|

US$1,000.00-50,000.00

|

1 set

(MOQ)

|

Basic Info.

Application

Machinery & Hardware, Chemical, Construction, Mineral Industry, Stone Industry

Crushing Style

Grinding & Impact

Compressive Strength (For Crushing)

>300MPA

Crushing Degree

Fine Grinding Machine

Finished Surface

Hole Process

Transport Package

Standard Container

Production Capacity

50-260t/H

Product Description

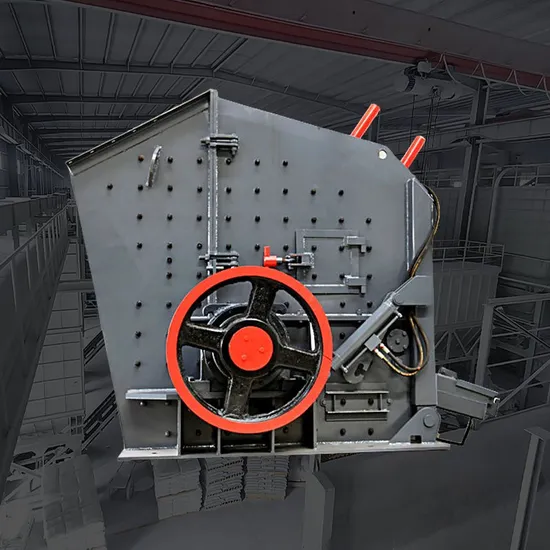

Product Overview

Advantages

1. The High Capacity VSI Impact Crusher is extensively utilized across a myriad of industries including metallurgy, mining, chemistry, cement production, construction, refractory materials, and ceramics.

2.Crafted with precision, the hammer boasts high chrome material, while the liner board is constructed from exceptionally durable materials, ensuring longevity and resilience.

3.This crusher features a uniquely engineered tooth impact plate, meticulously designed for superior performance in crushing hard rock, optimizing efficiency while minimizing energy consumption.

4.Engineered to perfection, the final products exhibit a cubic shape, and the discharge opening is easily adjustable, offering versatility.

5.Designed for simplicity, it streamlines the crushing flow chart, enhancing operational efficiency.

Application

The Impact Crusher stands as a robust solution primarily for the crushing of various mining stones. It can endure a maximum compression resistance of up to 320Mpa. Its versatility makes it a staple in mining, metallurgical industries, construction materials, as well as highway and railway projects. This machine effectively breaks materials into both medium and fine sizes, meeting diverse requirements.

Working principle

The Impact Crusher harnesses the power of striking energy to crush materials, ensuring maximum efficiency.

1.Upon activation, the motor propels the rotor at a high velocity, with the blow bar strategically installed to maximize impact.

2.As materials enter the blow bar's impact zone, they are immediately struck and propelled towards the surrounding impact devices near the rotor.

3.The swift action forces the material to rebound from the impact liner back into the blow bar's effect area until the desired size is achieved.

4.Adjustments can be made between the impact rack and rotor to tailor the size and shape of the end product to precise specifications.

Crusher Model

Main technical parameters

| Modle | Size

(mm) | Feeder Size

(mm) | Input Size

(mm) | Capacity

(t/h) | Motor

(kw) | Weight

(ton) |

| PF-0608 | 644*740 | 320*770 | ≤100 | 10-20 | 30 | 4 |

| PF-0807 | 850*700 | 400*730 | ≤300 | 15-30 | 30-45 | 8.13 |

| PF-1007 | 1000*700 | 400*730 | ≤300 | 15-60 | 37-55 | 9.5 |

| PF-1010 | 1000*1050 | 400*1080 | ≤350 | 50-90 | 55-75 | 14 |

| PF-1013 | 1000*1300 | 650*1350 | ≤350 | 80-120 | 90-110 | 12 |

| PF-1210 | 1250*1050 | 400*1080 | ≤350 | 70-130 | 110-132 | 17 |

| PF-1214 | 1250*1400 | 400*1430 | ≤350 | 90-180 | 132-160 | 22 |

| PF-1315 | 1320*1500 | 860*1520 | ≤400 | 120-250 | 180-260 | 26 |

| PF-1320 | 1320*2000 | 860*2030 | ≤500 | 160-350 | 300-375 | 30 |

Other Products Offered

Company Profile

Company brief introduction

SHANGHAI CLIRIK MACHINERY CO., LTD, situated in the vibrant PUDONG New District of Shanghai, China, is a trailblazing enterprise dedicated to the research, manufacturing, and sales of a comprehensive range of grinding mills and crushers. With expertise spanning from coarse to ultra-fine grinding mills, along with auxiliary equipment like powder modifying machines, packing machines, and conveying systems, we have committed over 30 years to the grinding sector. Our specialization and focus drive our professional acclaim.

We pride ourselves on maintaining a cutting-edge production line, characterized by intelligent, standardized testing and controlling laboratories. Our dedicated team excels in R&D, production, sales, and service, ensuring unparalleled quality and innovation.

our service

We invite you to provide details of your product needs and contact information for a seamless collaboration. As a leading machine manufacturer in China with three decades of experience, we are poised to assist you. Kindly review the information below to select the most suitable machine, and let us furnish you with tailored technical data, quotations, and solution drawings.

our certificate

our exhibition

customer visiting

FAQ

1. What is the raw material do you want to process?

2. What is the capacity per hour do you need?

3. What is the raw material input size?

4. What is the output size of your product?

31e10e5c

>>

China Top Quality Ophthalmic Equipment Digital Slit Lamp for Ophthalmology

>>

3W Portable Mini Desktop Metal laser Engraving and Cutting Machine For wood/ Leather/Bamboo/Food/Plastics/Kraft |Paper/Painted Meta/Ceramics/Glass

>>

Stainless Steel Cooling Jacket Liquor Storage Pot with Side Manhole

>>

M6284F1013 MODUTROL IV control motor

>>

Waterproof China Stage Lighting Factory IP65 24PCS 15W LED Moving Head Outdoor Wash Light

>>

ABB OCAHG 492838402 controller brand new

>>

mindray dp10 mindray ultrasound scanner price with 12 inch LED screen

>>

ISDE Engine Urea Injection Line 5286725 for yutong bus

>>

Factory Directly Sell Hydraulic 46" Ride-on Power Trowel with Kohler Engine

>>

High Quality CE Certificate 2000kg Mini Digger Zero Tail 2t Crawler Mini Excavator Mini Pelle

>>

9-0727S Auto Spare Parts Timing Chain Kit for Ford Transit 2.0L TK4020

>>

Pandora New Plastic 20L Rociador Agricultural Backpack Battery Sprayer Electrically Agricultural Knapsack Hand Manual and Battery Power Pressure Backpack

>>

High BFE Disposable Medical Face Mask XINGRONG

>>

Core Material Hot Press Machine for Panels

>>

Rubber Vulcanizing Press Machine/Rubber Vulcanizer Press

>>

12V Electric SUV Car for Kids with Parental Remote Control

>>

C828 Linear Motor CNC Grinding Machine for Carbide Cutting Tools Application CNC Tool Grinder

>>

Assembling Work Glove Production Machine

>>

Hot Sale High Capacity Maize Shelling Machine Corn Sheller Thresher for Sale

>>

CNC High Speed CNC Drilling Machine for Beams