fishing Shopping Scales LCD Display Digital Scale

>>

By-8001 Six-door locker

>>

XCMG Official Xg0807HD 8m Used Mobile Hydraulic Scissor Lift Platform Price

>>

Cheap Aluminum Mini Style Alloy Charging Type C to 4 Ports USB 3.0 USB 2.0 Hub

>>

Digital Lock for Wooden Cabinet